Control board 780d, 780d technical specifications, Layout and components – Controlled Products Systems Group 109837 User Manual

Page 12: Warnings, J1 connector

12

FAAC MODEL 844 Slide Gate Operator

–

+

DL

Led

F1

J1

J2

Led

J5

F

J7

F2

J8

J6

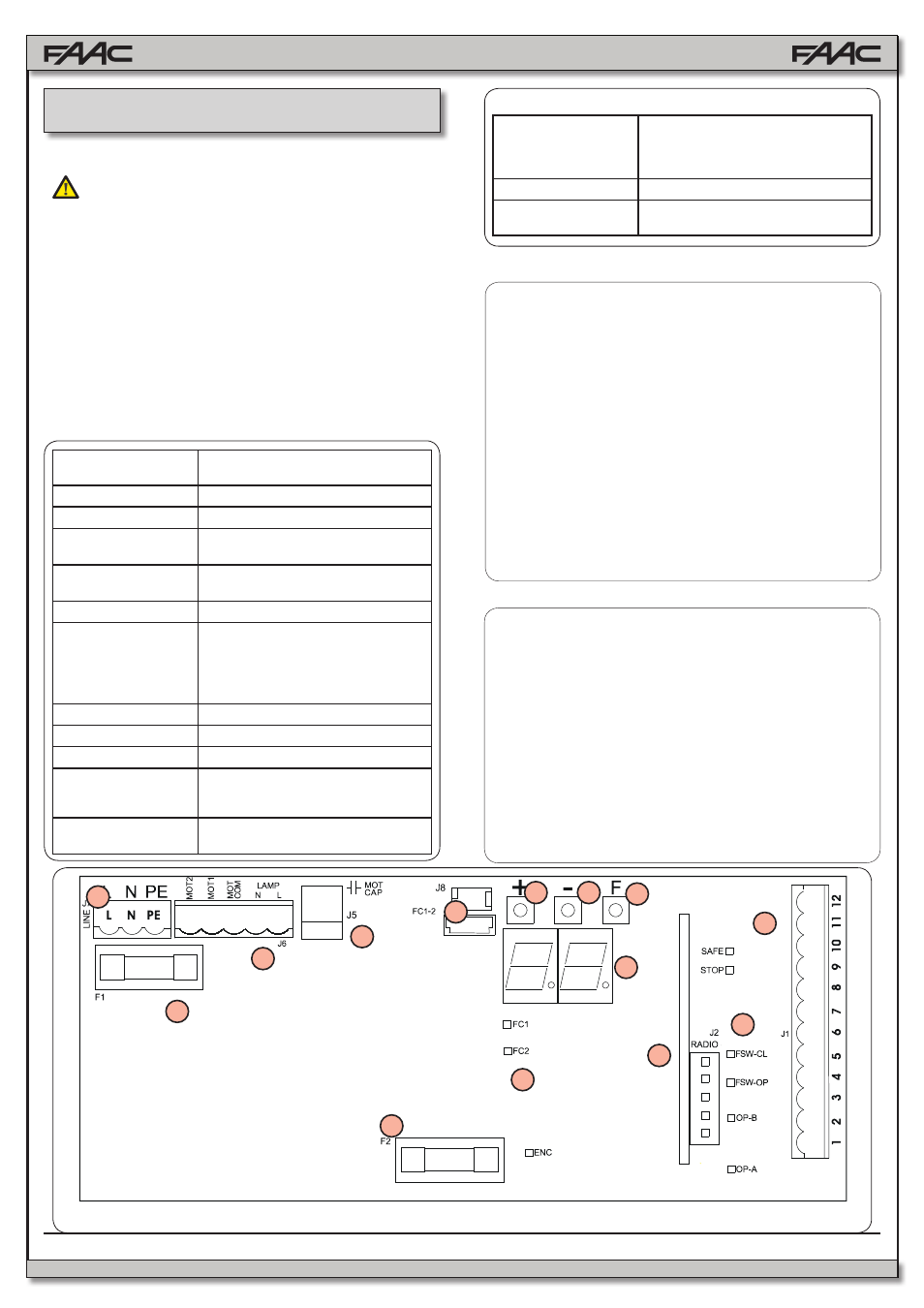

Fig. 22

1

OPEN A (total opening)

