Differential valve maintenance, Disassembling the valve – Liquid Controls MA4 Meter User Manual

Page 17

17

Differential Valve Maintenance

Faulty operation of the differential valve may be caused

by defective valve seals, the spring, or the diaphragm.

The diaphragm and the O-Ring valve seat are the only

parts that should require replacement in normal service.

It is not necessary to remove the valve from the line for

disassembly.

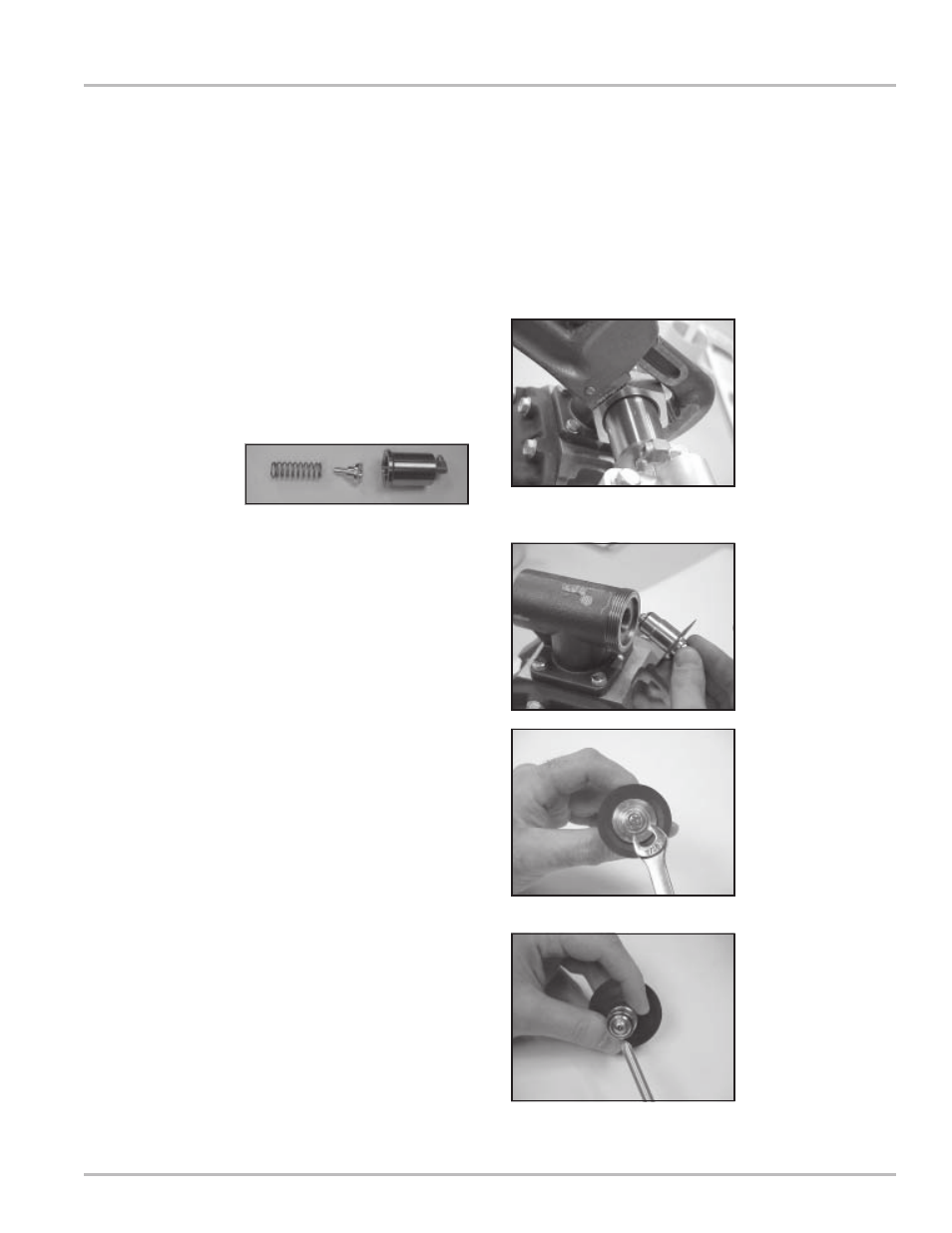

Disassembling the Valve

1.

Remove connecting tube between differential valve

and vapor eliminator cover. See illustration on Page

15.

2.

Unscrew the union nut and remove the spring case,

limit stop, and spring from the body.

3.

Remove the diaphragm and piston assembly.

4.

The diaphragm can be inspected by unscrewing the

nut and removing the diaphragm head.

5.

Inspect the diaphragm for cuts, tears, or pinhole

leaks. Replace if defective. Caution: Do not over

tighten diaphragm retaining nut. Torque

diaphragm retaining nut to 18-20 inch-lbs.

6.

Check the O-Ring and replace if necessary.

7.

Reinstall piston assembly into body, insert spring,

limit stop, spring case and union nut.

8.

Reassemble connecting tube.