Brooks – Brooks Instrument 5851EM User Manual

Page 42

4-4

Brooks

®

Models 5965, 5851EM

Section 4 Maintenance

& Troubleshooting

Installation and Operation Manual

X-TMF-5965-5851EM-MFC-eng

Part Number: 541B122AAG

September, 2009

2. Connect the controller to a source of the gas on which it was originally

calibrated. Command 100% flow and adjust the inlet and outlet

pressures to the calibration conditions. Verify that the output signal

reaches and stabilizes at 5.000 Volts. Vary the command voltage over

the 2-to-100% range and verify that the output signal follows the

setpoint.

Apply +15 Volts to the valve override input (refer to Figs. 2-2, 2-3

and 2-4 for terminal assignments) and verify that the output exceeds

5.000Volts.

Apply -15 Volts to the valve override terminal (connect valve override

pin +0 ground for current l/O versions) and verify that the output signal

falls below 0.100 Volts. lf possible, connect a flow measurement device

in series with the mass flow controller to observe the actual flow

behavior and verify the accuracy of the mass flow controller. lf the mass

flow controller functions as described above, it is functioning properly

and the problem is most likely elsewhere. Table 4-1 lists possible

malfunctions which may be encountered during bench troubleshooting.

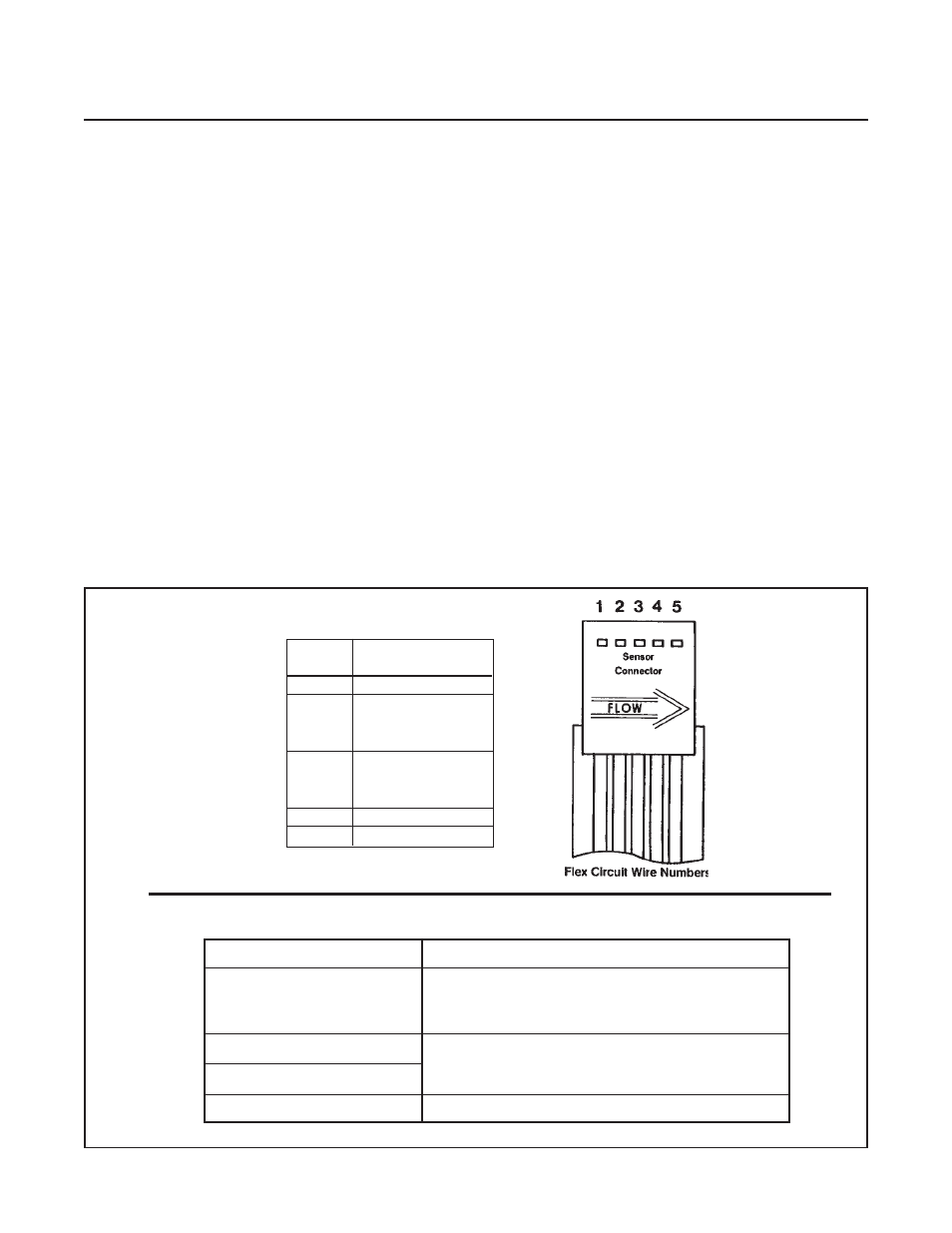

Table 4-2 Sensor Troubleshooting

Remove the sensor connector from the PC Board for this procedure.

OHMMETER CONNECTION

RESULT IF ELECTRICALLY FUNCTIONAL

Open circuit on ohmmeter. If either heater (1) or

Pin 1 or 4 to meter body

sensor common (4) are shorted, an ohmmeter

reading will be obtained.

Pin 4 to Pin 2

Nominal 1100 ohms reading, depending on

Pin 4 to Pin 3

Pin 5 to Pin 1

Nominal 1200 ohm reading.

temperature and ohmmeter current.

SENSOR

SCHEMATIC

PIN

NO.

FUNCTION

1

Heater

Upstream

2

Temperature

Sensor (Su)

Downstream

3

Temperature

Sensor (Sd)

4

Sensor Common

5

Heater Common