Brooks – Brooks Instrument 5851EM User Manual

Page 28

3-2

Brooks

®

Models 5965, 5851EM

Section 3 Operation

Installation and Operation Manual

X-TMF-5965-5851EM-MFC-eng

Part Number: 541B122AAG

September, 2009

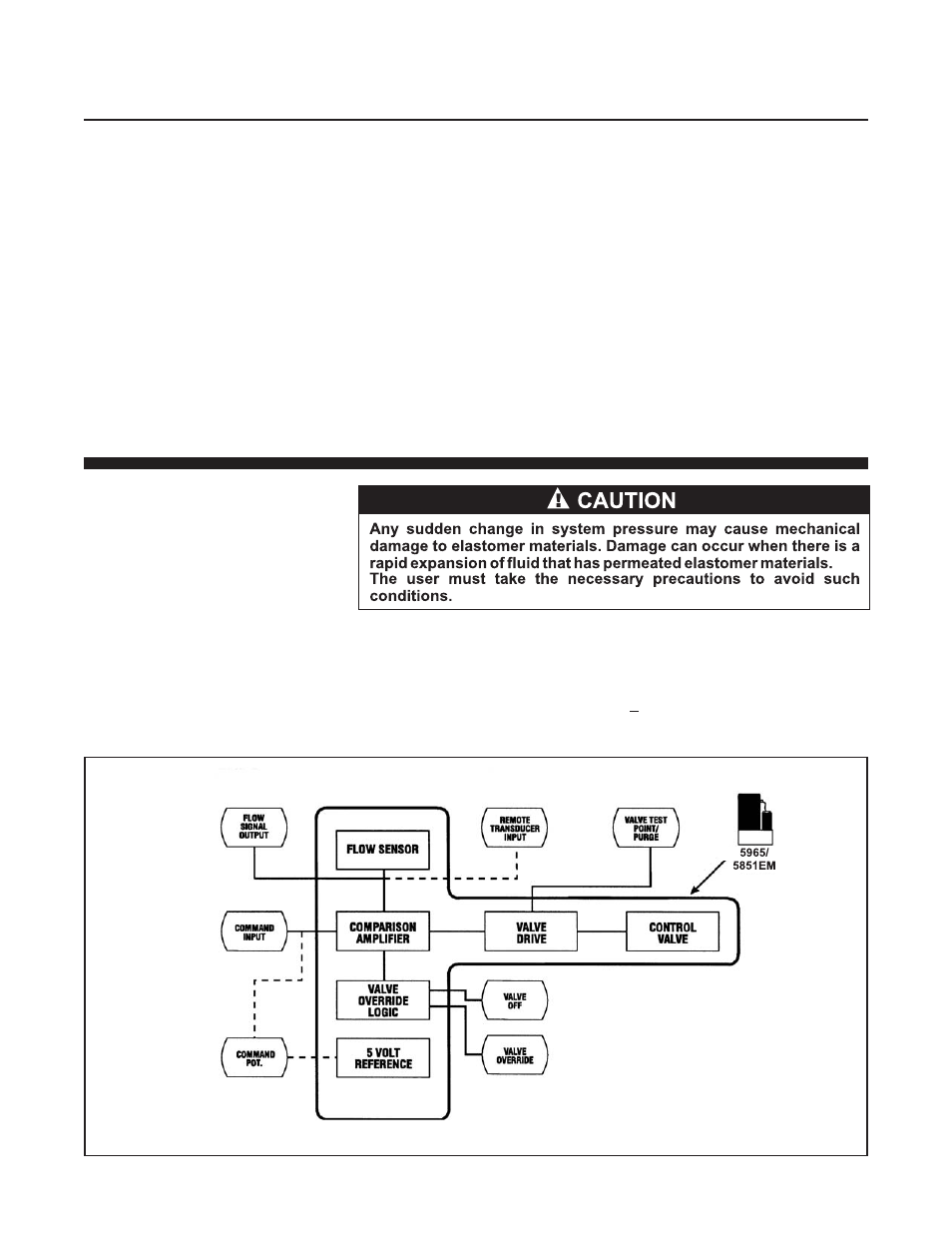

Figure 3-2 Flow Control System Block Diagram

The flow restrictor shown in Figure 3-1 peforms a ranging function similar

to a shunt resistor in an electrical ammeter. The restrictor provides a

pressure drop that is linear with flow rate. The sensor tube has the same

linear pressure drop/flow relationship. The ratio of the restrictor flow to the

sensor tube flow remains constant over the range of the meter. Different

restrictors have different pressure drops and produce controllers with

different full scale flow rates. The span adjustment, in the electronics,

affects the fine adjustment of the controller’s full scale flow

ln addition to the mass flow sensor, the Model 5965/5851EMEM mass flow

controller has an integral control valve and control circuit as shown in

Figure 3-2.The control circuit senses any difference between the flow

sensor signal and adjusts the current in the modulating solenoid valve to

increase or decrease the flow.

3-2 Operating Procedure

a. Apply power to the controller and allow approximately 45 minutes for

the instrument to warm up and stabilize its temperature.

b. Turn on the gas supply.

c. Command zero percent (0%) flow and observe the controller’s output

signal. lf the output is not zero mVdc (+10 mVdc), check for leaks and,

if none are found, refer to the re-zeroing procedure in Section 3-3.