10 malfunctions – Burkert Type 2012 User Manual

Page 21

21

Maintenance,Cleaning

Type 2012

→

Attach new valve seat to the installation tool.

→

Grease thread with a lubricant (e.g. Klüber paste UH1 96-402).

→

Place attached valve seat on the body thread and screw on by

hand.

→

Using a torque wrench, tighten to the specified tightening torque

(see “Tab. 5”).

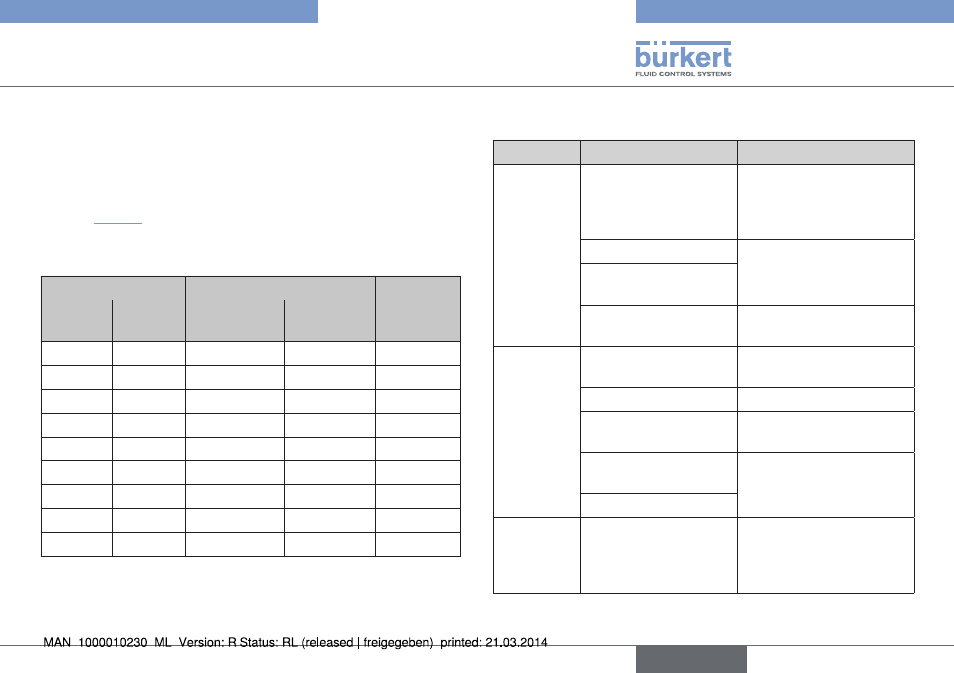

tightening torque for installation of seat

screw connection

tightening torques

tolerance

seat

Body

uncoated

seats

coated

seats

DN 4-15

DN 15

25

20

+3

DN 20

DN 20

35

28

+3

DN 25

DN 25

50

40

+5

DN 32

DN 32

80

65

+5

DN 40

DN 40

100

85

+8

DN 50

DN 50

120

120

+8

DN 65

DN 65

150

150

+10

DN 80

DN 80

180

180

+10

DN 100

DN 100

220

220

+10

Tab. 5: Tightening torque for installation of seat

10

malfuncTiOns

malfunction

reason

remedial action

Actuator

does not

switch

Pilot air port

interchanged

→

Connect lower (CFA,

CFI) or upper (CFB,

CFI) control air

connection

Pilot pressure too low

→

Observe pressure

specifications on the

type label

Medium pressure too

high

Flow direction reversed

→

Observe direction

arrow on the body

Valve is not

sealed

Dirt between seal and

valve seat

→

Installing dirt trap

Seat seal worn

→

Installing new seat seal

Flow direction reversed

→

Observe direction

arrow on the type label

Medium pressure too

high

→

Observe pressure

specifications on the

type label

Pilot pressure too low

Valve is

leaking on

the release

bore

Packing gland worn

→

Renew packing gland

or replace actuator

Tab. 6: Malfunctions

english