Part 2 - transducer installation – Dynasonics 901 Series Enhanced Ultrasonic Flow Meter User Manual

Page 14

Rev.

04/02

-13-

D901/M

PART 2 - TRANSDUCER INSTALLATION

Before the transducer heads are bonded to the pipe

surface, an area slightly larger than the flat surface of the

transducer must be cleaned to bare metal on the pipe.

(Plastic pipes do not require preparation beyond removal

of paint.) Remove all scale, rust and paint. Thoroughly

dry and degrease the mounting surfaces.

NOTE: Small pits in the piping surface typically do not

significantly impact ultrasonic transmission or signal

reception.

After selecting the applicable mounting location and

preparing the piping surface as detailed in A and B, the

transducer can be mounted to the pipe.

To assure an acoustically conductive path between the

transducer face and the prepared piping surface, a

coupling compound is employed. Enclosed with the D901/

M system is tube of Dow Corning RTV-732. This couplant

is satisfactory for permanently mounting the transducers

to the pipe. If the installation is temporary (less than a few

days), Dynasonics recommends utilizing a silicone-based

grease such as Dow Corning 111. The grease chosen

must be rated to not flow at the temperature of the pipe.

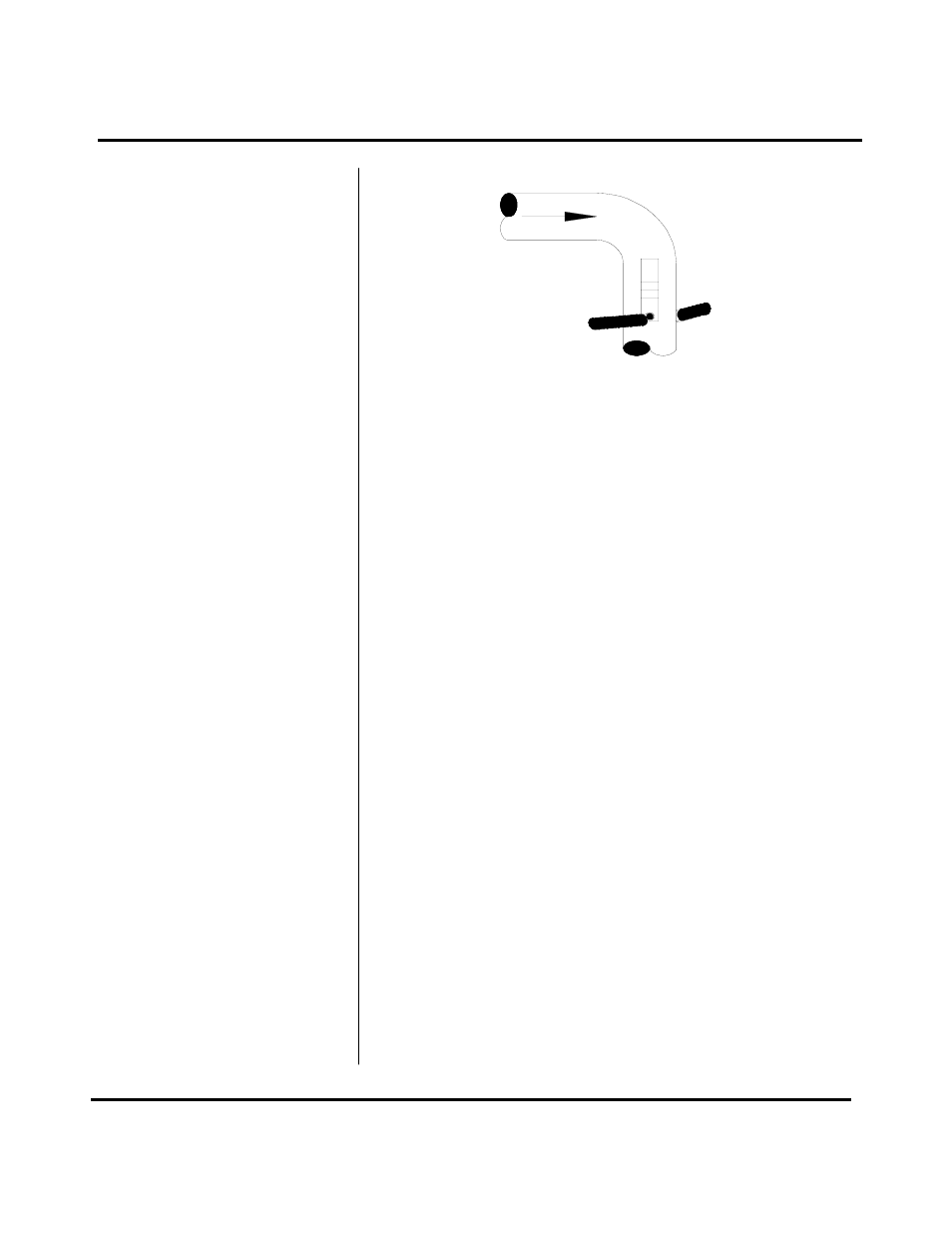

Figure 6

STEP B -

PIPE SURFACE

PREPARATION

STEP C -

TRANSDUCER

MOUNTING