Installing the system, Preliminary checks, Foundation plate installation – Controlled Products Systems Group 109837 User Manual

Page 9: Mechanical installation

9

FAAC MODEL 844 Slide Gate Operator

2

8 ¾

0 to 2

- Measurements in Inches

2.5

- Measurements in Inches

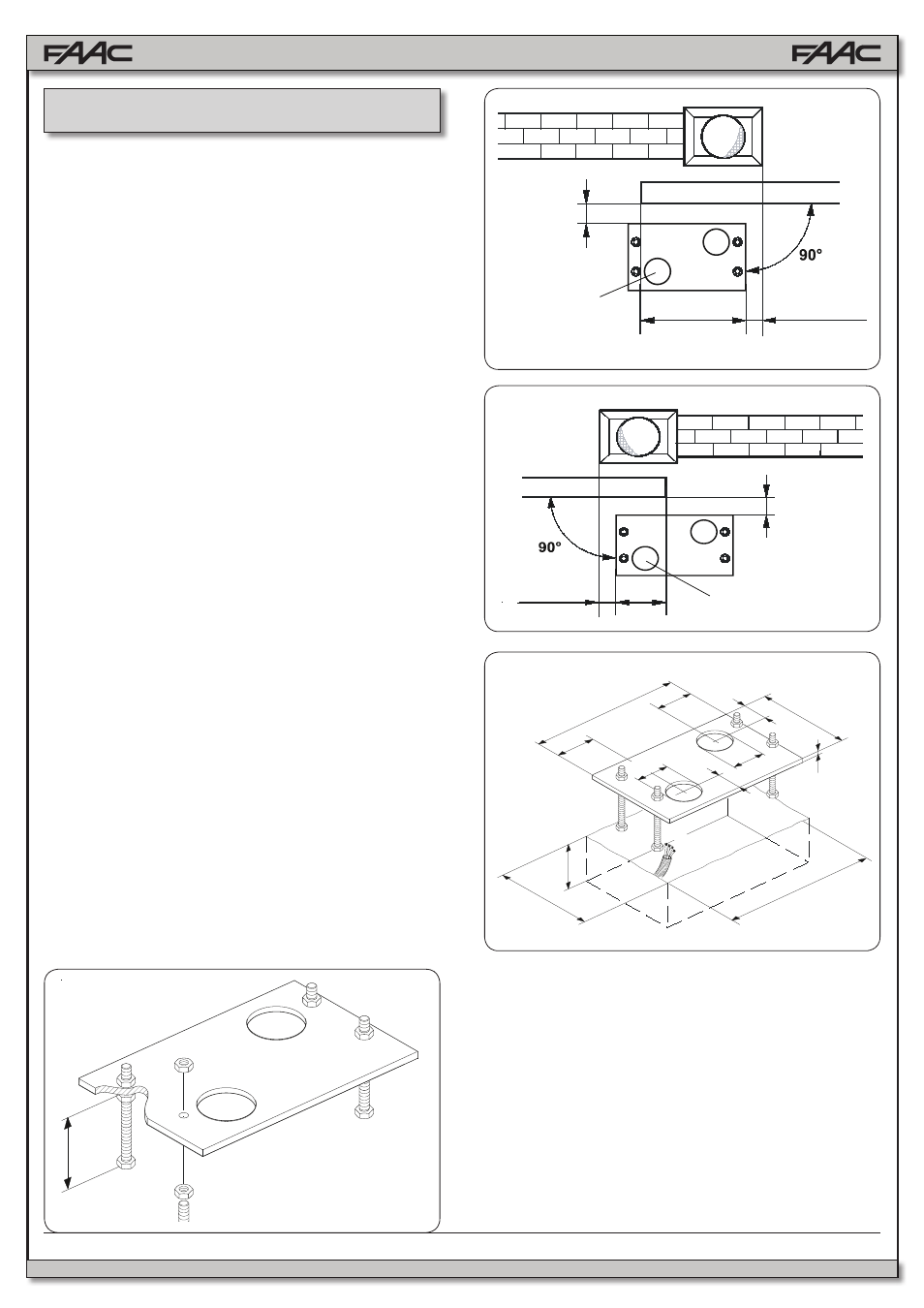

Fig. 4

Fig. 5

Fig. 7

4.1.

PRELIMINARY CHECKS

To ensure safety and an efficiently operating automated

system, make sure the following conditions are observed:

• The gate structure must be suitable for automation. For

example, wheel diameter must be in proportion to the

weight of the gate to be automated, an upper guide must

be provided, mechanical stop limits to prevent the gate

derailing must be installed.

• The soil must permit sufficient stability for the concrete

pad.

• There must be no pipes or electric cables in the pad

excavation area.

• If the operator is exposed to passing vehicles, install, if

possible, adequate means of protection against acciden-

tal impact.

• Check if an efficient grounding is available for connec-

tion to the gearmotor.

4.2.

FOUNDATION PLATE INSTALLATION

1. Assemble the foundation plate as shown in Fig 4. The

foundation plate must be located as shown in Fig 5 (right

closing) or Fig 6 (left closing) to ensure that the rack and

pinion mesh correctly.

2. Prepare a concrete pad as shown in Fig.7, following

the suggested dimensions. It’s recommended to have

the pad a minimum of 4” above level grade to avoid any

flooding of the operator. The underground depth of the

concrete pad is determined by the soil condition and

the local building codes. Make sure the concrete pad is

leveled.

3. Provide one or more conduit pathways for all power and

accessory connections. Extend the conduit about of 1/2”

above the level of the concrete pad.

4. After the concrete is poured in the forms and before it

has a chance to set, insert the foundation plate into the

cement and position it flush with the top of the concrete

and aligned with the top of the lower gate frame. Use the

dimensions shown in Figs 5 or 6 to align your founda-

tion plate. Allow the concrete to set for a minimum of two

days before installing the operator.

5. Route the wires in the conduits. To facilitate the connec-

tions allow for about 15” of extra length of cables out of

the conduit. Separate the high and low voltage wires in

different conduits.

1. Assemble the mounting brackets and anti-vibration spac-

ers on the operator as shown in Fig. 8.

2. Open the cover, remove the securing screws.

3. Attach the operator to the plate, using the supplied wash-

ers and nuts as shown in Fig. 9.

4. During this operation, route cables through the opening in-

side the lower half-casing of the operator (Fig.10 - Ref. A).

To access the electronic equipment, route the cables through

the appropriate hole, using the supplied rubber cable-clamp.

Make sure to strip the jacket on all cables so that the clamp

holds single cables only (Fig.10 - Ref. B).

4.

INSTALLING THE SYSTEM

0 to 2

2

6

- Measurements in Inches

Fig. 6

11.5

1.75

1.75

6.25

3

3

2⅜

2⅜

4

7

12.25

0.25

- Measurements in Inches

4.3.

MECHANICAL INSTALLATION