Burkert Type 8695 User Manual

Page 13

13

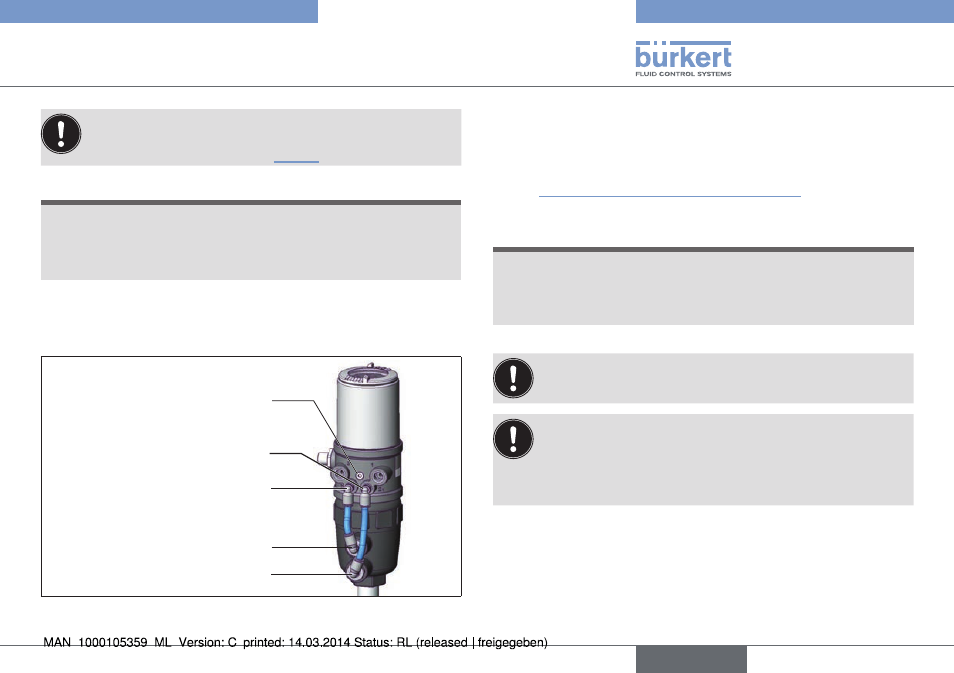

Installation

Ensure that the pneumatic connections of the control head

and those of the valve actuator are situated preferably verti-

cally one above the other (see “Fig. 7”).

note!

too high torque when screwing in the fastening screw does

not ensure protection class ip65 / ip67.

▶ The fastening screws may be tightened to a maximum torque of

0.5 Nm only.

→

Attach the control head to the actuator using the two side fas-

tening screws. In doing so, tighten the fastening screws hand-

tight only (maximum torque: 0.5 Nm).

Pilot air outlet 2

1

Pilot air outlet 2

2

Upper pilot air port

Lower pilot air port

Fastening screws (2x)

Fig. 7:

Installing the pneumatic connection, 20xx series

→

Screw the plug-in hose connectors onto the control head and

the actuator.

→

Using the hoses supplied in the accessory kit, make the pneu-

matic connection between the control head and actuator with

the “Tab. 1: Pneumatic connection to actuator”.

note!

damage or malfunction due to ingress of dirt and moisture.

▶ To comply with protection class IP65 / IP67, connect the pilot

air outlet

(only for CFA or CFB) which is not required to the free

pilot air port of the actuator or seal with a plug.

“In rest position” means that the pilot valves of the control

head Type 8695 are isolated or not actuated.

If the ambient air is humid, a hose can be connected between

pilot air outlet 2

2

of the control head and the unconnected

pilot air port of the actuator for control function A or control

function B. As a result, the spring chamber of the actuator is

supplied with dry air from the vent duct of the control head.

english

Type 8695