8 pneumaic installation, 8pneumatic installation – Burkert Type 8695 User Manual

Page 14

14

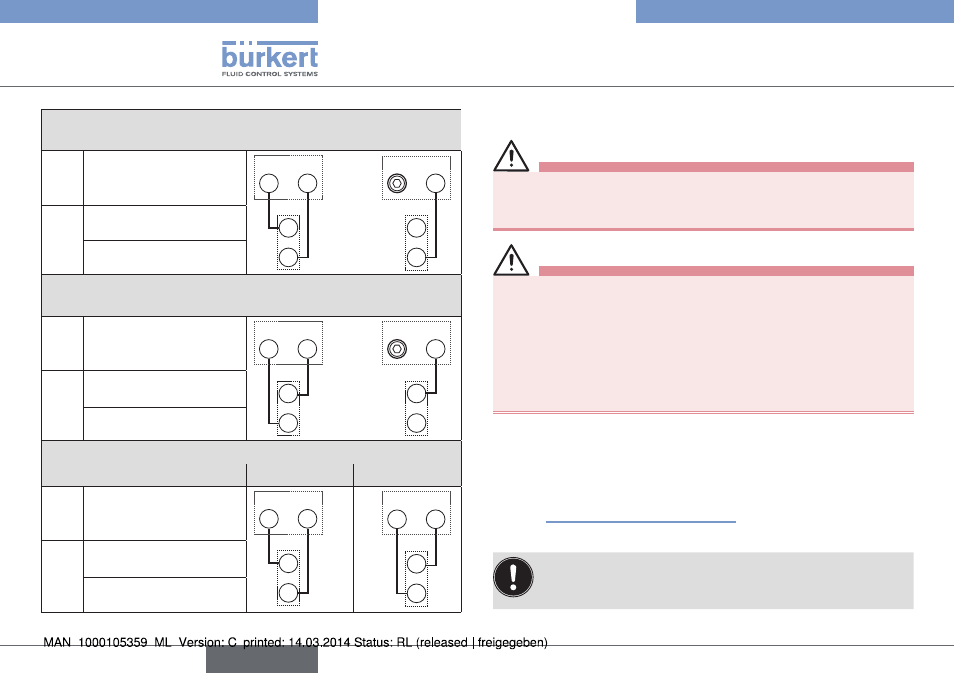

Pneumaticinstallation

control function a (cfa)

Process valve closed in rest position (by spring force)

Control

head

Pilot air outlet

2

2

2

1

or

2

2

2

1

Actuator

Upper pilot air port

Lower pilot air port

control function B (cfB)

Process valve open in rest position (by spring force)

Control

head

Pilot air outlet

2

2

2

1

or

2

2

2

1

Actuator

Upper pilot air port

Lower pilot air port

control function i (cfi)

Process valve in rest position

closed

open

Control

head

Pilot air outlet

2

2

2

1

2

2

2

1

Actuator

Upper pilot air port

Lower pilot air port

Tab. 1: Pneumatic connection to actuator

8

pneumaTic insTallaTion

Danger!

risk of injury from high pressure in the equipment/device.

▶ Before working on equipment or device, switch off the pressure

and deaerate/drain lines.

Warning!

risk of injury from improper installation.

▶ Installation may be carried out by authorized technicians only

and with the appropriate tools.

risk of injury from unintentional activation of the system and

an uncontrolled restart.

▶ Secure system from unintentional activation.

▶ Following installation, ensure a controlled restart.

procedure:

→

Connect the control medium to the pilot air port (1)

(3 – 7 bar; instrument air, free of oil, water and dust).

→

Attach the exhaust airline or a silencer to the exhaust air port (3)

(see “Fig. 8: Pneumatic connection”).

Keep the adjacent supply pressure always at least 0.5 –

1 bar above the pressure which is required to move the

actuator to its end position.

english

Type 8695