Owner’s information packet, Installation requirements – Liquid Controls MA4 Meter User Manual

Page 4

4

Owner’s Information Packet

Is all your documentation included with your meter? LC

meters come in many variations. The information sent to

you depends on the accessories you have ordered with

your meter. Make an inventory of your Owner’s

Information Packet. First, find your LC packing slip with

the computer printout. Locate the serial number and the

meter model number on this printout. Cross-reference

the packing slip with the actual meter serial numbers.

Included in your Owner’s Information Packet are the

following:

•

Installation and Parts Manual

•

Bill of Materials

•

SCAMP™ Installation and Operation Manual

Record your meter serial number in the space provided

on the inside cover of this manual. The inside cover also

provides a space for your full-service distributor’s name

and telephone number, if applicable. Fill in this

information and keep it handy. You will always need your

meter serial number and model number when calling for

service or parts. See “How to Order Replacement Parts”

on Page 27 in this manual.

Installation Requirements

!

!

!

!

! WARNING

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

•

Make sure that all necessary safety precautions

have been taken. Provide for proper ventilation,

temperature control, fire prevention, evacuation,

and fire management.

•

Provide easy access to the appropriate fire

extinguishers for your product. Consult with your

local fire department and state and local codes to

make sure that you are adequately prepared.

•

Read this manual as well as the literature provided

in your Owner’s Information Packet. If you have any

questions, consult with your full-service distributor

or call the Service Department at Liquid Controls.

•

Install the meter and accessories in conformance with

all applicable federal, state, local, construction,

electrical, and safety codes.

•

Class 10 meters for LPG must be installed in

accordance with the requirements of ANSI-NFPA 58

in addition to all other state and local codes.

•

Under normal operation, do not expose any portion

of the LP-Gas system to pressures in excess of rated

working pressures without an automatic safety valve

to vent the over pressure discharge to a place of

safety away from the operator and other people.

Failure to provide such a safety relief may result in

leakage or rupture of one or more of the components

in the system. This can result in injury or death from

the gas, a fire, or pieces of flying debris from the

rupture.

•

Before shipment, protective thread caps were placed

in all meter and accessory openings. They should

remain in place until you are ready to attach piping.

•

Prior to meter installation, the entire piping system

should be thoroughly flushed of all debris, with a liquid

that is compatible with the construction of the meter.

•

Keep all external surfaces of the meter clean.

•

Apply pipe compound to male threads only.

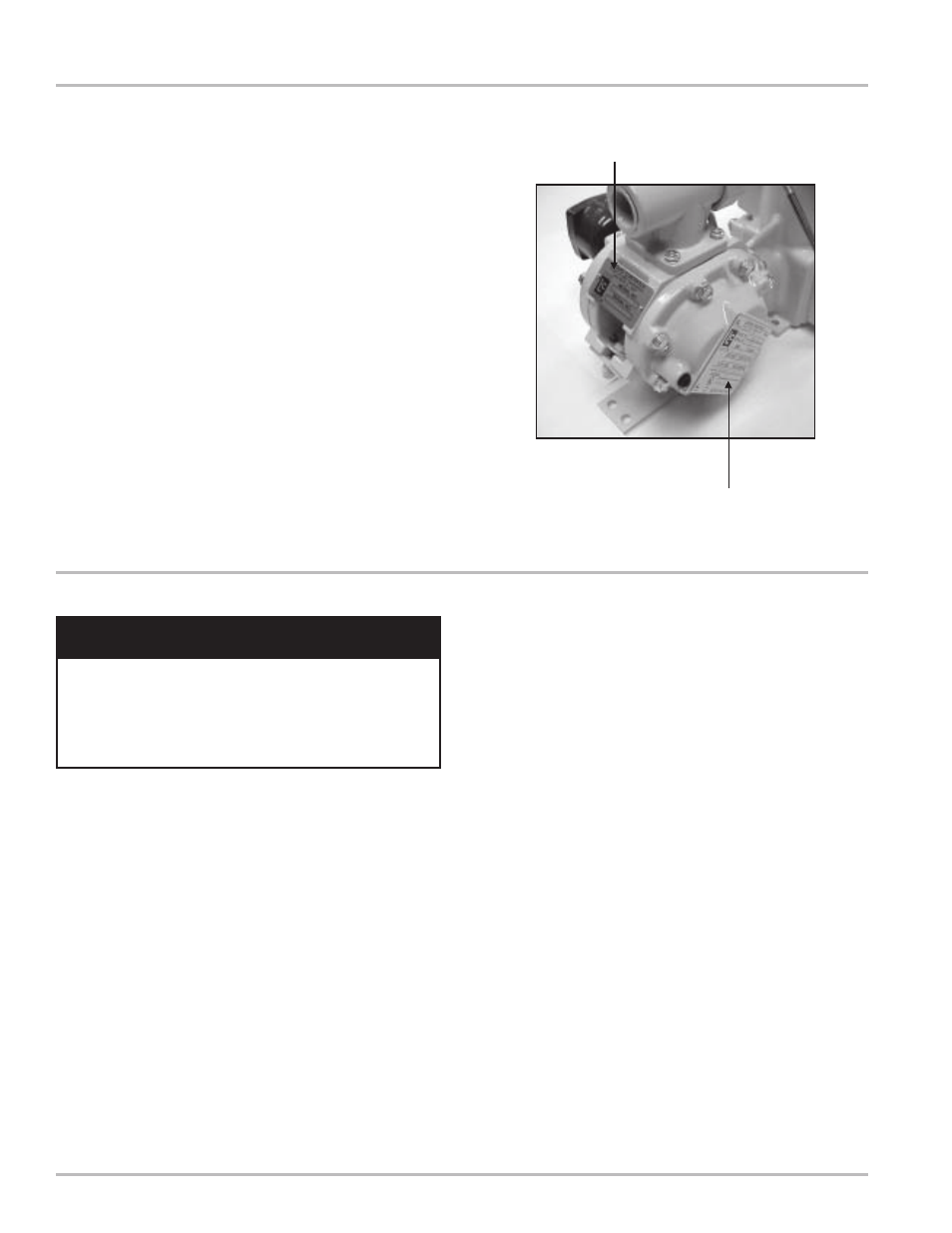

Serial Number Plate (Rear)

Serial Number Plate (Side)