English – CEMB USA ER100 User Manual

Page 77

77

use and maintenance manual Rev. 11-2011

ENGLISH

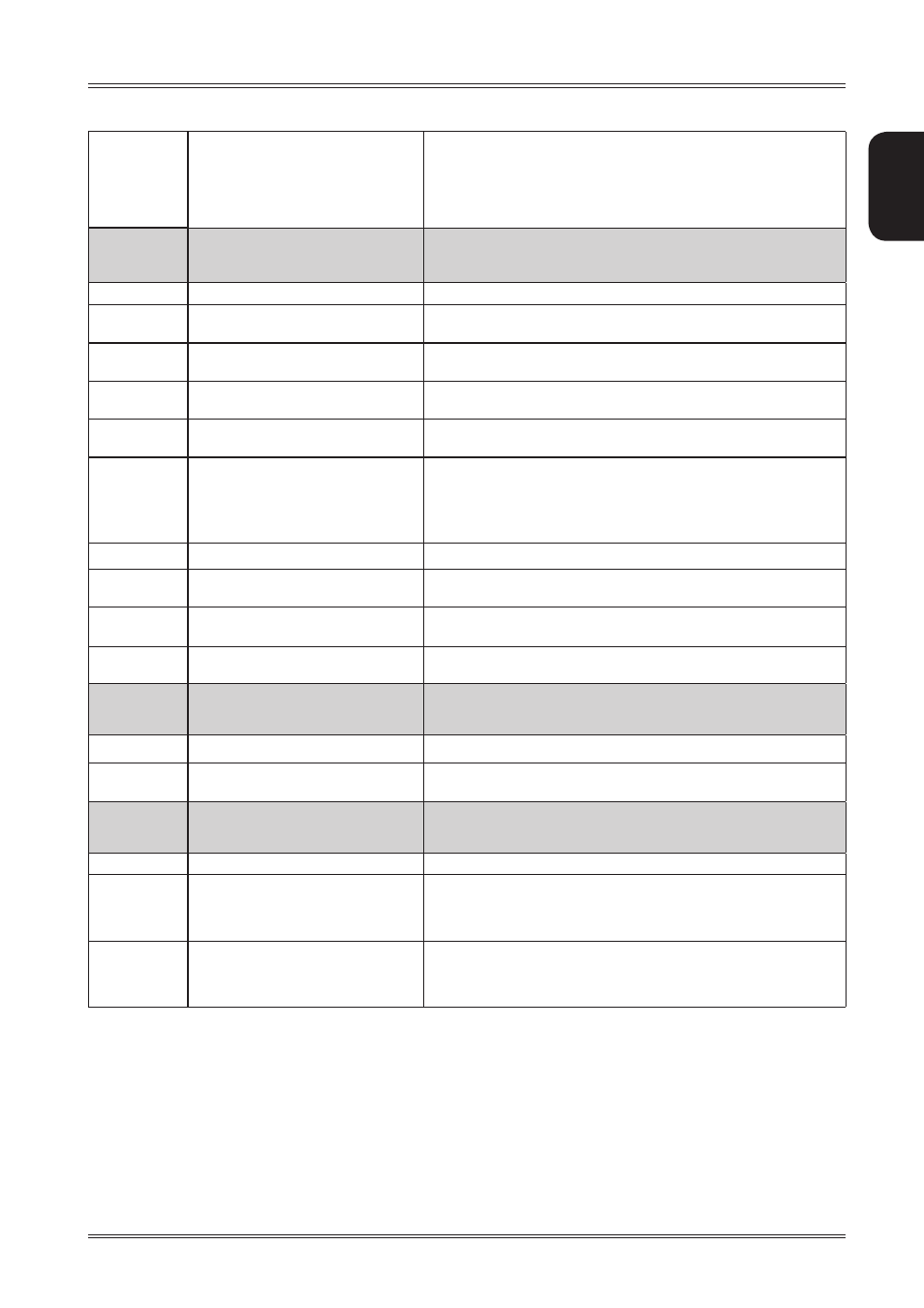

Err. 221/

Err. 222/

Err. 223/

Err. 224/

Err. 225

Internal laser read error

1. Check that the light spot is visible on the wheel to be measured.

2. Check that you have correctly mounted the wheel to be balanced.

3. Check that there are no objects other than the wheel in the laser

measuring range.

4. Repeat the dimension measurement.

HardwarE

ErrorS

caUSE

cHEckS

Err.2

Hardware error from acquisition board.

---

Code 21

Error. Guard open during measurement. 1. Repeat the measurement keeping the guard closed until the end of the

spin.

Code 22

STOP during a measuring cycle.

1. Repeat the measuring cycle avoiding to press the STOP button unless

for an emergency.

Code 23

Error. Lift position during the measuring

cycle.

1. Enable the measuring cycle only when the lift is in rest position.

2. Do not move the lift during the measuring cycle.

Code 24

Pneumatic spindle released during the

measuring cycle.

1. Lock the wheel before starting the measuring cycle.

2. Do not move the lift during the measuring cycle.

Code 25

Rotation start timeout.

1. Check that there are no obstructions to normal wheel rotation.

2. Use the self-diagnostics function to check the encoder.

3. Use the self-diagnostics function to check proper functioning of the

electromagnetic switch.

4. Check functioning of the power board relay

Code 26

Wheel braking timeout

1. Check functioning of the power board relay

Code 27

Inverse rotation.

1. Use the self-diagnostics function to check the encoder.

2. Check functioning of the power board relay

Code 28

Unbalance measurement timeout.

1. Repeat the unbalance measuring cycle.

2. Contact Technical Service.

Code 29

Eccentricity measurement timeout.

1. Repeat the eccentricity measuring cycle.

2. Contact Technical Service.

ErrorS

HardwarE

tYpE

caUSE

cHEckS

Err.3

Software error from acquisition board.

---

Code: all

Configuration parameter setting errors

from the PC to the computer board.

1. Turn the wheel balancing machine off and on again.

2. Contact Technical Service.

ErrorS

HardwarE

tYpE

caUSE

cHEckS

Err.128

Ethernet error.

---

Code: all

Communication errors via Ethernet

between the PC and the acquisition

board.

1. Turn the wheel balancing machine off and on again.

2. Check the Ethernet connection cables between the PC and the

acquisition board.

3. Replace the acquisition board.

Unbalance

incorrect with

back centring

cones

Wheel slipping on the adapter because

the BP system is at the end of travel or

because of incorrect fitting of the tyre

tie-rod

Mount the wheel in vertical position and push the sleeve up against the

wheel. If necessary, repeat locking/unlocking/locking and perform the

procedure again.

Diagnostics