Manual operation 9. restoring normal operation, Maintenance 12. repairs – Controlled Products Systems Group 109837 User Manual

Page 21

21

FAAC MODEL 844 Slide Gate Operator

Fig. 49

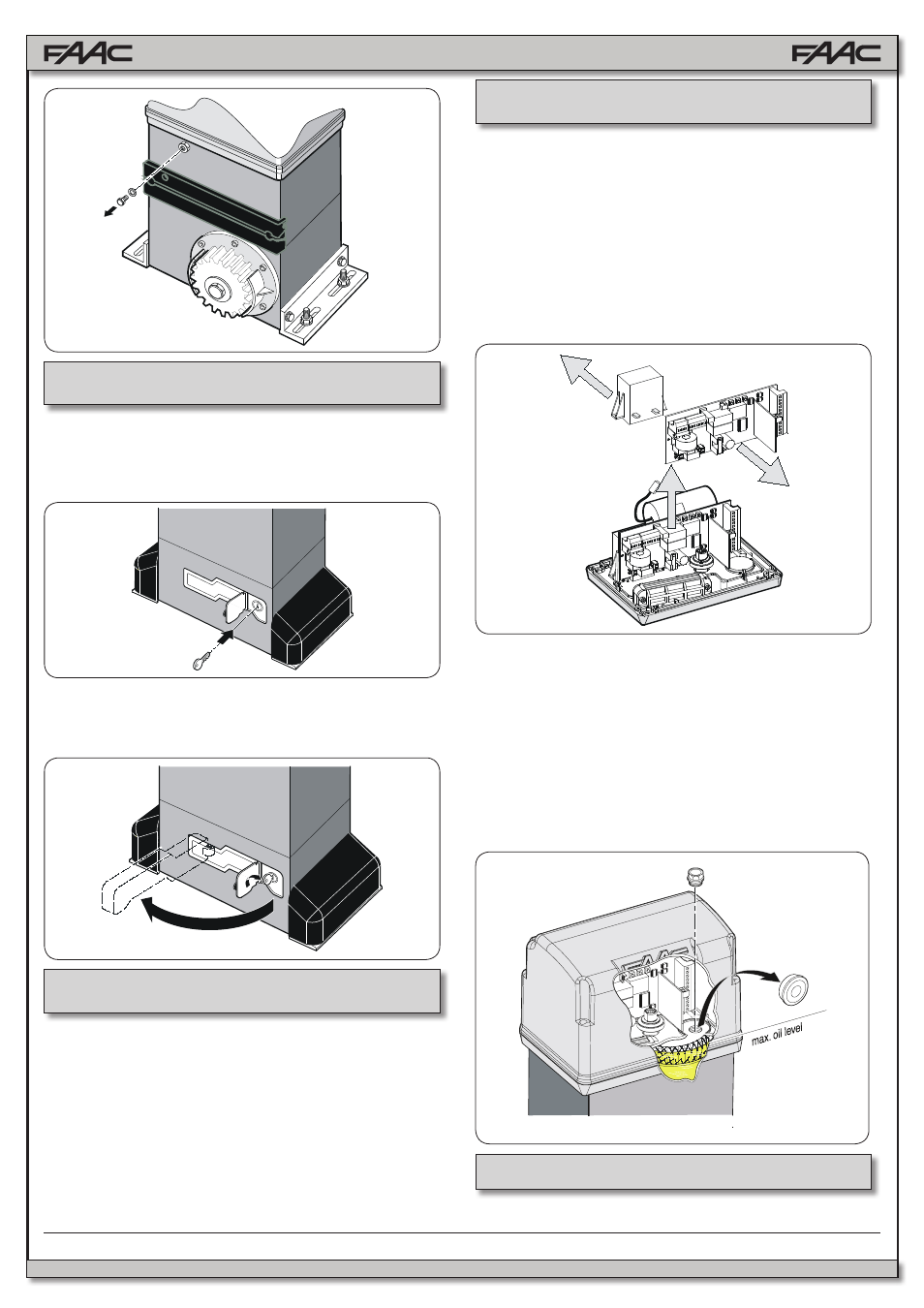

To prevent an involuntary pulse from activating the gate, cut

power to the system before re-locking the operator.

1. Re-close the release lever.

2. Turn the key counter-clockwise

3. Remove the key and close the lock protection door.

4. Move the gate until the release engages.

If the gate has to be operated manually due to a power blackout or

malfunction of the automated system, use the release device as fol-

lows:

1. Open the protection door and insert the supplied key in the lock

(Fig. 48).

2. Turn the key clockwise and pull the release lever as shown in Fig.

49.

3. Open and close the gate manually.

Fig. 47

Fig. 48

8.

MANUAL OPERATION

9.

RESTORING NORMAL OPERATION

Fig. 54

Fig. 53

For any repairs, contact an FAAC authorized repair center.

Check the operational efficiency of the system at least once eve-

ry 6 months, especially the efficiency of the safety and release

devices (including operator thrust force).

11.1.

DISASSEMBLING THE TRANSFORMER-

BOARD UNIT

If you have to disassemble the transformer-board unit,

proceed as follows:

Remove all terminal boards and connectors from the board.

Unscrew the 3 screws from the board and the 2 from the

transformer. Lift the unit up and gently remove the transformer

from the couplings on the board as shown in Fig. 53.

11.2.

OIL TOP-OFFS

Periodically check the oil level inside the operator.

A once-a-year check is enough for medium or low usage. For

heavy duty usage, a check every 6 months is recommended.

To access the tank, temporarily remove the plastic oil filler cap

(Fig. 54).

Oil level is visually checked and must cover the copper coil of

the electric motor.

If more oil is needed, add it through the oil filler hole.

Use FAAC XD 220 oil only.

10. MAINTENANCE

12. REPAIRS