Burkert Type 2036 User Manual

Page 29

29

Repairs

Type 2036

12.2.2. assembly of actuator and

diaphragm

Warning!

risk of injury from moving parts in the device.

• When applying or removing the pilot pressure on the actuator,

keep limbs and objects away from the openings of the actuator.

→

Move the actuator to the lower actuator position (CFA, NC: by

removing pilot pressure; CFB, NO: by applying the pilot pressure).

→

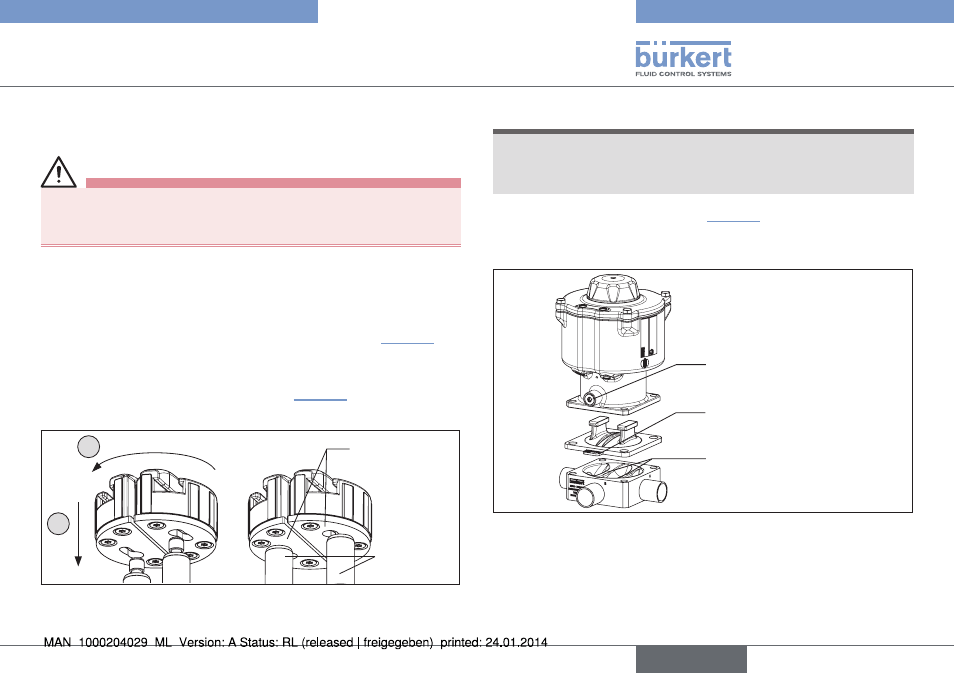

Insert the diaphragm into the guide of the pressure pieces. Make

sure that the four spacing sleeves are installed (see "Fig. 20").

→

Insert the pressure pieces into the actuator. Make sure that

the actuator spindles are fully inserted into the corresponding

recesses of the pressure pieces (see "Fig. 21").

→

Turn the diaphragm and pressure pieces through approx. 30°.

approx. 30°

2

1

Pressure

pieces

Actuator

spindle

Fig. 21: Assembly pressure pieces

note!

damage to the diaphragm.

• Turn diaphragm and pressure pieces only as far as is required

until the actuator and diaphragm screw holes are in alignment.

→

Screw guide pin all the way in ("Fig. 19").

→

Move the actuator to the upper actuator position (CFA, NC: by

applying pilot pressure; CFB, NO: by removing the pilot pressure).

Body seat

Identification plate

diaphragm

Guide pin

Fig. 22: Assembly of the actuator

→

Put the actuator / diaphragm on the body with correct alignment

(so that the markings made previously align, or guide pin, identifi-

cation plate and body seats have been aligned in parallel). In the

case of RV110 the four spacer sleeves must be inserted in the

designated body holes.

english