Cashco DA6 User Manual

Page 6

IOM-DA6

6

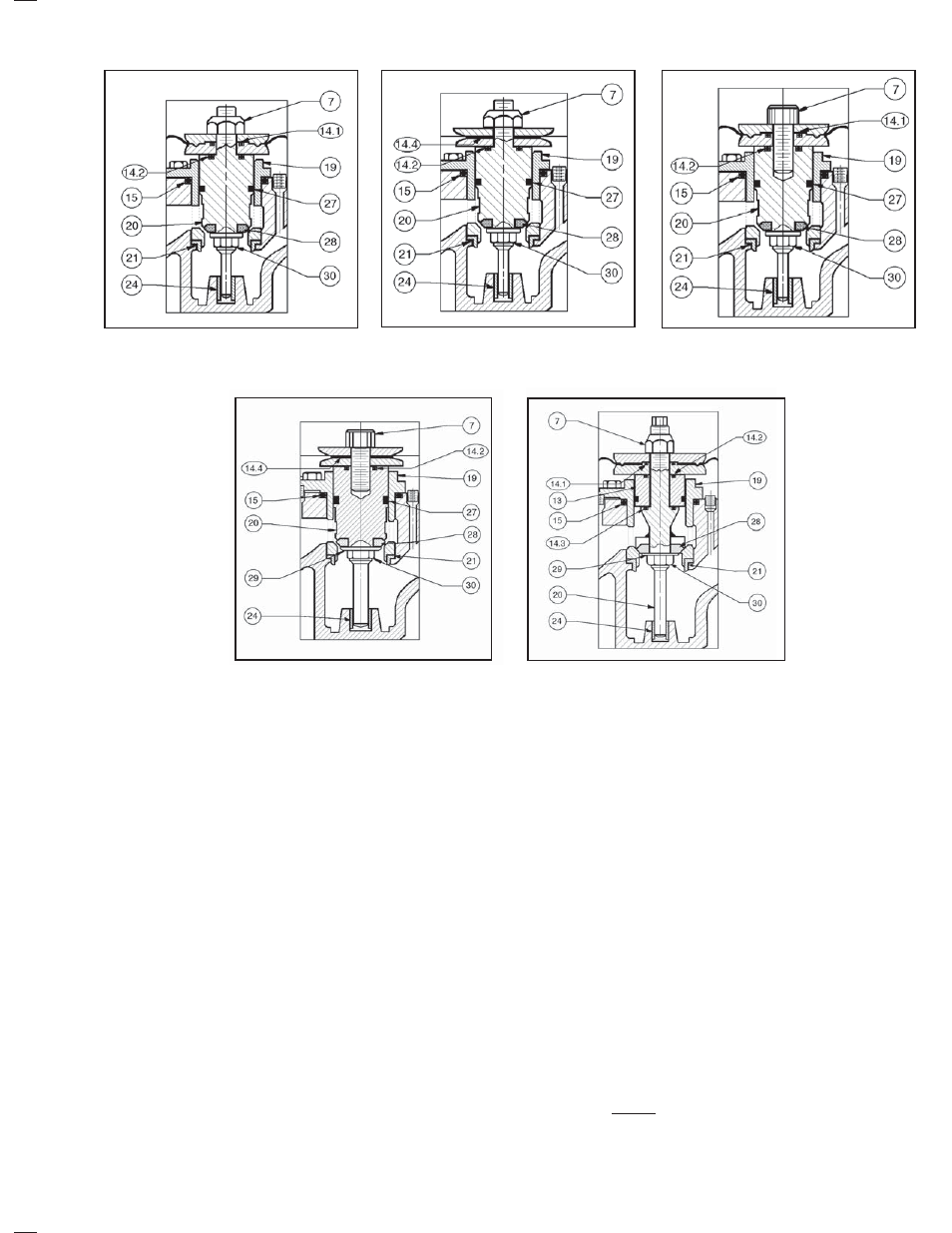

Figure 2: Body Sizes

1/2" – 1", Composition Di a phragm

Figure 3: Body Sizes

1/2" – 1", Metal Diaphragm

Figure 4: Body Sizes

1-1/4" – 2", Composition Diaphragm

Figure 5: Body Sizes

1-1/4" – 2", Metal Diaphragm

con di tions are ex ceed ing pressure drop

or temperature limits.

e. Remove

up

per stem seal (14.1).

f. Remove lower diaphragm push er plate

(10).

g. Remove middle stem seal (14.2).

h. Remove piston/guide bearing (13) with

dynamic side seal (27) in place.

i. Remove lower stem seal (14.3).

j. Place socket wrench on upper end of plug

(20) as in Step b. above. Ro tate plug (20)

CCW (viewed from above) to loosen seat

disc nut (30). Once nut (30) is loos ened,

re move partial as sem bly (20, 27, 28, 29,

30) from vise. Complete re mov al of seat

disc nut (30), seat disc washer (29) and

seat disc (28).

3. Examine the components (27.1, 27.2, 27.3,

27.4, 27.5, 27.6) of the dynamic side seal

(27) to determine if sig nifi cant leak age was

oc cur ring. If the dynamic side seal (27) shows

signs of signifi cant leakage, de ter mine if op-

er at ing conditions are ex ceed ing pres sure,

pres sure drop, or temperature lim its.

Remove dynamic side seal (27) components

from plug (20) for sizes 1/2" – 2", or from pis-

ton/guide bearing (13) for sizes 2-1/2" – 4".

Special care should be tak en when using

“tools” to remove the com po nents to ensure

that no scratches are im part ed to any portion

of the plug (20) or piston/guide bearing (13)

groove.

4. Solvent clean all metal parts to be reused.

D. Inspection of Parts:

1. After inspection, remove from the work area

and dis card the old “soft goods” parts (i.e.

o-rings, di a phragms, seals, etc.). Metal di-

a phragms should be replaced. These parts

MUST be re placed with fac to ry supplied new

parts.

Figure 6: Body Sizes

2-1/2" – 4", Composition Di a phragm