CEMB USA C88 EVO (C) User Manual

Page 17

17

Use and maintenance manual Rev. 02-2010

ENGLISH

5.10 ECCENTRICITY MEASUREMENT

5.10.1 When and why matching

The software associated with eccentricity measurement is

a powerful tool for determining the need to perform relative

rotation between the rim and tyre in order to reduce the eccen-

tricity of the wheel down to acceptable limits. The principle

adopted is based on the consideration that a rim with acceptable

tolerance, mounted with an acceptable tyre, can statistically

generate a total eccentricity which is not acceptable but can

be improved by matching.

Generally speaking, rim measurement is not necessary,

accurate or useful because:

To measure the rim it is necessary to remove the tyre.

▪

There can by coarse errors on the outside (e.g. alumi-

nium wheels!)

The two rim sides can be eccentric in a very different

▪

way. Therefore to which one to make reference? What

is the effect on the tyre mounted?

To improve the eccentricity of a wheel,

▪

the rim should be

eccentric

, to compensate the tyre. And viceversa.

If after a rotation by 180° of a wheel, the value is still

▪

out-of-tolerance, either the tyre or rim are too eccentric:

One of the two must be replaced!

Use of the wheel balancer

wheel

rim

tyre

rotation axle

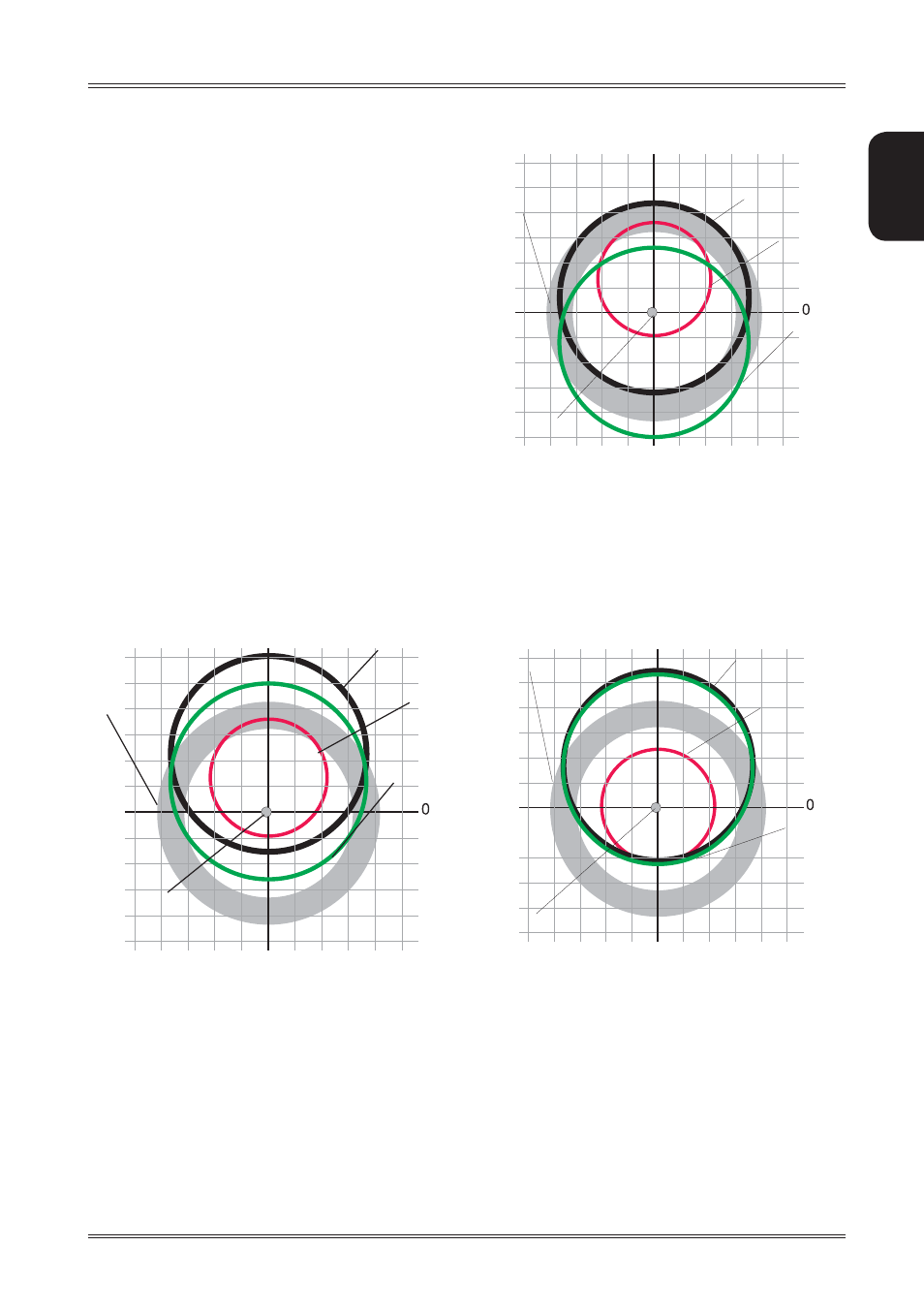

Ideal wheel

Example 1

Rim + 0.8 mm

Tyre + 0.6 mm

Wheel + 1.3 mm

Eccentricity of the wheel is excessive, due to an acceptable

rim or tyre but randomly placed in an “unfortunate” relative

position.

Example 2

Rim + 0.8 mm

Tyre - 0.6 mm

Wheel + 0.3 mm

Eccentricity of the single items has been compensated.

The wheel is acceptable.

SOLUTION:

Rotate the tyre on the rim by 180°

RESULT:

wheel eccentricity 0.3 - 0.4 mm (in tolerance)

SOLUTION:

Rotate the tyre on the rim by 180°

RESULT:

no improvement is obtained.

Example 3

Rim 0 mm

Tyre + 1.2 mm / 0,045”

Wheel + 1,2 mm / 0,045”

Eccentricity of the wheel cannot be

compensated by the rotation because

the rim is perfect!

wheel

rim

tyre

rotation axle

Ideal wheel

wheel

rim

tyre

rotation axle

Ideal wheel