6 wheel locking – CEMB USA C88 EVO (C) User Manual

Page 15

15

FI

FE

Use and maintenance manual Rev. 02-2010

ENGLISH

unbalance split function enable

acquisition of new dimensions (

AUTOMA

TIC POSITION REPEATER

) enable indication of

the longitudinal position of the out-of-balance

(

INDICATION OF EXACT CORRECTION

WEIGHT POSITION

)

selection of special functions

balancing

run.

INDICATION

If the machine remains on this screen without being

used for more than the time preset in the Setup

parameters, the screen automatically returns to the

screen-save.

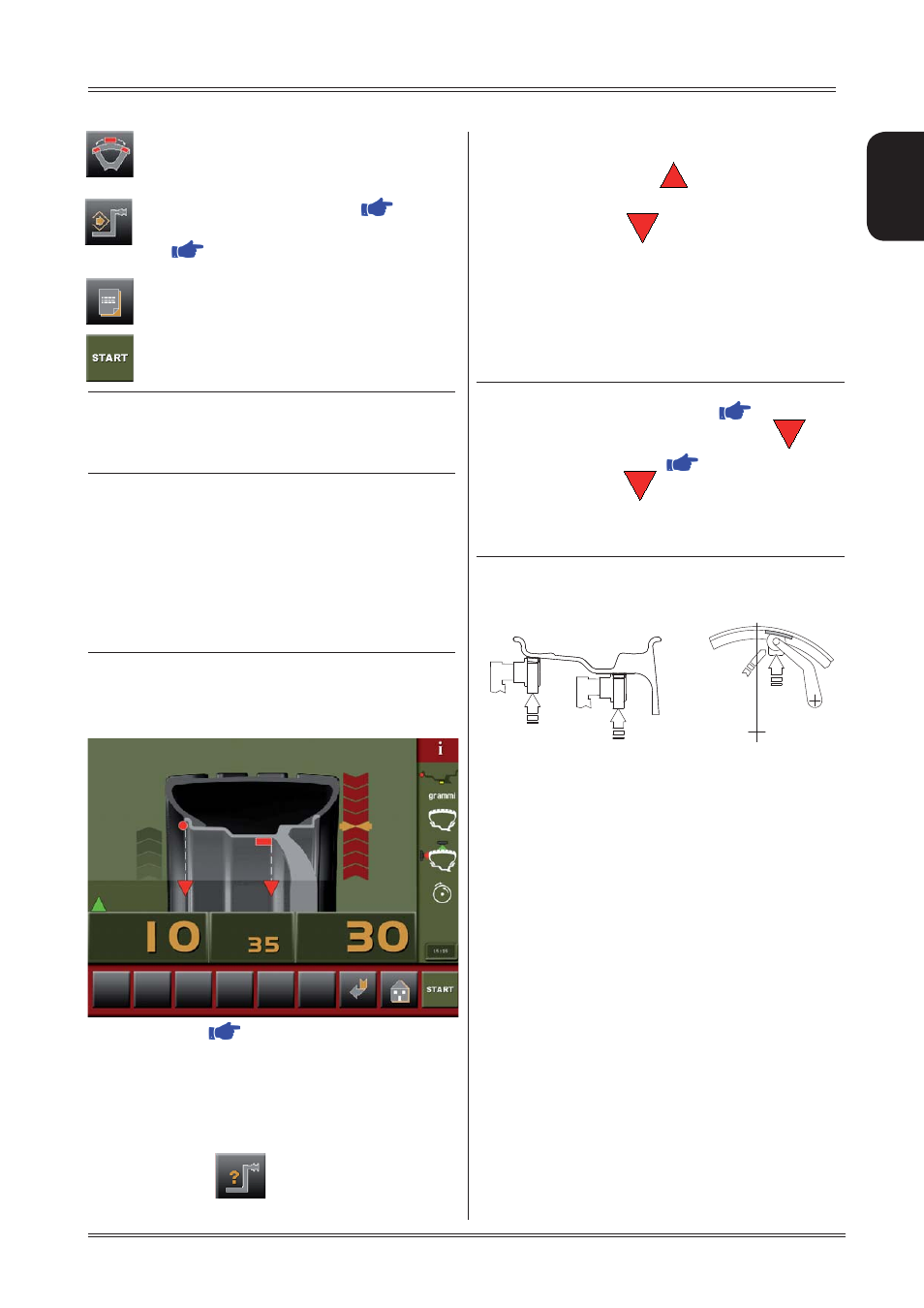

5.6 WHEEL LOCKING

The wheel is automatically locked when reaching the correct

angular position for weight application on the inside and

outside, turning it slowly by hand. To unlock the wheel, turn

it hard to move it from the correct correction position.

If the unbalance is within tolerance, the wheel is not

automatically locked.

5.7 EXACT POSITIONING OF THE ADHESIVE

WEIGHT BY MEANS OF THE GAUGE

WITH CLIPS

Option enabled (

AUTOMATIC POSITION REPEA-

TER

)

:

pull out the gauge to automatically access the function

▪

If the option is disabled, the position repeater screen can

be accessed in 2 different ways:

Pull out the gauge after placing the wheel in the correc

▪

tion position on one of the two sides

Press the button

▪

at any time

Always pull out the gauge to position A as shown in fi gure

page 13

A mobile coloured arrow [

▪

] indicates the approach

of the weight towards the correction position.

W

▪

hen a fi xed arrow [

] is reached, rotate the wheel

to correction position (FI or FE) and apply the

counterweight by rotating the gauge tip towards the

outside, into the position where the pincer touches the

wheel

(

where appropriate use the weight pusher

).

The correction weight application position is automati

▪

cally reset in relation to the position of the distance +

diameter gauge (pos. A).

INDICATION

When the acoustic signal is enabled (

ACOUSTIC

SIGNAL), attainment of the fixed arrow status [

] is

accompanied by a “beep”.

If gauge locking is enabled (

GAUGE LOCKING),

when a fixed arrow [

] is reached,

the gauge is automatically locked to prevent shifts during

application of the correction weight. To release and bring

the gauge back to the rest position, lower it to below 10”

diameter.

Use of the wheel balancer