Burkert Type 2036 User Manual

Page 18

18

TechnicalData

Type 2036

Connections

Port connections

welded spigots

DIN EN ISO 1127 / ISO 4200) /

DIN 11866 Series 2,

DIN 11850 Series 2 / DIN 11866 Series A

ASME BPE / DIN 11866 Series C

Clamp

DIN 32676 Series A (DIN pipe)

DIN 32676 Series B (ISO pipe)

ASME BPE

(other connections on request)

Pilot air port

G1/8

Surface quality

interior

Ra 0.6 µm passivated

exterior

Ra 1.6 µm machined

optional electro-polished

(other surface finishes on request)

Installation position

any position; preferably connection B

downwards; for self-drainage see chapter

"5.4. Valve self-draining"

The service life of the device depends heavily on the conditions of use.

Especially the service life of the diaphragm depends very heavily on

the conditions of use, such as the medium, temperatures, switching

frequency, pressure etc., and may vary widely in individual cases.

7.6.1. Diaphragm

The diaphragm seals the valve. It must be selected with care. The

choice of material should be made bearing in mind the process

medium, the temperature and the mechanical boundary conditions

(e.g. operating pressure, switching frequency etc.).

The standard materials are contained in the following table.

For conformity with FDA CFR 21 Para. 177.2600 or Para. 177.1550

and USP VI certification, see "Tab. 1: Diaphragm materials".

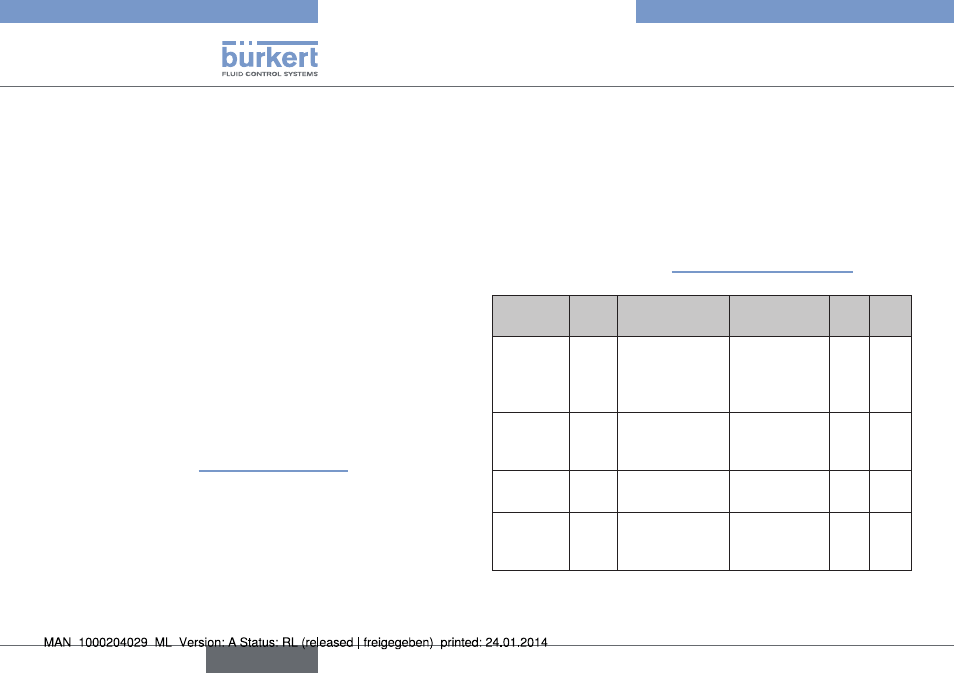

Diaphragm

material

Code Description of

material

Use

FDA USP

VI

EPDM

AD

Peroxide-vulca-

nized ethylene-

propylene

rubber

Oxidizing

chemicals,

steam and hot

water

x

x

Advanced

PTFE /

EPDM

EK

Advanced PTFE

laminated

EPDM

Most chem-

icals and

acids

x

x

FKM

KL

Fluorinated

rubber

Acids and

mineral oils

x

Silicone

SK

Platinum-sta-

bilized silicone

rubber

Aliphatic oils

x

x

Tab. 1: Diaphragm materials

english