FlexLink Направляющие и опорные салазки (пластик) Монтаж User Manual

Page 5

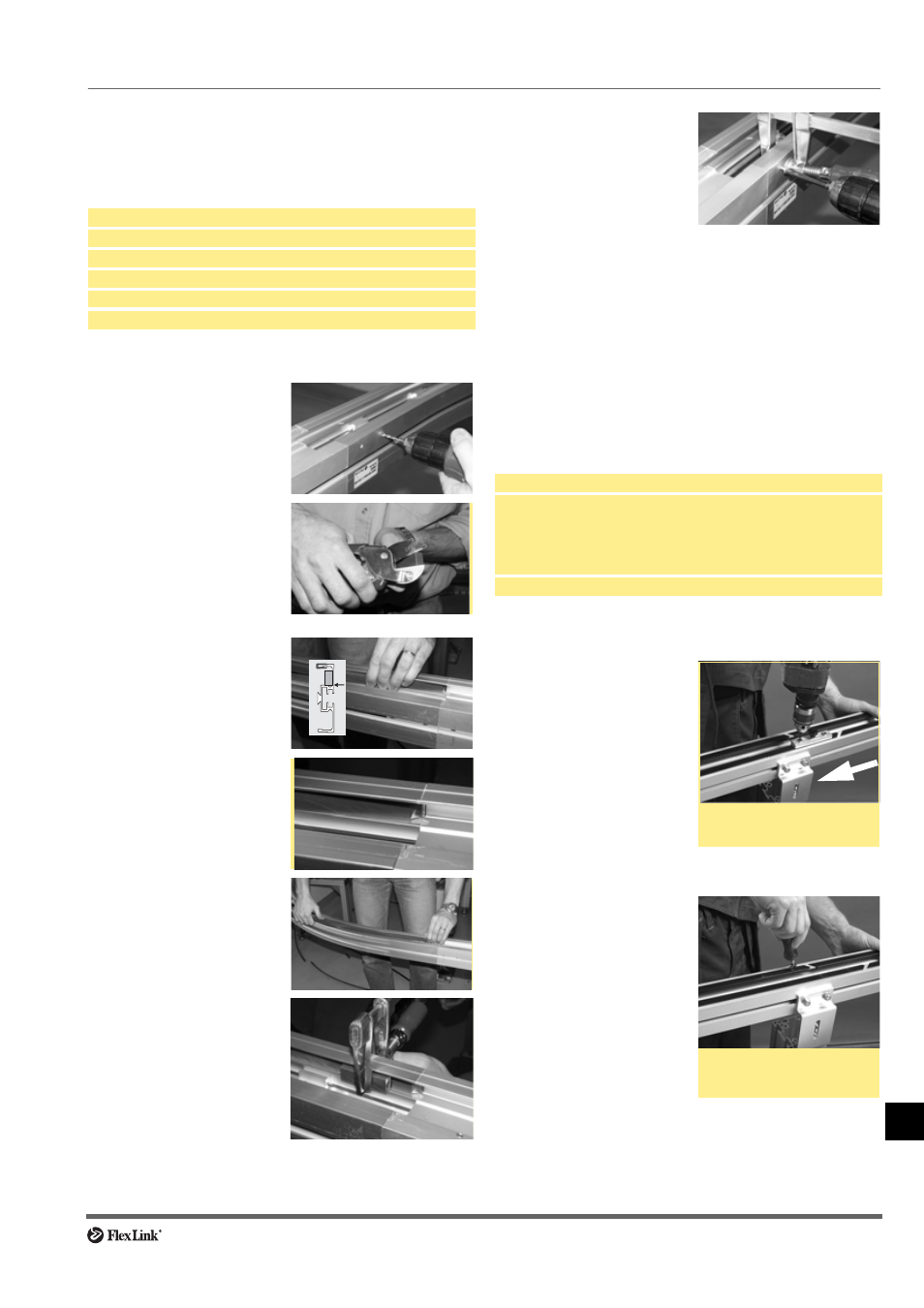

A. Installation of plastic slide rail and support rail

463

PO

X45

XS

XL

XLP

X85

X85P

XH

XK

XKP

X180

X300

GR

CS

XT

XC

XF

XD

FST

XLX

X85X

X180X

X300X

GRX

CSX

ELV

CTL

TR

APX

IDX

A. Installation of plastic slide rail and support rail (continued)

Mounting support rail in plain bends

The friction in plain bends can be significantly reduced by

using support rails in the inner beam profile.

Tools required

Procedure

Anchoring the slide rail

The beginning of each slide rail section must be fixed to

the beam, since the chain will cause the slide rail to be

pushed forward. Slide rail which moves into a wheel bend

or a drive unit can block the chain completely.

There are two different methods for fixing slide rail to

the conveyor beam, using aluminium rivets or plastic

screws. Either method can be used, but the riveting

method is more secure if the conveyor will run with high

operational speed or be heavily loaded.

Tools required

Procedure – drilling

Soft hammer

Knife

Drill 4,2 mm

Clamp

Screwdriver

Sheet metal screws ISO 7049 4,2×9,5

1 Drill two holes (4,2 mm) in

the beam at the entry and

exit of the bend. Drill

additional holes every

200–300 mm.

2 Cut both ends of the rail

at a 45° angle.

3 Press the support rail into

place at one end of the

bend. It is important that it

is mounted against the

bottom flange of the

beam.

4 Make sure that the rail

starts exactly at the joint

between the bend and

the straight conveyor

beam.

5 Press the rest of the sup-

port rail in place.

6 Clamp the rail.

7 Fix with BSS ST 4,2×9,5

sheet metal screws

(never use screws longer

than 9,5 mm).

Hand drill

Drill fixture for slide rail:

Part #3924774 (drill diameter 3,2 mm): XS*

Part #3920500 (drill diameter 4,2 mm): XS**-XL-X85/XM-XH-XK-

X180/X300

* Rivet method only

**Plastic screw method only

Countersink

1 Drill two holes near the

beginning of each slide

rail section. Use the drill

fixture to ensure clean-

cut holes and the correct

location of the holes.

The holes must be at the

leading edge of the joint

piece, in the direction of

travel, to hold the slide rail

in place when the con-

veyor is in use. Use a well

sharpened drill bit.

2 Use a countersink to

deburr and countersink

the holes. Also make sure

that there are no metal fil-

ings left underneath the

slide rail.

Arrow indicates direction

of travel