Example of available slide rail types – FlexLink Направляющие и опорные салазки (пластик) Монтаж User Manual

Page 2

460

A. Installation of plastic slide rail and support rail

A. Installation of plastic slide rail and support rail (continued)

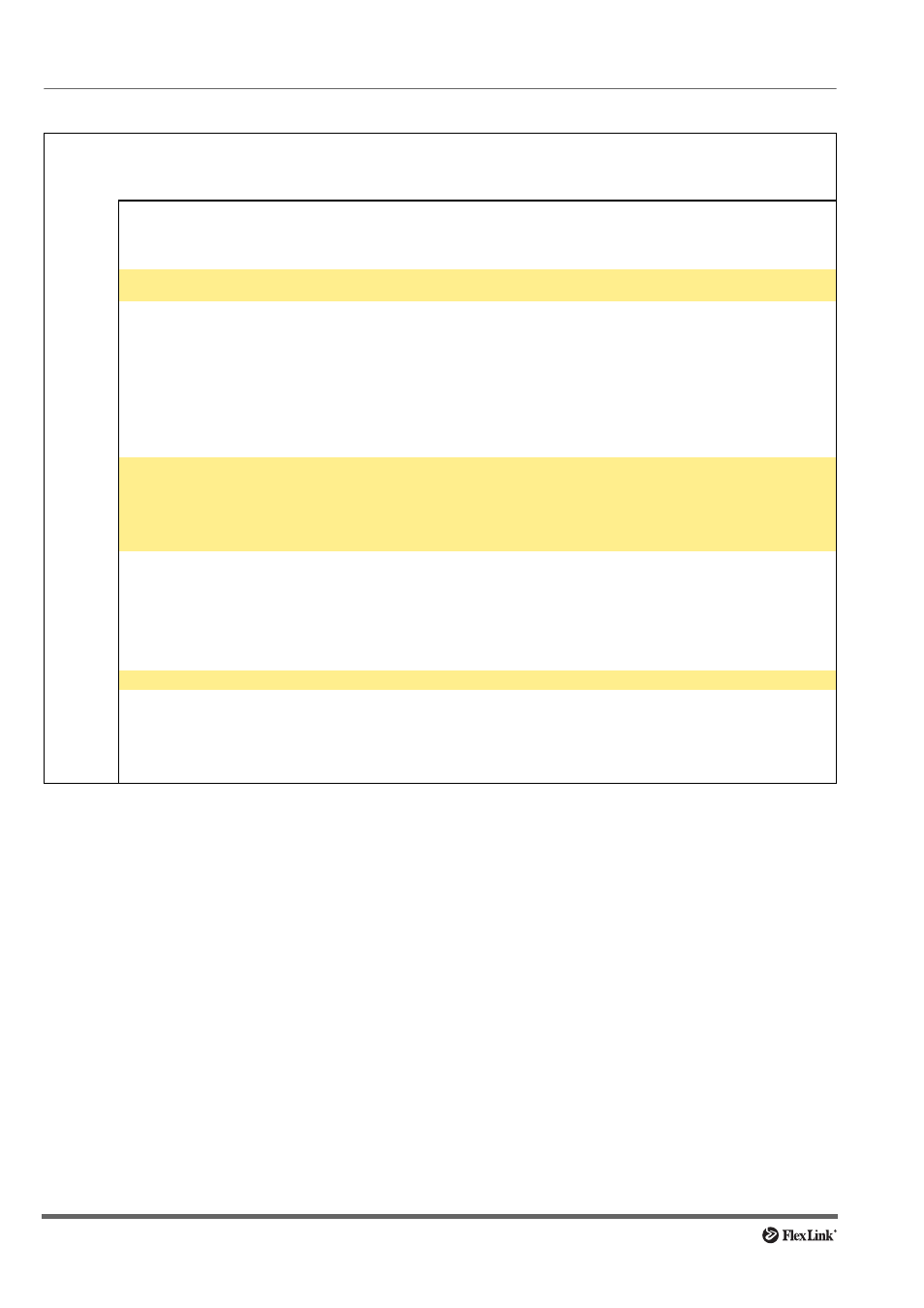

Example of available slide rail types

Slide rail

type

XSCR 25

XLCR 25

XBCR 25

XSCR 25 P

XLCR 25 P

XWCR 25 P

XLCR 25 H

XSCR 25 U

XLCR 25 U

XKCR 25 U

XWCR 25 U

XBCR 3/6 UA

XLCR 25 E

XBCR 25 E

XBCR 25 EB

XBCR 3 EA

XLCR 3 TA

XKCR 3 TH

XKCR W.. TH

Material

HDPE

High density pol-

yethylene

PVDF

Polyvinylidene

fluoride

PA-PE

Polyamide-poly-

ethylene

UHMW-PE

Ultra-high

molecular weight

polyethylene

UHMW-PE

Carbon filled

ultra-high molec-

ular weight poly-

ethylene

SS

Stainless steel

--

Hardened steel

Friction

coefficient

0,1–0,25

0,15–0,35

0,1–0,30

0,1–0,25

0,15–0,30

0,15–0,35

0,15–0,35

Application

information

–40 to +60 °C

Standard appli-

cations

–40 to +100 °C

High resistance

to chemicals

(see table in the

Product cata-

logue)

Accumulation

Transport of

heavy parts

High speed

Abrasive parti-

cles

–40 to +80 °C

Accumulation

Transport of

heavy parts

High speed

Abrasive non-

metal particles

–40 to +60 °C

High wear resist-

ance

Clean environ-

ment

Low dust and

particle genera-

tion

–40 to +60 °C

Reduces static

electricity

Relatively low

dust and particle

generation

Abrasive parti-

cles

High resistance

to chemicals

Abrasive parti-

cles such as

metal chips from

milling and grind-

ing processes

Advantages Good standard

Easy to mount

Chemical and

heat resistant

Low elongation

More resistant to

chemicals

Good wear and

heat resistance

Easy to mount

Low wear out

Minimum of par-

ticles

High conductivity

Fast discharge

Easy to mount

No elongation

High resistance

to chemicals and

abrasive parti-

cles.

Heat resistant

Low wear out

No elongation

Very high resist-

ance to abrasive

particles

Heat resistant

Low wear out

Disadvan-

tages

Poor resistance

to solvents

(petroleum,

white spirit)

Limited tempera-

ture range

Wear out at

heavy accumula-

tion

Higher friction

More difficult to

mount

Should not be

used in wet

applications

Limited tempera-

ture range

Higher elonga-

tion

Some particle

generation may

occur

Difficult to

mount, with only

straight lengths

High friction

Generates parti-

cles in dry envi-

ronments

Special mount-

ing procedure

High friction

Generates parti-

cles in dry envi-

ronments

Colour

Black

Natural white

Grey

White

Black

Natural

Natural

Suitable

application

areas

All industries

Medium speed

Medium load

Greasy environ-

ments

Water (washing

machines)

Chemicals

High load

Heat resistant

High speed

High load

All types of clean

production

Environments

sensitive to static

electricity

High load

Heat/cold

Aggressive parti-

cles

High load

Heat/cold