General information, Pod models, Output signal resolutions – Liquid Controls POD User Manual

Page 4

General InformatIon

General Information

The Liquid Controls Pulse Output Device (POD) converts the rotary motion of the Liquid Controls Positive

Displacement Flowmeter into electronic pulses. This allows the meter to interface with a wide variety of electronic

monitoring devices and control equipment. The POD operates in standard and bidirectional flow applications.

The POD mounts directly to the front cover of any Liquid

Controls meter in place of the packing gland. The motion of

the meter’s blocking rotor is magnetically coupled through

a stainless steel wall to the electronics compartment of the

POD. This eliminates the dynamic seal of the packing gland

and isolates the electronics from the process fluid in the

meter.

Inside the electronics compartment, an optical shaft encoder converts the rotary motion into a high resolution, two-

channel, quadrature square wave. Both outputs are driven by field effect transistors (FETs) and switch from zero

volts in the “ON” state to the user’s power supply voltage in the “OFF” state. As supplied from the factory, there is a

2.2KΩ pull-up resistor on each output which can be removed from the circuit in the field to produce a true “open drain”

output. As open drain devices, the outputs can sink up to 100 mA in the “ON” state and sustain up to 30 VDC in the

“OFF” state.

The electronics compartment also serves as a conduit junction box. The POD has an O-Ring sealed, threaded cover.

The standard wire entrance is a ½-14 NPT female hub which accepts threaded conduit or a cable gland. A screw-

type, removable, terminal block on the circuit board facilitates wiring of the unit. With the wiring entrance sealed and

the cover in place, the housing has a weatherproof rating of NEMA 4X.

Pod models

There are five POD models available.

Pod1

Fork Drive with Buna-N O-Ring,

100 PPR Quad Pulser, 9 to 30VDC

Pod2

Fork Drive with PTFE O-Ring,

100 PPR Quad Pulser, 9 to 30VDC

Pod3

Blade Drive with Buna-N O-Ring,

100 PPR Quad Pulser, 9 to 30VDC

Pod4

Blade Drive with PTFE O-Ring,

100 PPR Quad Pulser,

9 to 30VDC

Before installation, check your shipment against the

packing list and ensure that no parts are missing. The

packing list is inside the red information packet along with

the Installation and Operation Manuals.

Check Each Shipment

ms series

Meter

Pulses/

Gallon/

Channel

single channel

Pulses/

litre/

Channel

single channel

Max outPut

- khz

@ max flow rate

(GPM)

