Vapor eliminator & strainer maintenance, Disassembling and assembling – Liquid Controls MA4 Meter User Manual

Page 15

15

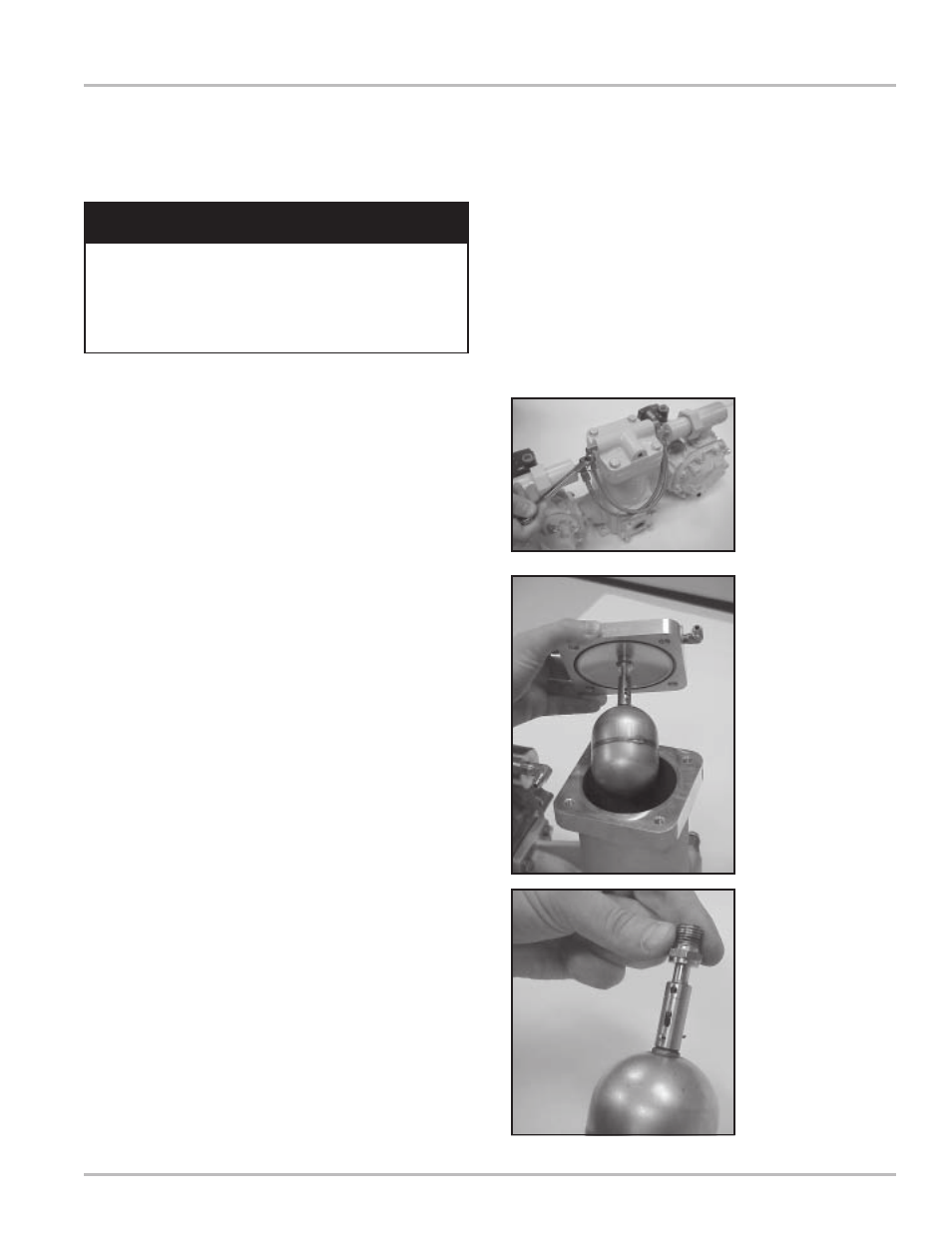

Vapor Eliminator & Strainer Maintenance

Servicing of the vapor eliminator and strainer involves

occasional cleaning of the strainer, or, when required,

replacing a float or sticking valve.

!

!

!

!

! WARNING

All internal pressures must be relieved before

disassembly or inspection of the strainer, air eliminator,

any valves in the system, the packing gland, and the

front or rear covers. See “Relieving Internal Pressure”

(Page 10).

Disassembling and Assembling

1.

Disconnect the tubing between the differential valve

and vapor eliminator cover. For the dual meter

system, this may require removal of two segments

of tubing.

2.

Remove the four screws on the Vapor Eliminator

cover. Lift the cover to inspect the internal float

assembly. Be careful not to damage the O-Ring seal.

3.

If the float is crushed or damaged, remove cotter pin

and replace float.

4.

Carefully inspect the sleeve valve for any resistance

to smooth movement of the sleeve on the stem.

Inspect all holes in the sleeve and the stem for foreign

material, which could cause sticking of the valve

and obstruct the flow through the valve. With the float

removed, the sleeve must move on the stem by its

own weight. If defective, replace sleeve and stem

assembly. Note: The vent hole is larger than the

cotter pin hole used to attach the sleeve to the float.

If replacing the sleeve, ensure that the sleeve is in

the correct orientation with the larger hole on top.