Controlled Products Systems Group 1044182 User Manual

Page 8

Pag e 8

M a y, 20 06

4 1 5 L LS Ope ra tor And

4 5 5 D C ontrol Pa ne l I nsta ll a ti on Ma nua l

A

TTACH

THE

R

EAR

M

OUNTING

B

RACKET

Inward swinging gate:

You need to determine whether to attach the rear

mounting bracket directly to the post (or wall) or to

notch the post and install a recessed liner. Large pillars

require a recessed liner to house the rear mounting

bracket and part of the operator so that the pillar will

not interfere with the swing of the gate when it is fully

opened.

To determine whether you need a recessed liner,

measure the distances B and D (shown in Fig. 9) on your

gate. If your measure of B or D is greater than the

dimensions shown for your operator in Figure 9, notch

the post and construct a recessed liner for the post

mounting bracket (see Figure 7). The recessed liner

should be constructed of 3/16 or 1/4 in. steel with a

minimum interior height of 8in. (20.32 cm) so as to

allow you to meet the required dimensions shown in

Figure 9. Make sure the recessed liner is securely

embedded in the post (or wall).

There are two parts to the rear mounting bracket. The

horizontal bracket attaches to the operator, and the

drilled plate that can be bolted to the gate post. Weld

the two parts together and bolt the assembly to the gate

post or column. Note, though, that use of the vertical

rear mounting plate is optional.

Once you have positioned the rear mounting bracket,

attach the bracket to the post (or wall or recessed liner),

making sure the dimensions on your gate system match

those shown in Figure 9.

Outward swinging gate:

If you are installing the 415 L LS Operator to swing the

gate outward, construct a steel elbow of sufficient size

to attach to the gate pillar and rear mounting bracket

(see Figure 10 for elbow dimensions).

A

TTACH

THE

F

RONT

M

OUNTING

B

RACKET

TO

THE

G

ATE

L

EAF

Disengage the operator’s manual release (see figure 2).

You should be able to lengthen or shorten the cylinder

by pulling or pushing the cylinder. Lengthen or shorten

the operator to the required distance for your gate

installation:

Inward swinging: Lengthen the piston rod until

the appropriate limit led (FCC or FCA) goes

out on the control panel.

Outward swinging: Shorten the piston rod until

the appropriate limit led (FCC or FCA) goes

out on the control panel.

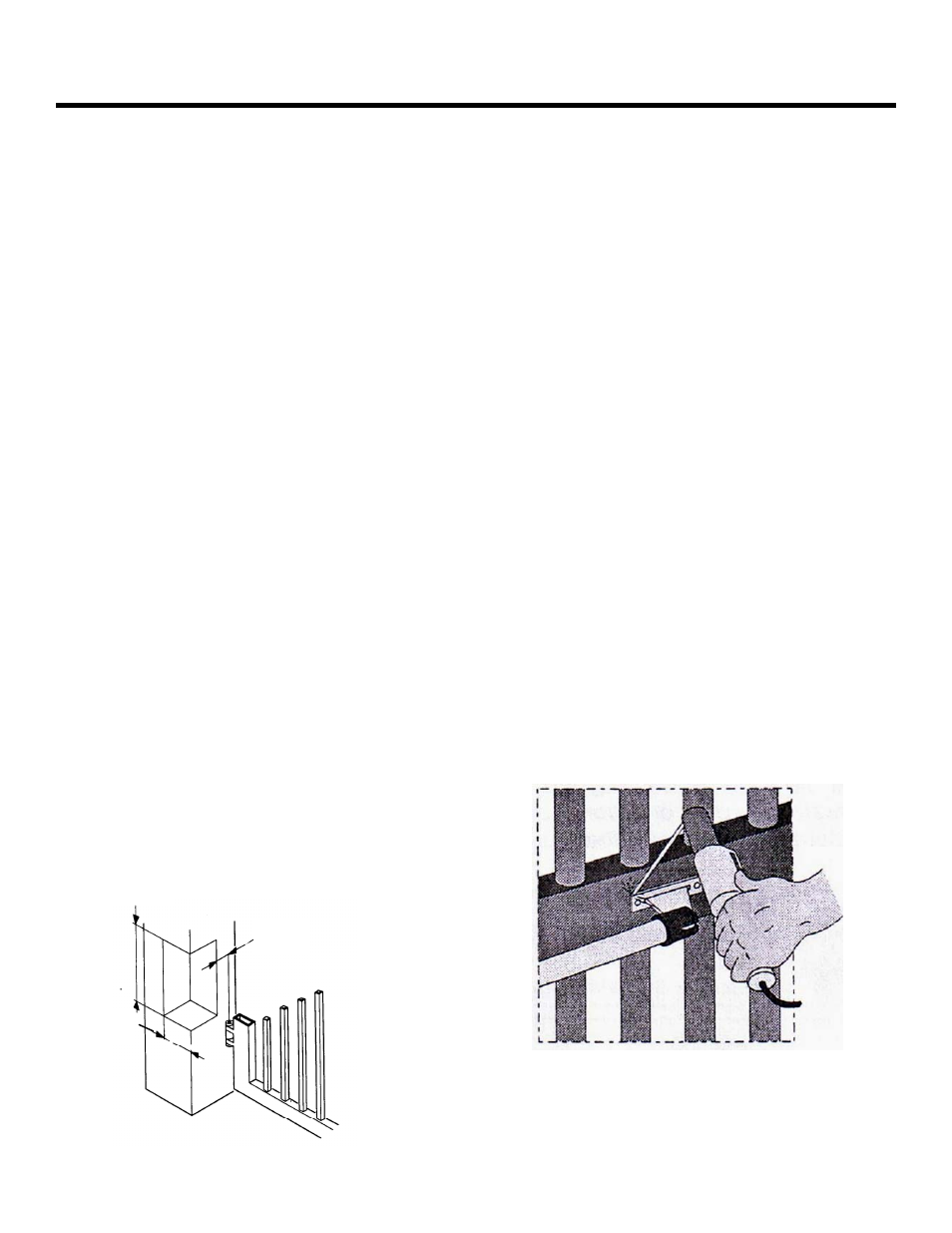

With the gate in the fully closed position, temporarily

clamp the front mounting bracket (previously attached

to the operator) to the gate leaf and insure that the

cylinder is level.

Manually open the gate to ensure full swing of the

operator.

Remove the operator from the front mounting bracket

for welding.

With the operator detached from the front mounting

bracket, permanently attach (weld or bolt) the front

mounting bracket to the gate leaf (see Figure 8).

Once the front mounting bracket is welded or bolted in

place, you can reattach the operator to the bracket.

11 13/16 in.

(30 cm)

4 in.

(10 cm)

5 29/32 in.

(15 cm)

Figure 7. The

required dimensions

of the recessed liner

when notching the

gate post

Figure 8. Weld the front mounting bracket into position

after insuring the operator is level.

8 in

(15.24 cm)

10 in

(25.40 cm)