Burkert Type 2012 User Manual

Page 17

17

Replacingthesealset

Type 2000, 2002, 2012

→

Place a suitable open-end wrench on the wrench flat of the nipple

6

.

→

Unscrew actuator on the valve body

1

.

→

Remove compressed air from the control air connection.

→

Knock out pin

4

on swivel plate

3

with a suitable pin punch:

pin punch ø 3 mm for spindle diameter 10 mm and

pin punch ø 5 mm for spindle diameter 14 mm.

→

Remove swivel plate

3

.

→

Unscrew spindle guide

7

with the help of the installation tool and an open-end wrench.

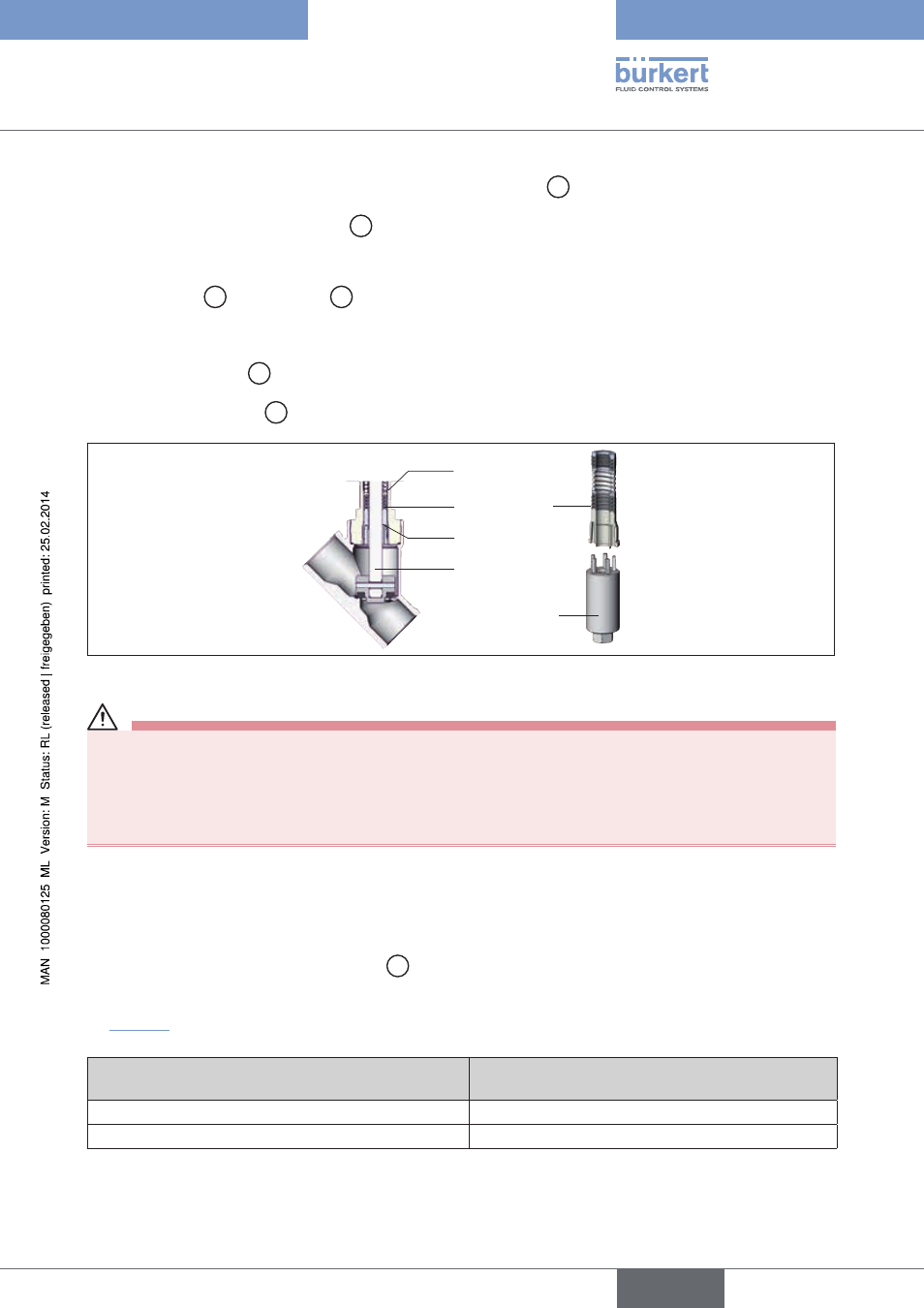

Installation wrench

Packing gland

Spindle guide

Spindle

Packing gland tube

Figure 4:

Change the packing gland

Warning!

Risk of injury from ejected parts!

When the spindle opening is exposed, the individual parts of the packing gland are pressed out at an undefined

speed when the control air connection is pressurized.

▶ Before pressurizing with control air, safeguard the ambient area of the discharge opening (e.g. place spindle

on a firm base).

→

Pressurize the lower control air connection with 6 bar – 8 bar.

→

Grease the individual parts of the new packing gland with the supplied lubricant.

→

Place the individual parts on the spindle in the prescribed direction and sequence.

→

Push packing gland packing into the tube

8

.

→

Screw in spindle guide again before using the installation wrench. Observe tightening torques according to

“Table 2”!

spindle diameter

(mm)

tightening torques

(nm)

10

6

14

15

Table 2:

Spindle guide tightening torques

english