MS-7

555.5

146.8

0.93

MS-15

205.8

54.4

0.69

MS-25

205.8

54.4

1.03

MS-30

74.2

19.6

0.43

MS-40

74.2

19.6

0.56

MS-75

25.5

6.7

0.30

MS-120

15.8

4.2

0.26

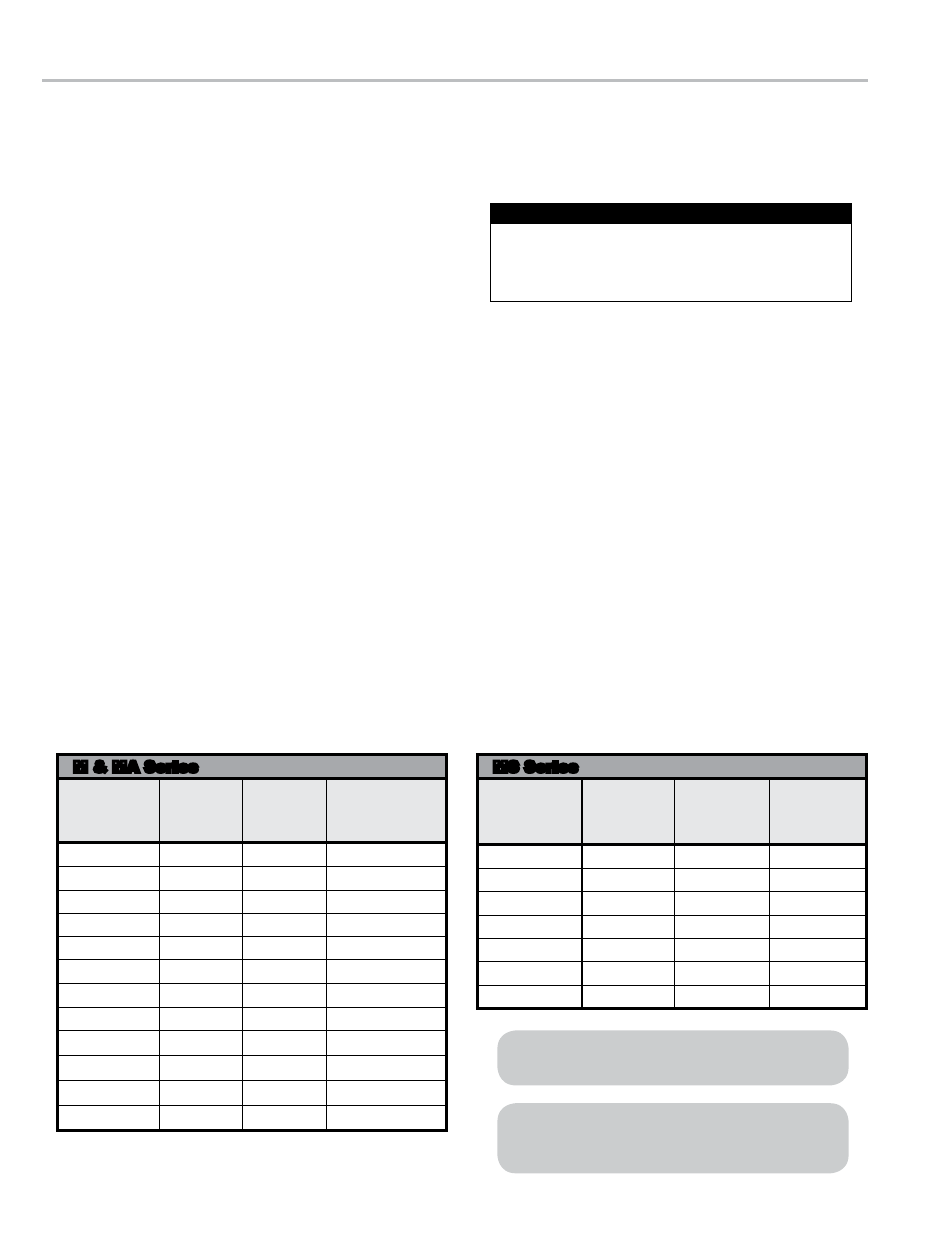

m & ma series

Meter

Pulses/

Gallon/

Channel

single channel

Pulses/

litre/

Channel

single channel

Max outPut - khz

@ max flow rate

(GPM)

MA-4

1,223.7

323.4

1.22

M-5, MA-5

(3:1)

407.9

107.8

0.41

M-5, MA-5

(1:1)

1,223.7

323.4

1.22

M-7, MA-7

555.5

146.8

0.93

M-10

555.5

146.8

1.39

M-15, MA-15

205.8

54.4

0.69

M-25

205.8

54.4

1.03

M-30

74.2

19.6

0.43

M-40

74.2

19.6

0.53

M-60

new style

39.8

10.5

0.40

M-60

old style

25.5

6.7

0.26

M-80

39.8

10.5

0.53

Output Signal Resolutions

Pod5

Fork Drive with Buna-N O-Ring,

100 PPR Quad Pulser, 5 to 24VDC

If using both channels and rising edge only, multiply the

pulses per unit and maximum kHz by a factor of two.

For LCR applications using both channels and the

rising and falling edge, multiply the pulses per unit and

maximum kHz by a factor of four.

4