Burkert Type 8690 User Manual

Page 17

17

Installation

noTE!

screw locking paint may contaminate the groove ring!

• Do not apply any screw locking paint to the switch spindle.

→

To secure the switch spindle, apply some screw locking paint

(Loctite 290) in the tapped bore of the spindle extension in the

actuator.

→

Check that the O-ring is correctly positioned.

→

Screw the central screw to the actuator cover (maximum torque:

5 Nm).

→

Screw switch spindle onto the spindle extension. To do this,

there is a slot on the upper side

(maximum torque: 1 Nm).

→

Position the switch cam on the switch spindle so that the dis-

tance between the switch cam and top of the spindle is 10 mm

(see “Fig. 7”)

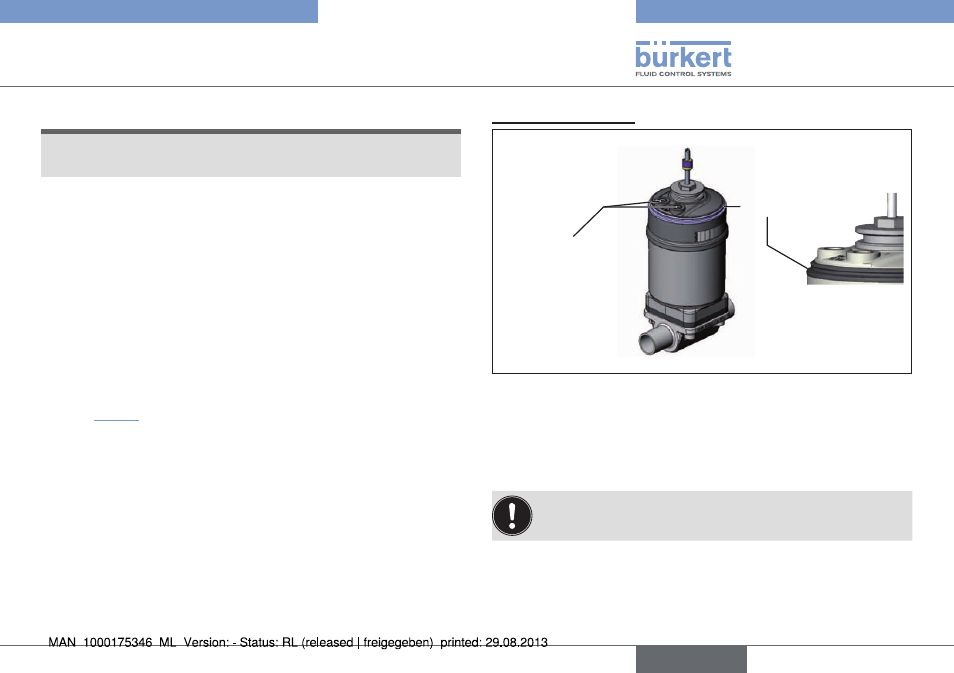

2. install sealing rings

Form seal

Pilot air ports

Caution:

Collets must not be

fitted !

Installation of

the form seal

Fig. 8: Installing of the sealing rings, 21xx series

→

Pull the form seal onto the actuator cover (smaller diameter

points upwards).

→

Check that the O-rings are correctly positioned in the control air

connections.

When the Pneumatic Control Unit is being installed, the collets

of the pilot air ports must not be fitted to the actuator.

english

Type 8690 Ex