Model 844 operator, Description & specifications – Controlled Products Systems Group 109837 User Manual

Page 7

7

FAAC MODEL 844 Slide Gate Operator

MODEL 844 OPERATOR

These instructions apply to the following models:

844 ER Z16 CR, 844 R, 844 R CAT, 844 R RF

The FAAC Model 844 automated system for sliding

gates is an electro-mechanical operator transmitting

motion to the sliding leaf via a rack or chain pinion

appropriately coupled to the gate.

The non-reversing system ensures the gate is

mechanically locked when the motor is not operating

and, therefore, no lock needs to be installed.

The gearmotor is equipped with a mechanical

clutch which, combined with an electronic device,

offers the necessary adjustable anti-crushing

safety and guarantees stopping or reversing the

gate movement. A handy manual release makes it

possible to move the gate in the event of a power

cut or malfunction. The control board, if supplied

with the gearmotor, it is placed inside the operator.

The 844 automated system was designed and

manufactured to control access of vehicles. Avoid

any other use whatever.

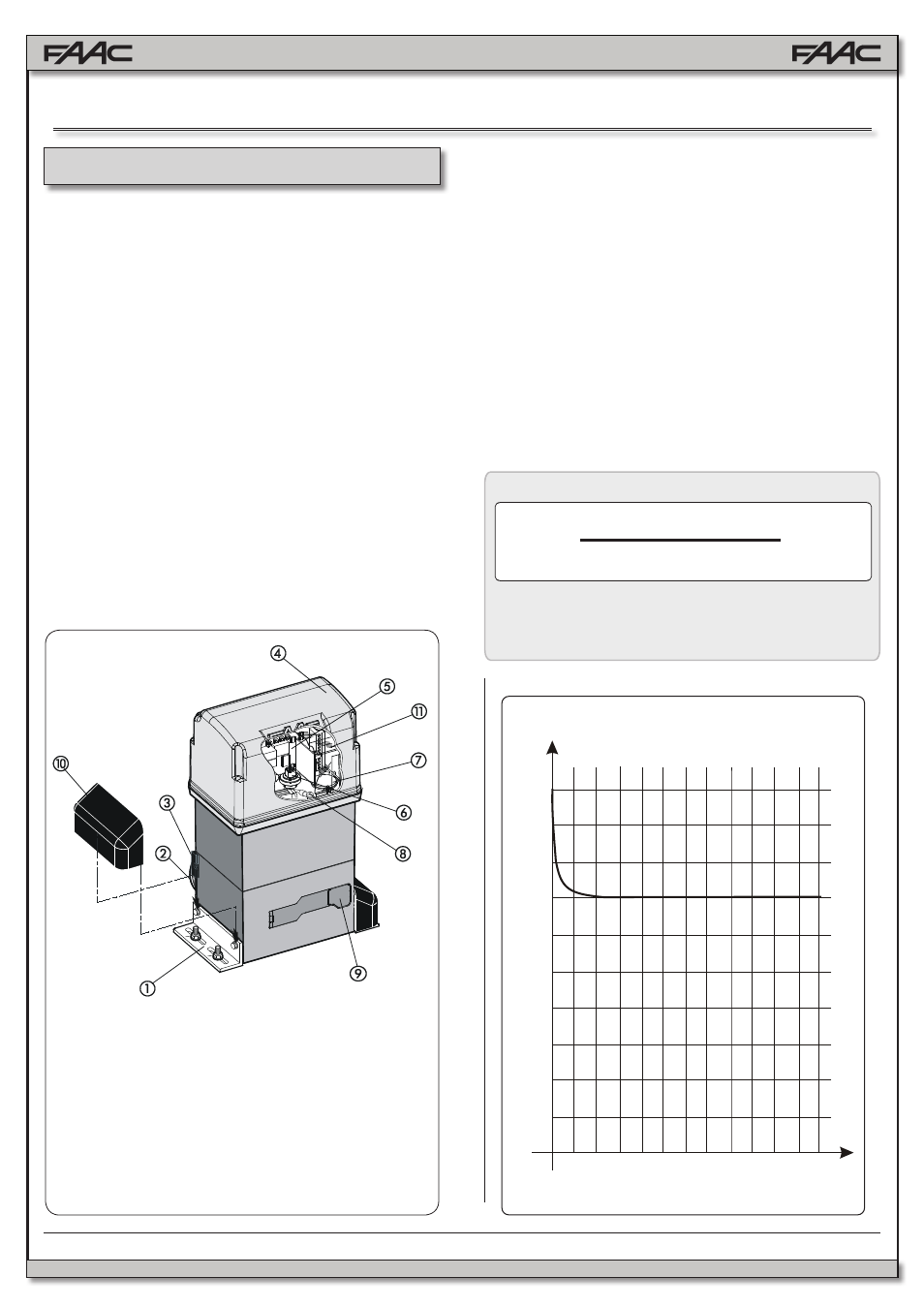

1 Mounting Brackets

2 Pinion

3 Limit Sensor Switch

4 Operator Cover

5 780 D Control Board

6 Adjustment Screw for

Anti-crushing Clutch

7 Oil Filling Plug

8 Operator Grounding

9 Lever Operated Release

System

10 Protective Side Co

11 Cover for 780D Control

Board

Fig. 1

%F =

Ta + Tc

Ta + Tc + Tp + Ti

X 100

Calculation Formula

Where:

Ta = opening time

Tc = closing time

Tp = pause time

Ti = time of interval (between 2 complete cycles)

1.1.

MAXIMUM USE CURVE

The curve makes it possible to establish maximum

work time (T) according to use frequency (F). The

844 gearmotor can operate non-stop at 70% use

frequency.

To ensure efficient operation, operate in the work

range below the curve.

Important: The curve is obtained at a temperature

of 75°F. Exposure to direct sunlight can reduce use

frequency down to 20%.

Calculating Use Frequency

The percentage of effective work time (opening +

closing) compared to total time of cycle (opening +

closing + pause times).

1.

DESCRIPTION & SPECIFICATIONS

0

10

20

30

40

50

60

70

80

90

100

1

2

3

4

5

6

7

8

9 10 11 12

% Freq. Used

% Duty Cycle

Time (h)

Use Frequency Graph