Communication Concepts AN779 Application Note User Manual

Page 3

AR

C

HIVE INF

O

RMA

TI

O

N

PRODUCT TRANSFERRED T

O

M/A

–

COM

AN779

3

RF Application Reports

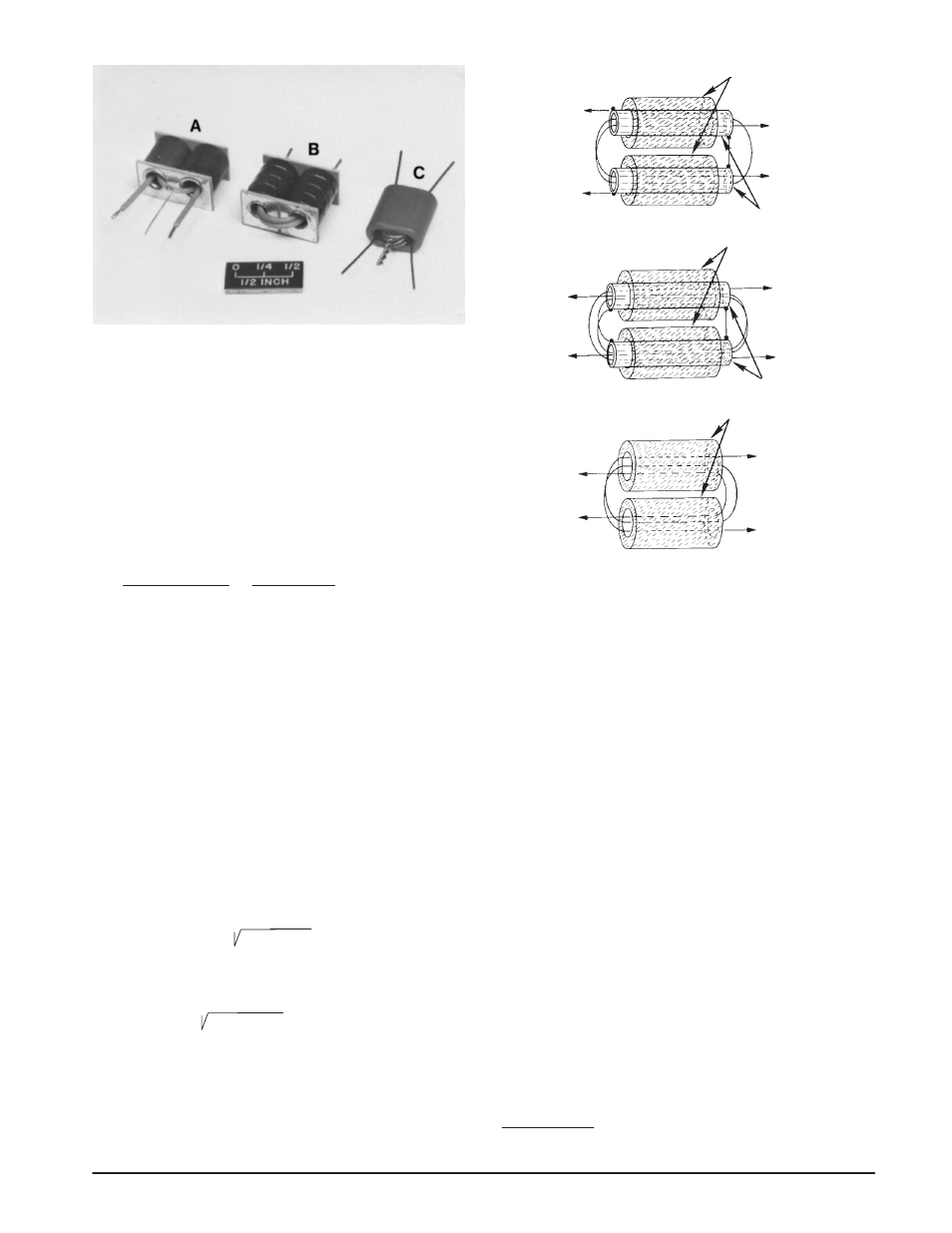

Figure 3. Examples of broadband transformers.

Variations of these are used in all designs of this article

(see text). All ferrites in transformers are Fair-Rite

Products Corp. #2643006301 ferrite beads.*

and impedance levels are relatively high. Problems were en-

countered especially with the output transformer design,

where an inductance of 4

µH minimum is required in the one-

turn winding across the collectors, when the load impedance

is

20

2 (13.6 – 2.5)

2

= 12.3 ohms.

4,8

=

P

out

2 (V

CE

– V

CEsat

)

2

Ferrites having sufficiently low-loss factors at 30 MHz

range only up to 800 – 1000 in permeability and the

inductance is limited to 2.5 – 3.0

µH in the physical size

required. This would also limit the operation to approximately

4 MHz, below which excessive harmonics are generated and

the efficiency will degrade. One possible solution is to

increase the number of turns, either by using the metal tubes

for only part of the windings as in Figure 4B, or simply by

winding the two sets of windings randomly through ferrite

sleeves or a series of beads (Figures 3C and 4C). In the

latter, the metal tubes can be disregarded or can be used

only for mounting purposes. T3 was eventually replaced with

a transformer of this type, although not shown in Figure 1.

Below approximately 100 MHz, the input impedances of

devices of the size of MRF475 and smaller are usually

capacitive in reactance, and the X

s

is much smaller than the

R

s

, (Low Q) For practical purposes, we can then use the

formula

(Rs

2

+ X

s

2

)

to find the actual input impedance of the device. The data-

sheet numbers for 30 MHz are 4.5, –j2.4 ohms, and we get

(4.5

2

+ 2.4

2

) = 5.1 ohms.

The base-to-base impedance in a push-pull circuit would be

four times the base-to-emitter impedance of one transistor.

However, in Class AB, where the base emitter junction is for-

ward biased and the conduction angle is increased, the im-

pedance becomes closer to twice that of one device. The

rounded number of 11 ohms must then be matched to the

Metal Tubings

Metal Tubings

Ferrite Sleeves

Ferrite Sleeves

Ferrite Sleeves

Lo Z

Hi Z

Hi Z

Hi Z

Lo Z

Lo Z

A

B

C

Figure 4. The turns ratios shown above are imaginary

and do not necessarily lead to correct design practices

driver output. The drive power required with the 10 dB speci-

fied minimum gain is

P

out

/Log

–1

(G

PE

/10) = 2.0 W

and the driver output impedance using the previous formula

is 2(11.1

2

)/2 = 123 ohms. The 11 ohms in series with the

gain-leveling networks (C8, R8 and C9, R11) is 17 ohms.

The closest practical transformer for this interface would be

one with 9:1 impedance ratio. This would present a higher-

than-calculated load impedance to the driver collectors, and

for the best linearity the output load should be lower than re-

quired for the optimum gain and efficiency. Considering that

the device input impedance increases at lower frequencies,

a better overall match is possible with a 4:1, especially since

the negative feedback is limited to only 4 dB at 2 MHz due to

its effect on the efficiency and linearity.

The maximum amount of feedback a circuit can tolerate

depends much on the physical layout, the parasitic

inductances, and impedance levels, since they determine the

phase errors in the loop. Thus, in general, the high-level

stages should operate with lower feedback than the low-level

stages.

The maximum amount of feedback the low-level driver

can tolerate without noticeable deterioration in IMD is about

12 dB. This makes the total 16 dB, but from the data sheets

we find that the combined gain variation for both devices

from 2 to 30 MHz is around 29 dB. The difference, or 13 dB,

should be handled by the gain–leveling networks.

*Wallkill, N.Y. 12589