Operation, Factory default jumper configuration, Configuration jumpers – Fluid Components International FLT93 Nuclear User Manual

Page 19: Heater cut-off, 3 operation

FLT

®

Series FlexSwitch

TM

OPERATION

Fluid Components International LLC

19

3 OPERATION

Caution:

The control circuit contains electrostatic discharge (ESD) sensitive devices. Use standard ESD precautions when handling

the control circuit. See Chapter 2, Operation, for ESD details.

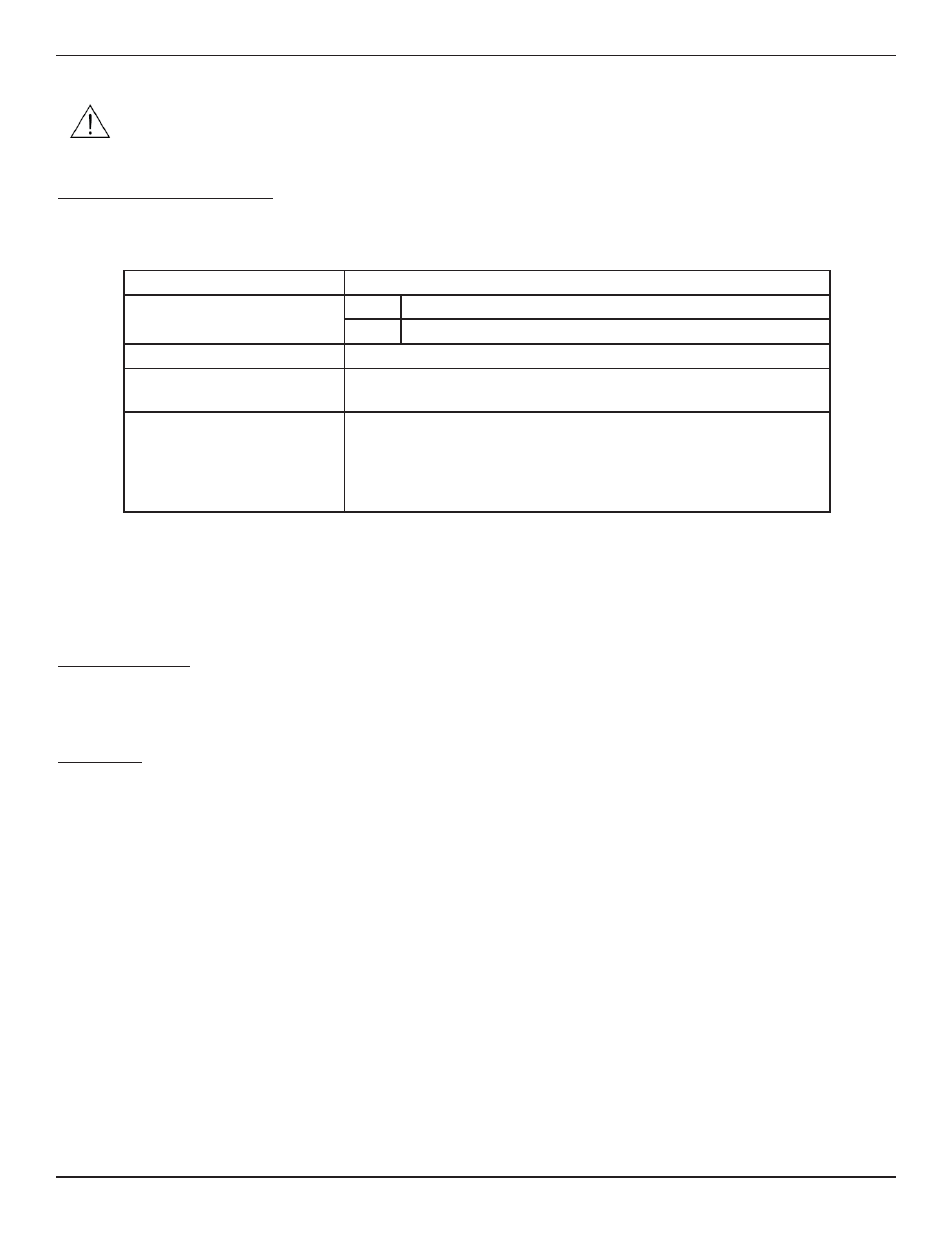

Factory Default Jumper Confi guration

Unless a custom factory setup or calibration is specifi ed, the instrument is delivered in a standard factory confi guration. The standard default

jumper confi guration is shown in Table 3-1.

Input Power

Factory Confi gured

Heater Power

FLT93-S 0.75 watts for air or liquid level applications. (J13)

FLT93-F 0.25 watts for air or liquid level applications. (J14)

Number of Alarms

Two (J23). Each alarm has one set of SPDT contacts

Alarm No. 1 Red LED

Set Point Pot, R26

Set to monitor fl ow or level signals (J20). Relay energized at fl ow or wet (J27)

Alarm No. 2 Green LED

Set Point Pot, R25

Set to monitor temperature signals (J19). Relay energized below temperature (J25).

Set point at approximately:

250 F (121 C) for standard temperature,

500 F (260 C) for medium temperature,

850 F (454 C) for high temperature (FLT93-S Only)

Table 3-1 Standard Jumper Defaul Confi guration

If the order included custom factory setup and calibration, leave all settings alone. The instrument is ready for service without changes.

If custom factory setup or calibration was not ordered, confi gure the control circuit using the jumper tables (Tables 3-2 to 3-6) and then fol-

low the set point adjustment section that is appropriate for the application.

Confi guration Jumpers

If the order did not specify for the control circuit to be factory confi gured, the standard confi guration can be changed using Figure 3-1 and

Table 3-2 though Table 3-6. The factory default confi guration is shown as being underlined.

Heater Cut-Off

The 5298 control circuit has a heater cutoff switch that limits the skin temperature of the sensing element to a temperature differential of

approximately 150°F (66°C) above the process temperature. In the case where the instrument is used as a gas fl ow switch, and the heater

wattage is set too high, the temperature differential (DT) between the RTDs may exceed the usable input range of the control circuit. The us-

able input range can also be exceeded in the case where the instrument is used in liquid fl ow applications where the heater wattage is set at

the highest value, and when the sensing elements go dry. When the temperature differential is less than 150°F (66°C) the heater automati-

cally turns back on. The yellow power indicator LED (DS3) turns on and off with the heater for a visual indication of the heater state. The

LED will alternate between on and off until the condition is corrected.

The reason for operating in the above extreme conditions is that the input signal range is at the widest point making the alarm set point

adjustment easier to perform. If the heater does cycle the operator may need to use the next lower wattage setting.

In some applications it is desirable to set the heater wattage high, even though the sensing element goes into the heater cutoff mode. An

example is when the instrument is used to detect the interface of two liquids. These liquids may have viscosities that will have signals very

close to each other. In order to have the maximum signal difference between the signals the heater wattage is set to its maximum. If the

sensing element detects a dry condition the control circuit will indicate a heater cutoff condition. The sensing element will not be dammaged

if it is left dry with the maximum heater wattage. The alarms can be set so one alarm will switch at the interface and one alarm can detect

when the element goes dry.