2 OPEN B (partial opening)

3

FSW-OP (opening safety devices)

4

FSW-CL (closing safety devices)

5 STOP

6

SAFE (“edge” safety devices)

7

- (negative for power supply to accessories)

8

- (negative for power supply to accessories)

9

+24V (supply to accessories)

10 +24V (supply to accessories)

11 FSW-TX (negative for emitting photocells - FAILSAFE)

12 AA (negative for Audio Alarm)

J1 CONNECTOR

5.2.

780D TECHNICAL SPECIFICATIONS

5. CONTROL BOARD 780D

DL SIGNALLING AND PROGRAMMING DISPLAY

Led INPUTS STATUS CONTROL LED

J1 LOW VOLTAGE TERMINAL BLOCK

J2 CONNECTOR FOR RP RECEIVER

J5 CONNECTOR FOR MOTOR STARTING CAPACITOR

J6 MOTOR AND FLASHING LAMP CONNECTION TERMINAL BLOCK

J7 VAC POWER SUPPLY TERMINAL BLOCK

J8 DOUBLE CONNECTOR - RAPID CONNECTION TO LIMIT-SWITCH

F1 MOTOR AND TRANSFORMER PRIMARY WINDING FUSE (F 5A - 230V;

F 10A - 115V)

F2 LOW VOLTAGE AND ACCESSORIES FUSE (T 800mA)

F

"F" PROGRAMMING PUSH-BUTTON

–

"–" PROGRAMMING PUSH-BUTTON

+

"+" PROGRAMMING PUSH-BUTTON

5.3.

LAYOUT AND COMPONENTS

780D Technical Specifications (continued)

5.1. WARNINGS

Important: Before attempting any work on the control board

(connections, maintenance), always turn off power.

• Check local wiring codes in all cases and follow all local building

codes. Wiring and hookup should be performed by qualified

electricians/installers only.

• AC power should be supplied from a circuit breaker panel and

must have its own dedicated circuit breaker. This supply must

include a green ground conductor.

• Properly ground the gate operator to minimize or prevent damage

from power surges and/or lightning. Use a grounding rod if neces-

sary. Connect the ground cable to the PE terminal on J7 (Fig. 22),

and to the ground lug on the operator (Fig. 40). A surge suppres-

sor is recommended for additional protection.

• Always separate power cables from control and safety cables

(push-button, receiver, photocells, etc.).

Power Supply V~

(+6% -10%)

115 or 230

Absorbed Power (W)

10

Motor Max. Load (W)

1000

Accessories Max.

Load (A)

0.5

Operating Ambient

Temperature

-4°F to +131°F

Protection Fuses

2 (see Fig. 22 and Section 5.3)

Function Logics

Automatic / “Stepped” automatic /

Semi-automatic / Safety devices /

Semi-automatic B / Dead-man C /

“Stepped” semi-automatic / Mixed B/C

logic

Work Time

Programmable (from 0 to 4.1 min.)

Pause Time

Programmable (from 0 to 4.1 min.)

Thrust Force

Adjustable over 50 levels

Terminal Board

Inputs

Open - Partial Open - Opening safety

devices - Closing safety devices - Stop

- Edge - Power supply+ground

On-Connector Inputs

Opening and closing limit-switch -

Motor capacitor

Terminal Board

Outputs

Flashing lamp - Motor - 24 VDC

accessories power supply- 24 VDC

indicator-light / Timed output / Electric

lock command - 'traffic lights' - Failsafe

Rapid Connector

5-pin card connection for RP receivers

Programming

3 keys (+, -, F) and display, "basic" or

"advanced" mode