Part 2 - electrical installation – Dynasonics 901 Series Enhanced Ultrasonic Flow Meter User Manual

Page 19

Rev.

04/02

-18-

D901/M

enclosure. Secure the transducer cable with the

supplied conduit nut.

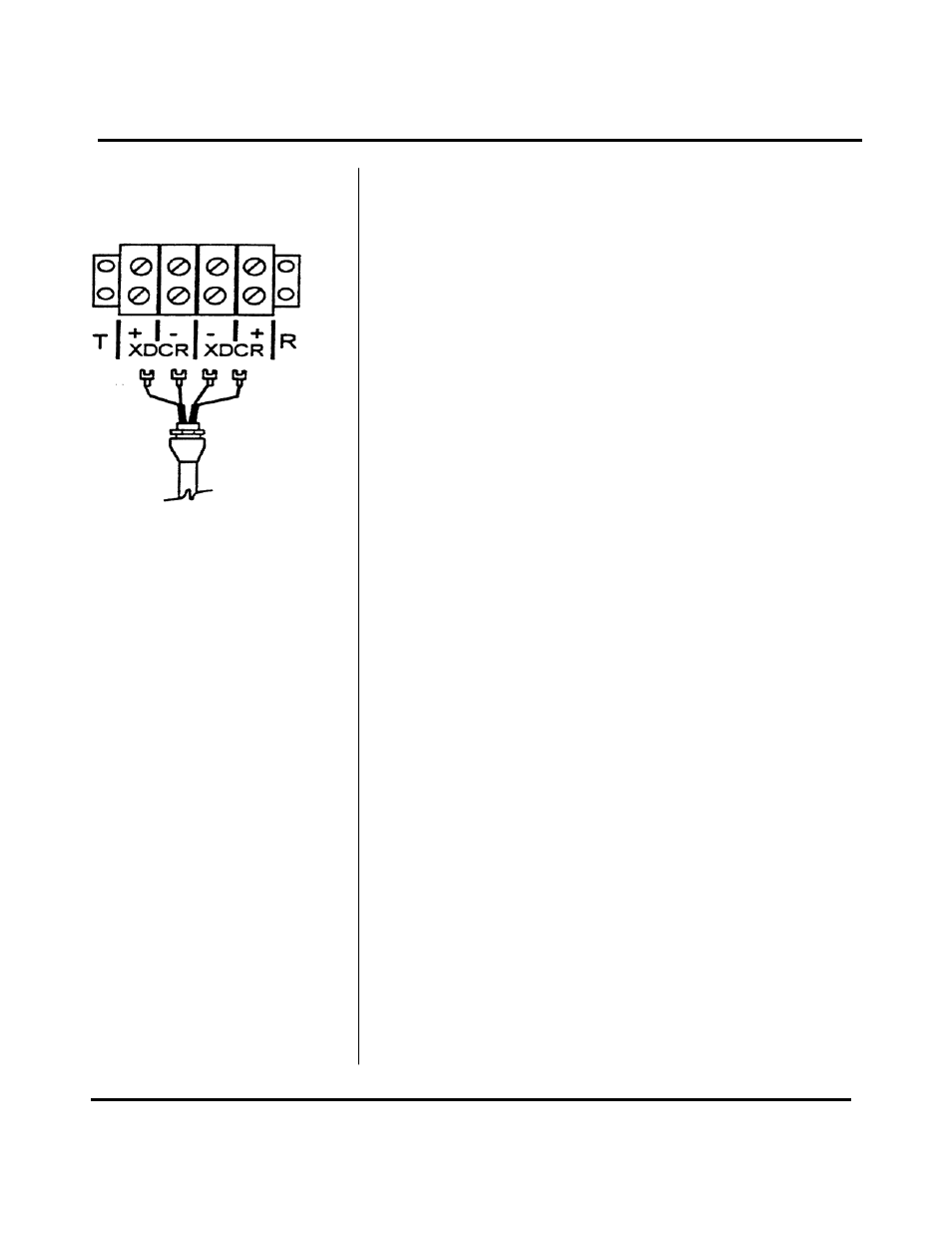

2. The terminals on the transducer cable are coded with

wire markings. Connect the appropriate wires to the

corresponding screw terminals in the transmitter. See

Figure 9.

NOTE: The transducer cable carries low level signals.

Do not attempt to add additional cable to the factory

supplied transducer cable. If additional cable is required,

contact the Dynasonics factory to arrange for an exchange

transducer with the appropriate length of cable. Cables to

300 feet [ 90 meters ] are available.

The 4-20mA output is proportional to the flow rate

measuring scale and can drive a load of up to 600 ohms.

The output is isolated from earth ground and circuit low.

Connect the load to the 4-20 mA screw terminals on the

transmitter terminal block, matching polarity as indicated.

NOTE: An additional hole in the transmitter enclosure is

required for outputs. Drill the hole in the the enclosure

bottom taking care not to drive the drill bit into wiring or the

circuit boards with the transmitter.

The pulse output is proportional to the flow rate measuring

scale. This output may be used one of two ways:

♦ To drive a 12V logic device.

♦ To drive a low impedance, 12V device. Minimum

resistance 50 ohms.

The pulse output is adjustable from a range of 0 - 600 Hz

to 0 - 10kHz via control R29 [CTR] located on the left side

of the signal processing PCB in the back of the enclosure.

The pulse width is fixed at 50 µ seconds. CTR “ - ”

represents circuit low. CTR “ + “ represents 12 Vdc pulse

output.

PART 2 - ELECTRICAL INSTALLATION

Figure 9

Pulse Output

4-20 mA Output

Transducer Connections