Burkert Type 2012 User Manual

Page 2

Replacement InstRuctIons

The replacement instructions describe the procedure for converting

the control function of process valves of Type 2000 (angle seat valve)

and Types 2002 and 2012 (globe valves).

These instructions contain important safety information.

Failure to observe these instructions may result in hazardous

situations.

• The instructions must be read and understood before the

conversion.

symbols

→

designates a procedure which you must carry out.

Warning of serious or fatal injuries:

DAnGer!

In case of imminent danger.

WArnInG!

In case of potential danger.

Warning of minor or moderately severe injuries:

CAutIon!

DescRIptIon of the functIons

CFA

P

A

Closed in rest position by spring force

CFB

P

A

Opened in rest position by spring force

CFI

P

A

Actuating function via reciprocal

pressurization

Flow above the seat

The valve is closed by spring force (CFA) with the medium flow.

Medium pressure above the swivel plate supports the closing process

and contributes to sealing the valve seat. The valve is opened by the

control pressure.

Flow below the seat

Depending on the model, the valve is closed against the medium flow

by spring force (CFA) or by control pressure (CFB). Medium pressure

under the swivel plate contributes to opening the valve.

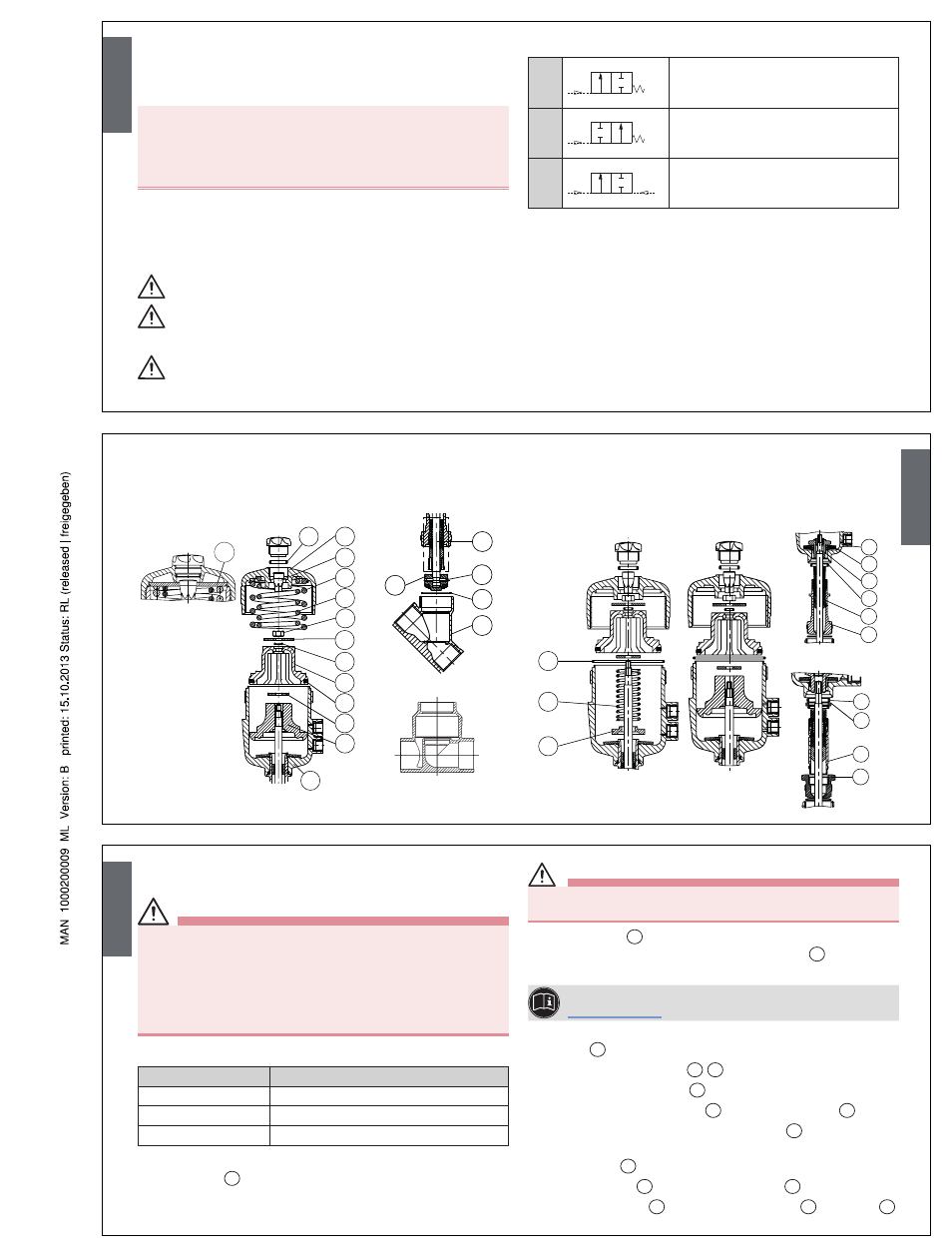

English

Actuators control function B (opened in rest position

by spring force) and I (dual acting)

30

35

19

CFB

CFI

only for version

ANTG E, F

only for version

ANTG D

11

6

10

8

12

17

18

11

7

6

eXploDeD-vIew DRawIng

Actuators control function A (closed in rest position by spring force)

12

19

20

23

22

21

24

25

28

29

26

31

32

CFA

2

4

5

1

3

Body Type

2000 and 2002

Body Type

2012

40

only for version

ANTG G, H

English

conveRsIon fRom contRol functIon

a (cfa) to contRol functIon b (cfb)

DAnGer!

Danger – high pressure!

• Turn off the pressure and vent the lines before loosening lines or

valves.

Risk of injury from improper maintenance!

• Maintenance may be performed by authorized technicians only!

• To screw on or unscrew valve body or actuator, use an open-end

wrench, never a pipe wrench, and observe tightening torques.

Required parts:

Item

Description

35

1 Pressure spring

30

1 O-ring

5

1 Graphite seal

Procedure:

→

Mount valve

1

on the body.

CAutIon!

Danger through taut springs!

• Carefully open piston actuator!

→

Release cover

31

with special wrench until the springs are

completely relaxed, holding up the actuator body

12

against the

hexagon.

For information about the special wrench, see Chapter

“Installation tools”.

→

For actuator size G (100 mm) and H (125 mm): Remove

washer

40

.

→

Remove pressure springs

28

29

.

→

Remove position indicator

26

with Allen key.

→

Screw actuator on the nipple

6

out of the valve body

1

.

→

Carefully screw in actuator on the swivel plate

3

(only put pressure

on the upper section of the swivel plate).

→

Release nuts

25

.

→

Remove pistons

22

with supporting washer

24

.

→

Remove filler piece

19

with intermediate washer

20

and O-ring

21

.

English