Burkert Type 6212 User Manual

Page 6

20

mainTenance,

8.

TrOubleshOOTing

safety instructions

8.1.

Danger!

Risk of injury from high pressure in the equipment!

Before loosening the pipes and valves, turn off the

•

pressure and vent the pipes.

Risk of injury due to electrical shock!

Before reaching into the device or the equipment,

•

switch

off the power supply and secure to prevent reactivation!

Observe applicable accident prevention and safety

•

regulations for electrical equipment!

Warning!

Risk of injury from improper maintenance!

Maintenance may be carried out by authorized techni-

•

cians only and with the appropriate tools!

Risk of injury from unintentional activation of the

system and an uncontrolled restart!

Secure system from unintentional activation.

•

Following maintenance, ensure a controlled restart.

•

english

21

installation of pilot valve

8.2.

Warning!

Escaping medium!

When a sticking screw is loosened, medium may escape.

Do not tighten sticking screws any further.

•

Electric shock!

If the protective conductor is not connected, there is a

risk of electric shock!

Check protective conductor contact after installing the

•

coil

note!

If the tightening torque is too great, the device may

be damaged!

Observe the maximum tightening torque of the screws!

•

Device will be damaged if the wrong tools are used!

Always use a right tools to tighten screws. If other

•

tools are used (e.g. pliers), the device may be

damaged.

english

22

0.3 ± 0.05 Nm

0.2 ± 0.05 Nm

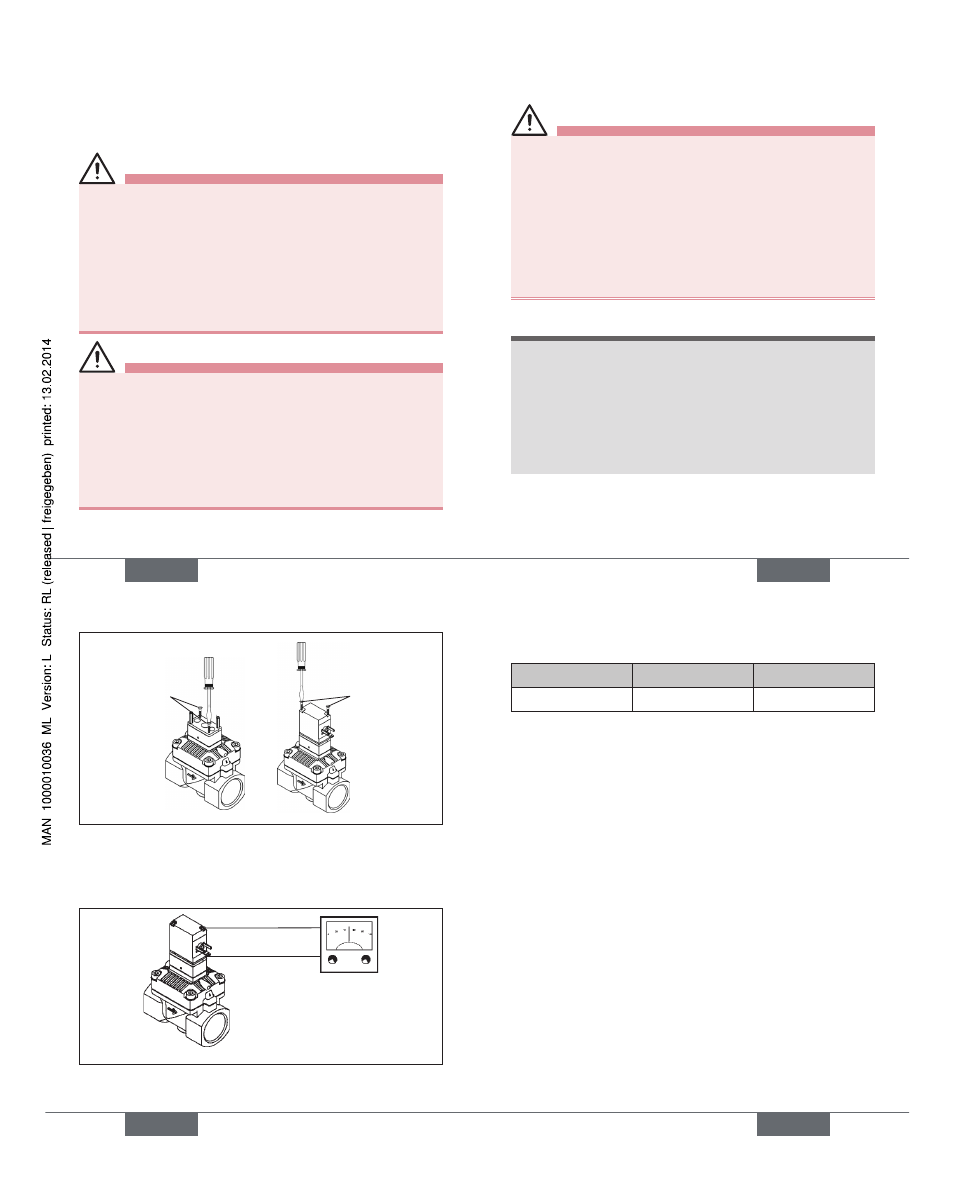

Installation of pilot valve

Fig. 4:

Attach pilot valve to Armature:

→

Tighten the screws with 0.2 ± 0.05 Nm.

Protective conductor function

Fig. 5:

english

23

Check functionality of the protective conductor

→

Resistance

Test voltage

Test current

max. 0,1 Ω

12 V

1 A

malfunctions

8.3.

If malfunctions occur, check whether:

the device has been installed according to the

→

instructions,

the electrical and fluid connections are correct,

→

the device is not damaged,

→

all screws have been tightened,

→

the voltage and pressure have been switched on,

→

the pipelines are clean.

→

Valve does not switch

Possible cause:

Short-circuit or coil interrupted,

•

Internal space of the valve is dirty,

•

Medium pressure outside the permitted pressure range.

•

english

Type 6212