Cashco DA6 User Manual

Page 12

IOM-DA6

12

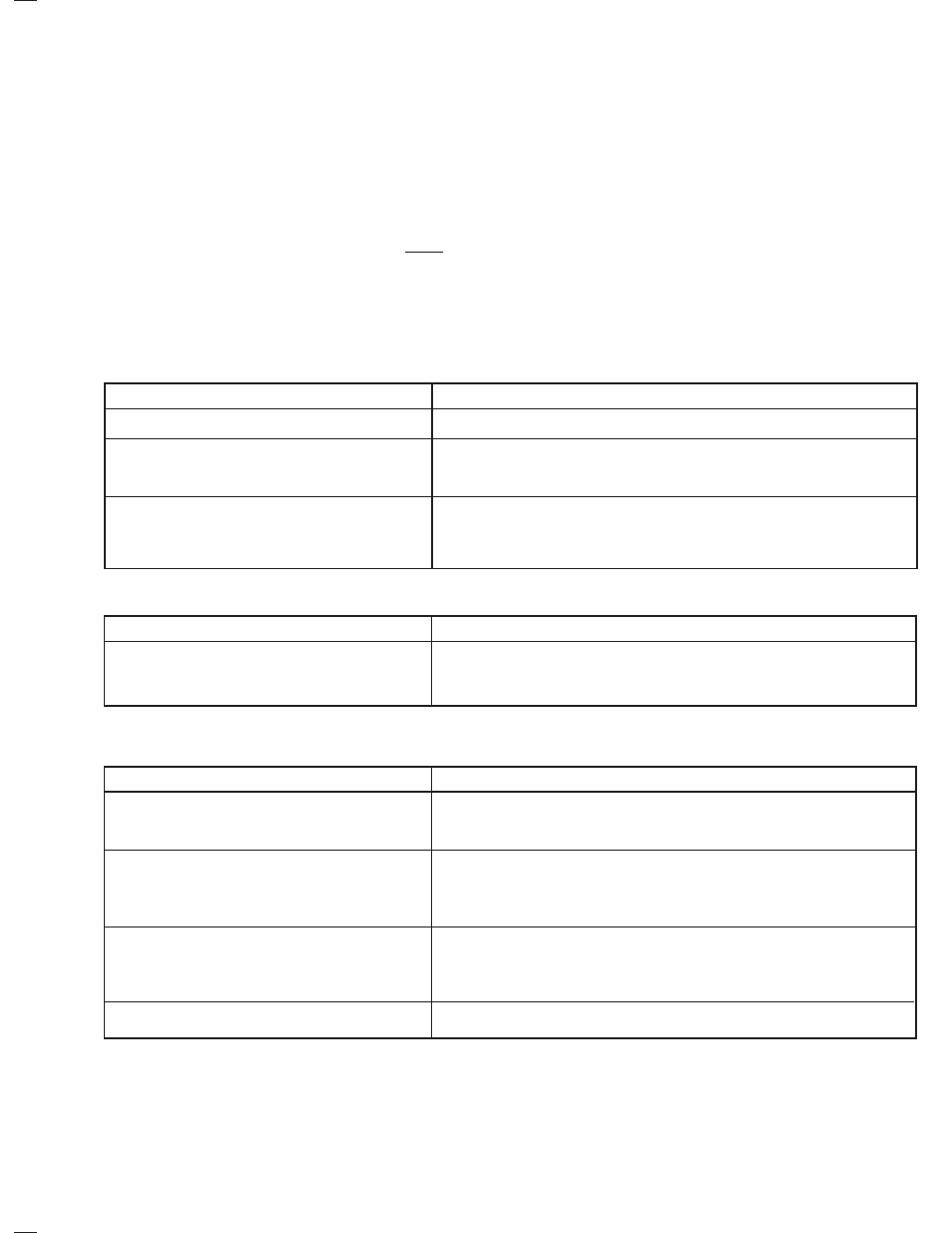

1. Erratic regulation, instability or hunting.

Possible Causes

Remedies

A. Sticking of internal parts

A. Remove internals, clean, and if necessary, replace.

B. Load changes are too quick for

B. Convert to external sensing (if necessary) and install

system

an

orifi ce or needle valve in external sensing line.

C. Oversized regulator

C. Check actual fl ow conditions; resize regulator for min i mum

and

maximum

fl ow; if necessary, replace with smaller

regulator.

2. Erratic regulation, instability or hunting (liquid service).

Possible Causes

Remedies

A. Air trapped under diaphragm

A. Install valve on external sensing port and bleed off air.

(Install regulator upside down to help prevent re oc cur rence.)

3. Upstream pressure too high.

Possible Causes

Remedies

A. Supply pressure is down (confi rm

A. Increase supply pressure.

on pressure gauge).

B. Undersized regulator.

B. Check actual fl ow conditions; resize regulator for min i mum

and

maximum

fl ow; if necessary, replace with larger

regulator.

C. Pressure loading system pressure

C1. Clean restriction or bleed orifi ces.

restricted.

C2.

Clean

fi lter(s).

C3. Clean loading pressure control device.

D. Faulty loading pressure control device.

D. Replace/repair loading pressure control device.

It is imperative the following information be provided by the customer:

• Fluid (with fl uid properties)

• Range of fl ow rate

• Range of inlet pressure

• Range of outlet pressure

• Range of fl uid temperature

• Range of ambient temperature

Pressure readings should be taken at every location that pressure plays a role - i.e., regulator inlet (as close as

possible to inlet port), regulator outlet (as close as possible to outlet port), etc.

Following are some of the more common com plaints along with possible causes and remedies.