How lc meters work – Liquid Controls MA4 Meter User Manual

Page 3

3

How LC Meters Work

Liquid Controls meters are positive displacement meters.

They are designed for liquid measurement in both

custody transfer and process control applications. They

can be installed in pump or gravity flow systems. Because

of their simple design, they are easy to maintain, and

easy to adapt to a variety of systems.

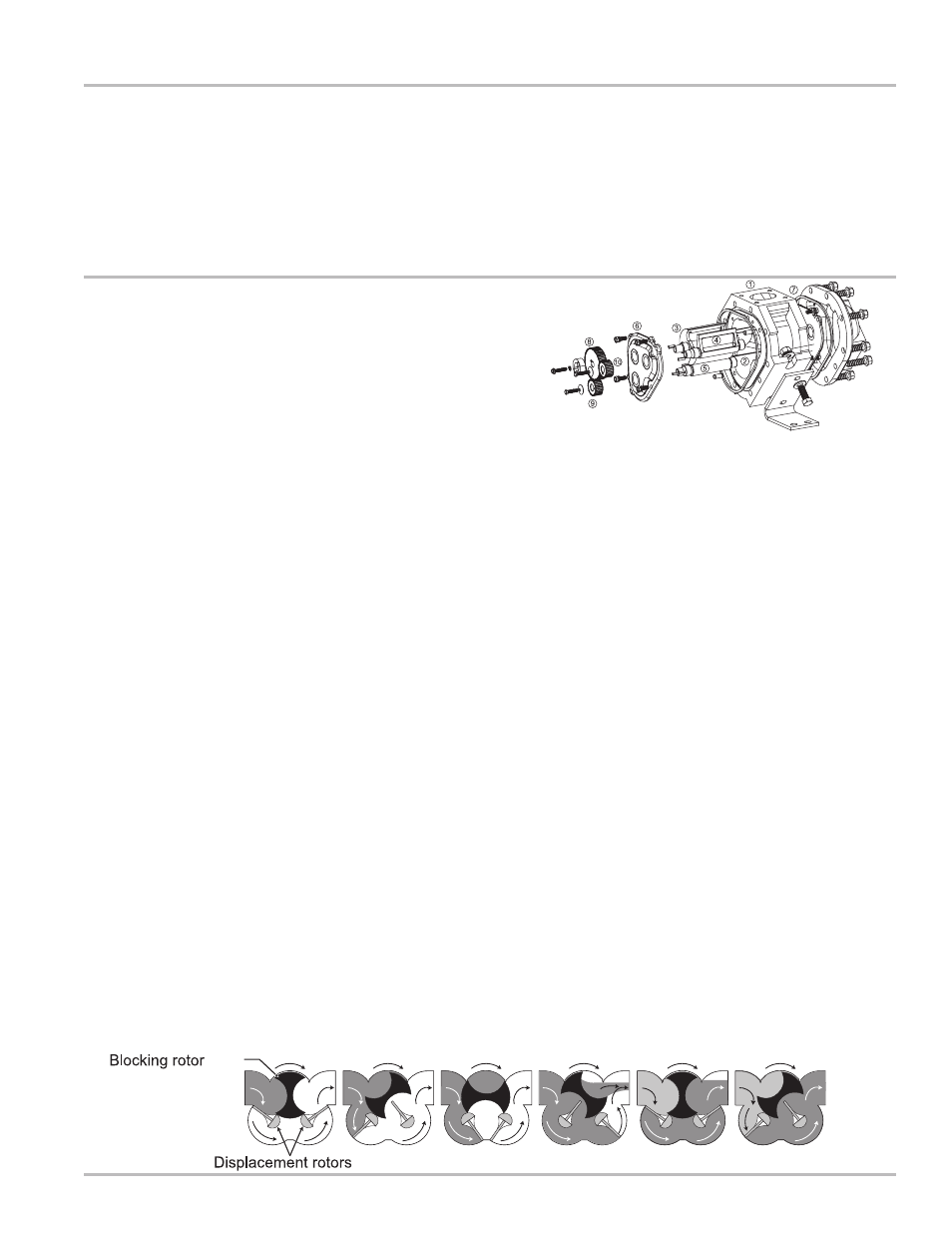

The meter housing (1) is designed with three cylindrical

bores (2). Three rotors, the blocking rotor (3) and two

displacement rotors (4, 5), turn in synchronized

relationship within the bores. The three rotors are

supported by bearing plates (6, 7). The ends of the

rotors protrude through the bearing plates. Blocking rotor

gear (8) is placed on the end of the blocking rotor.

Displacement rotor gears (9, 10) are placed on the ends

of the displacement rotors. These gears create the

synchronized timed relationship between the three rotors.

As fluid moves through the meter housing, the rotor

assembly turns. The liquid is broken into uniform sections

by the turning rotors. Fluid displacement happens

simultaneously. As fluid enters, another portion of the

fluid is being partitioned and measured. At the same

time, the fluid ahead of it is being displaced out of the

meter and into the discharge line. Since the volume of

the bores is known, and the same amount of fluid passes

through the meter during each revolution of the blocking

rotor, the exact volume of liquid that has passed through

the meter can be accurately determined.

This true rotary motion is transmitted through the packing

gland, the face gear, the adjuster drive shaft, and the

adjuster to the register stack and counter. True rotary

motion output means consistent accuracy since the

register indication is in precise agreement with the actual

volume throughput at any given instant.

At any position in the cycle, the meter body, the blocking

rotor, and at least one of the displacement rotors form a

continuous capillary seal between the un-metered

upstream product and the metered downstream product.

Capillary seals mean no metal-to-metal contact within

the metering element. This means no wear. No wear

means no increase in slippage, and no increase in

slippage means no deterioration in accuracy.

Throughout the metering element, the mating surfaces

are either flat surfaces or cylindrical faces and sections

that are accurately machined. These relatively simple

machining operations, plus the fact that there is no

oscillating or reciprocating motion within the device,

permits extremely close and consistent tolerances within

the LC meter.

The product flowing through the meter exerts a dynamic

force that is at right angles to the faces of the

displacement rotors. The meter is designed so that the

rotor shafts are always in a horizontal plane. These two

facts result in no axial thrust. Therefore, with no need

for thrust washers or thrust bearings, the rotors

automatically seek the center of the stream between the

two bearing plates eliminating wear between the ends

of the rotors and the bearing plates. Once again, no

wear results in no metal fatigue and no friction.

The Liquid Controls meters are made of a variety of

materials to suit a variety of products. Because of our

no-wear design, capillary seals, and unique rotary

metering, LC meters provide unequalled accuracy, long

operating life, and unusual dependability.

4.

See that the gas is dispersed before resuming

business and operating motors. If in doubt, notify

your local fire department.

In the Event of a Gas Fire

In the event of large fires or fires that are spreading:

Evacuate the building and notify your local fire

department. Stop the leakage only if you can safely reach

the equipment.

In the event of small, contained fires that you can

safely control: Stop the leakage if you can safely reach

the equipment. Then use the appropriate extinguisher:

Class B fire extinguisher, water, fog, etc., depending on

the materials. If in doubt, call your local fire department.

Meter Element Exploded View