Burkert Type 2037 User Manual

Page 12

12

Assembly

mount actuator and diaphragm on the body:

→

After welding in the body, smooth the body surface by grinding if

required.

→

Carefully clean the body.

procedure for control function a

→

Pressurize the lower control air connection with compressed air

(value on type label) (see „Fig. 7: Control air connection“).

→

Place actuator on the body.

→

Gently tighten the body screws in diagonal pairs until the dia-

phragm lies between the body and actuator.

do not fully tighten screws yet.

→

Actuate the diaphragm valve twice to position the diaphragm

correctly.

→

Without applying pressure, tighten the body screws to the permitted

tightening torque (see „Tab. 2: Tightening torques for diaphragms“).

→

Pressurize the lower control air connection with compressed air

(value on type label).

→

Check the tightening torque of the screws again.

procedure for actuator with control functions b and i:

→

Place actuator on the body.

→

Gently tighten the body screws in diagonal pairs without pres-

surization until the diaphragm is between the body and actuator.

do not fully tighten screws yet.

→

Pressurize the lower control air connection with compressed air

(value on type label) (see following „Fig. 7: Control air connection“).

→

Actuate the diaphragm valve twice.

→

Tighten the body screws to the permitted tightening torque

(see „Tab. 2: Tightening torques for diaphragms“).

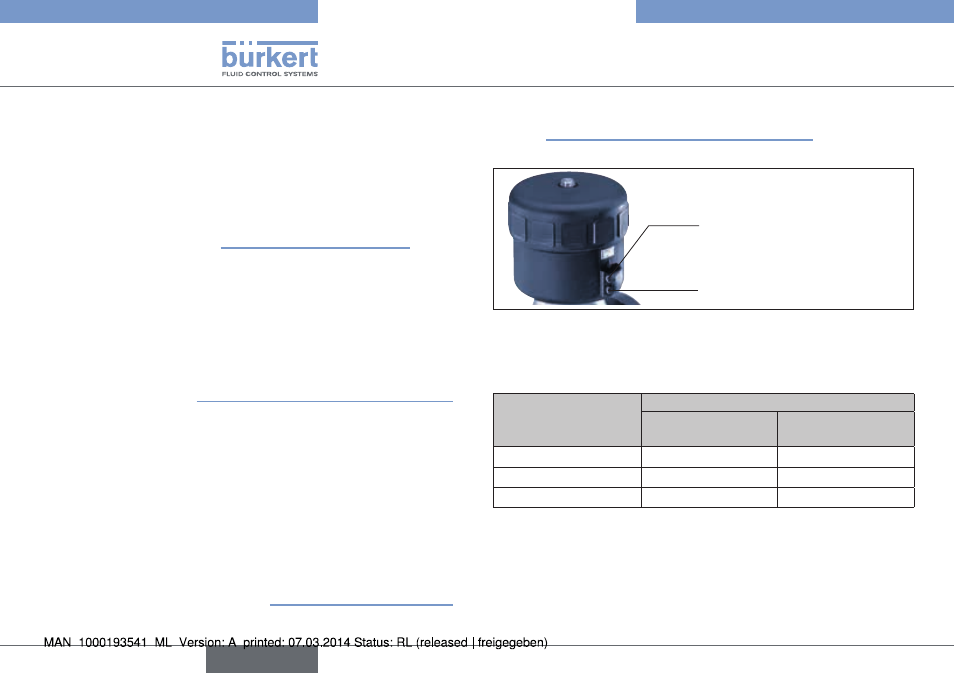

Upper control air connection

(for CFB and CFI)

Lower control air connection

(for CFA and CFI)

Fig. 7:

Control air connection

tightening torques for plastic body, Va tubular body (Va) and

forged body:

orifice

dn

[mm]

tightening torques for diaphragms [nm]

elastomer -

diaphragm

ptFe-diaphragm

65

20

30

80

30

40

100

40

50

Tab. 2: Tightening torques for diaphragms

english

Type 2030, 2031, 2031 K, 2032,

2033, 2037