Magnum Venus Plastech INNOVATOR II CONTROL UNIT User Manual

Page 18

INSTALATION/OPERATIONS MANUAL

INNOVATOR II

MAGNUM VENUS PLASTECH

REV 1.40

MAY 2012

PAGE 18

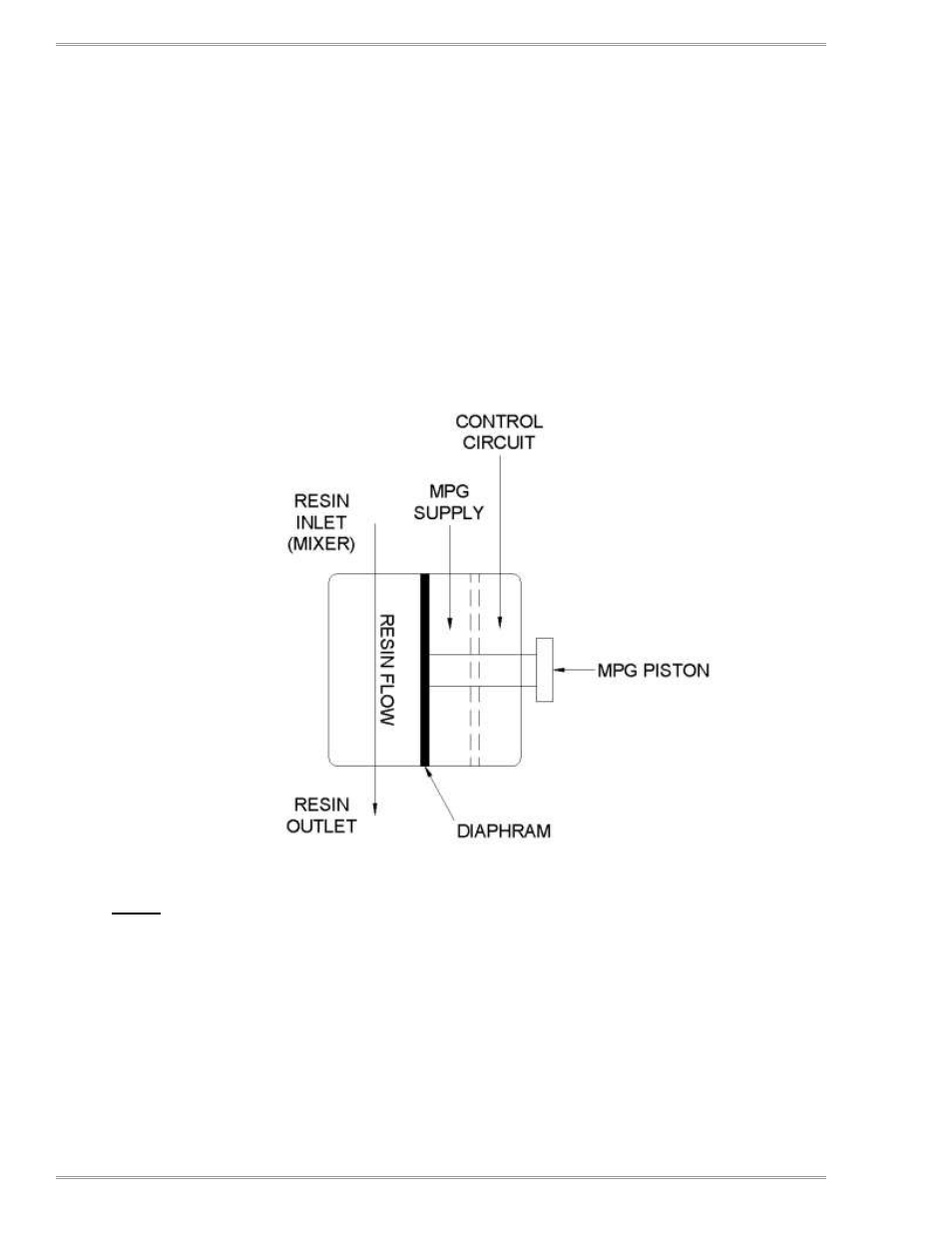

Mold Pressure Guard (MPG)

The machine features a Mold Pressure Guard (MPG), which is used to control the maximum allowable pressure at the

mixing head. This can be utilized to provide line pressure control during an injection, or as a safety mechanism to prevent

the line pressure from exceeding the maximum working pressure of the injection line to the mold.

The MPG block is supplied with 2 air lines. One air-line supplies air from the MPG pressure regulator on the control panel.

The other is connected to an internal circuit on the control box.

When fluid pressure at the injection head exceeds the MPG preset level, shown on the MPG pressure gauge, the internal

diaphragm moves the MPG piston outward and leaks air from the line connected to the control circuit.

As the level/flow of air pressure is reduced by the MPG the piloted regulator, the supply pressure to the pump is reduced,

in effect slowing it down. Once the air pressure in the control circuit has dropped below approximately 15 psi, the pump

will shut off. In the case of the Pro gun configuration, the gun will also close. Once the pressure has been restored, either

by fluid being drawn into the mold, recirculation engaged or blockage cleared from output line, the system will start up

again.

FIG 4.20

NOTE: The MPG control is active in recirculation or injection mode. It is normal to hear air leaking from the MPG

block when the MPG is operational.