Burkert Type 2037 User Manual

Page 10

10

Assembly

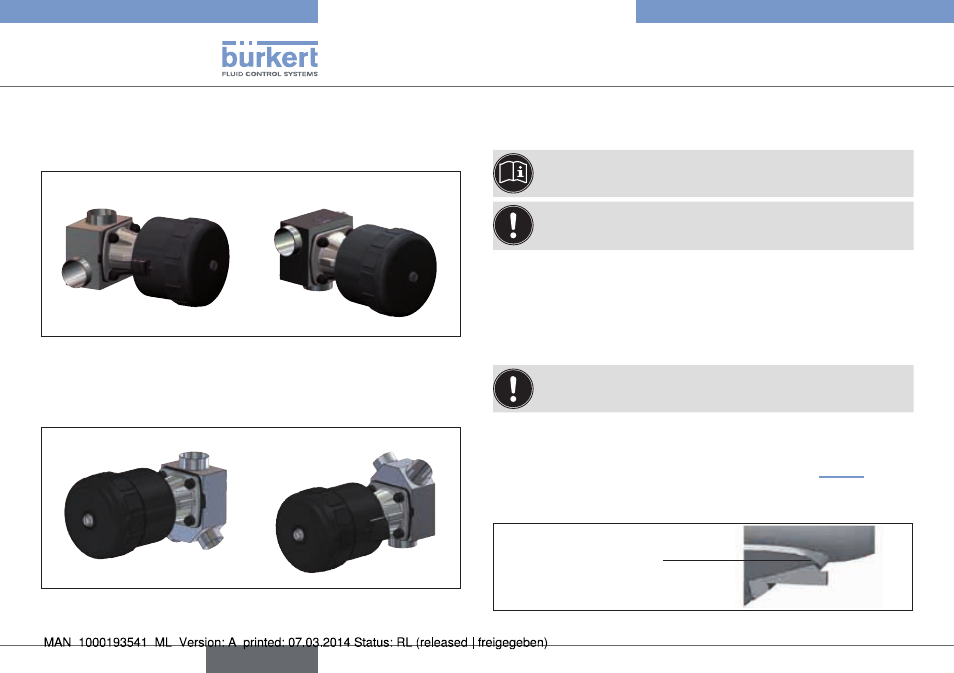

6.2.3 installation position T-valve type 2032

For the installation of the T-valves into circular pipelines, we recommend

the following installation positions:

For supply of a medium:

For removal of a medium:

Fig. 4:

Installation position of type 2032

6.2.4 installation position y-valve type 2037

For the installation of the Y-valves into systems, we recommend the

following installation positions:

For supply of a medium:

For removal of a medium:

Fig. 5:

Installation position of type 2037

6.2.5 installation of tank bottom valve

Type 2033

For information about tanks and welding instructions, refer to

the standard ASME VIII Division I.

We recommend that the valve is welded before the tank is

assembled. However, it is still possible to weld the valves to

completely installed tanks.

before welding, make sure that:

• the tank bottom valve does not impact any other device installation

component and that is always remains possible to assemble and

dismantle the actuator.

• a minimum distance between 2 welding points of 3x the thickness

of the tank wall is maintained.

To ensure that the tank drains optimally, the valve should be

welded in the middle of the drain

The diameter of the holes in the tank and in the flange must be equal.

The valve has two weld edges to simplify welding and positioning of

the valve. The weld edges are about 3 mm long. If the tank wall is more

than 3 mm thick, the valve must be positioned on the „Fig. 6“.

→

Grind the drain wall down,

→

Weld the valve in.

Position to be ground

on tank

Fig. 6:

Position to be ground on tank

english

Type 2030, 2031, 2031 K, 2032,

2033, 2037