Tuning, Tuning -27 – CONTREX ML-TRIM User Manual

Page 61

3 - 27

Tuning

If your system is unstable, or the speed error is unacceptable, tuning stabilizes speed

error differences between the setpoint and feedback. You can achieve a stable system

using conservative tuning Control Parameter values, however the speed error may be

unacceptable. On the other hand, aggressive tuning Control Parameter values may

cause the system to become unstable. The goal is to reduce the speed error to the

level that you want, yet maintain the system's stability.

To achieve an acceptable level of speed error, adjust the Gain (CP-65) until the system

stabilizes. In systems that require greater accuracy, it may be necessary to adjust the

Integral (CP-66) to reduce any remaining speed error. In systems with low inertia, the

speed error will be reduced more quickly if you enter low values in CP-66. An entry that

is too low, however, can create instability or overshoot the setpoint before reaching the

correct value. Generally, use larger entries for CP-66 on systems with a large inertia.

Sometimes performance can be improved in systems with a large inertia by lowering

the Derivative (CP-67).

The ML–Trim comes factory pre-loaded with default Control Parameters for Tuning.

These default settings are suitable for most applications and do not require

modification. The factory preset, default tuning Control Parameters are found in Table

3-21. To modify these default parameters, refer to Table 3-22. If you are uncertain how

to enter a Control Parameter, review the

Operations: Keypad

section, page 3-3.

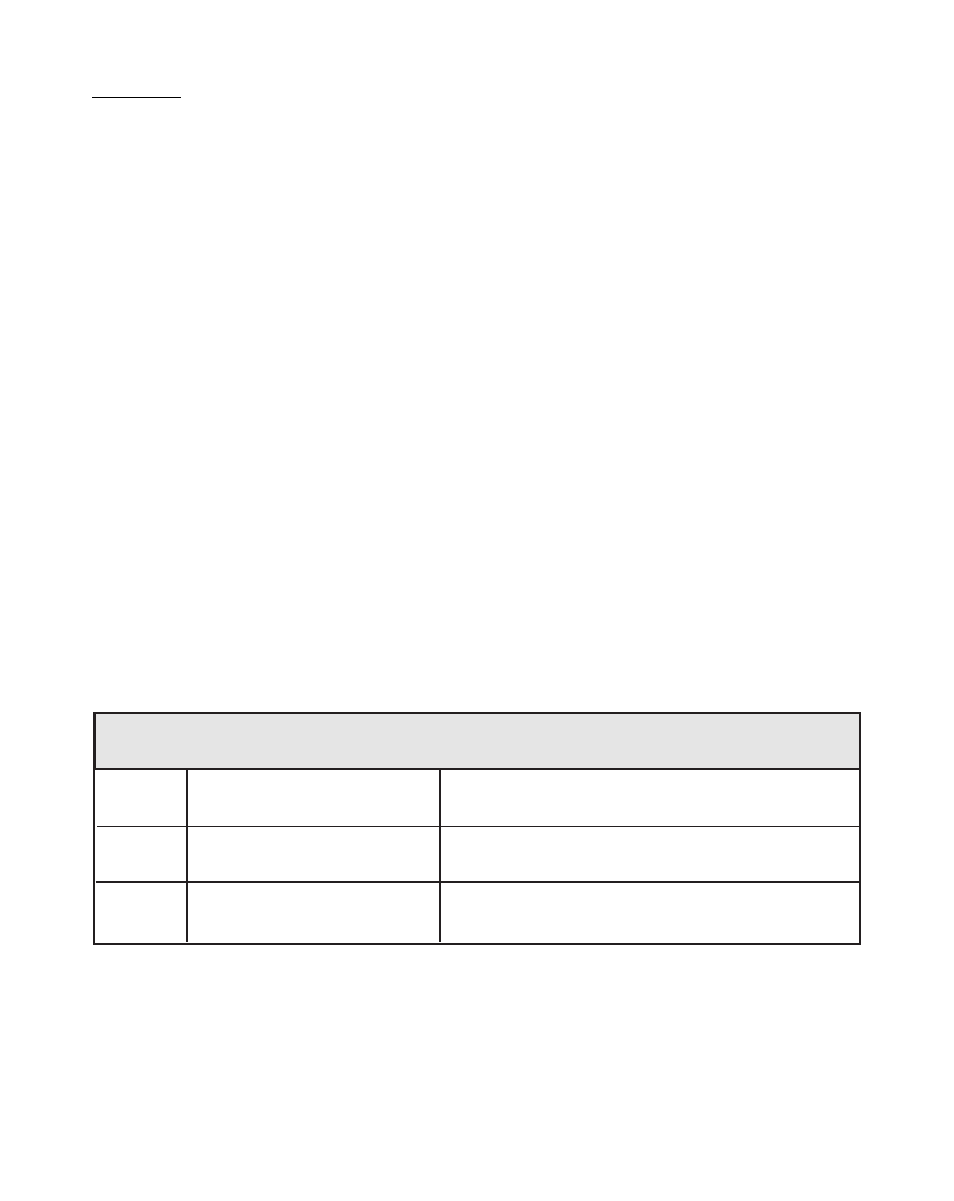

Table 3-21 Default Master or Follower Tuning Control Parameters

CP

Parameter Name

Parameter Value

CP-65

Gain (Proportional)

9000

CP-66

Integral

2000

CP-67

Derivative

9000