Part 2 - transducer installation – Dynasonics 901 Series Enhanced Ultrasonic Flow Meter User Manual

Page 13

Rev.

04/02

-12-

D901/M

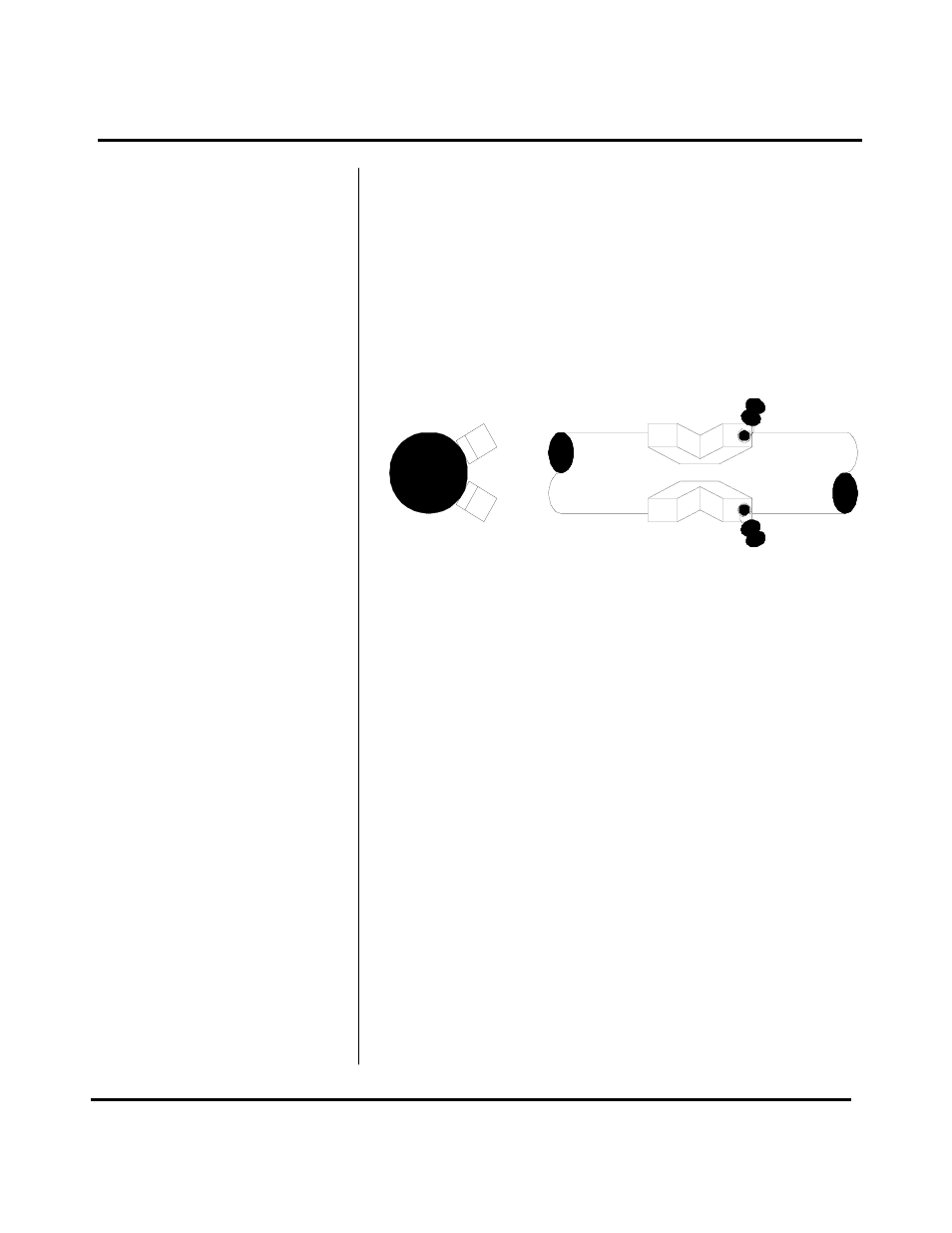

The mounting location and straight pipe requirements for

CASE 2 liquid characteristics are the same as those

describe in CASE 1. The difference will be in the location

of the transducers on the pipe. As the discontinuities

(suspended solids or aeration) reach a level of

approximately 1% or 10,000 PPM, sound can no longer be

reliably transmitted through the liquid as it has a tendency

to scatter and absorb into the high concentration of

discontinuity. To compensate for this, the D901/M

transducers can be located on the same region of the

pipe. In a horizontal pipe, mount the transducers at 2

o’clock and 4 o’clock positions. (Assuming 12 o’clock as

the top of the pipe.) See Figure 5.

Liquid that contains fewer than 25 PPM of 30 micron

or larger suspended solids or aeration. Or, liquid that

contains solids or aeration which is smaller than 30

microns.

The transducers will be mounted 1 to 3 pipe diameters

downstream from a 90° elbow. The orientation of the

transducers on the pipe will be 180° apart and facing each

other and 90° out of the plane of the elbow. See Figure 6.

PART 2 - TRANSDUCER INSTALLATION

CASE 3:

Figure 5