1 runout, 1 when and why to use matching, For more information, refer to the paragraphs – CEMB USA ER100 User Manual

Page 42

42

use and maintenance manual Rev. 11-2011

ENGLISH

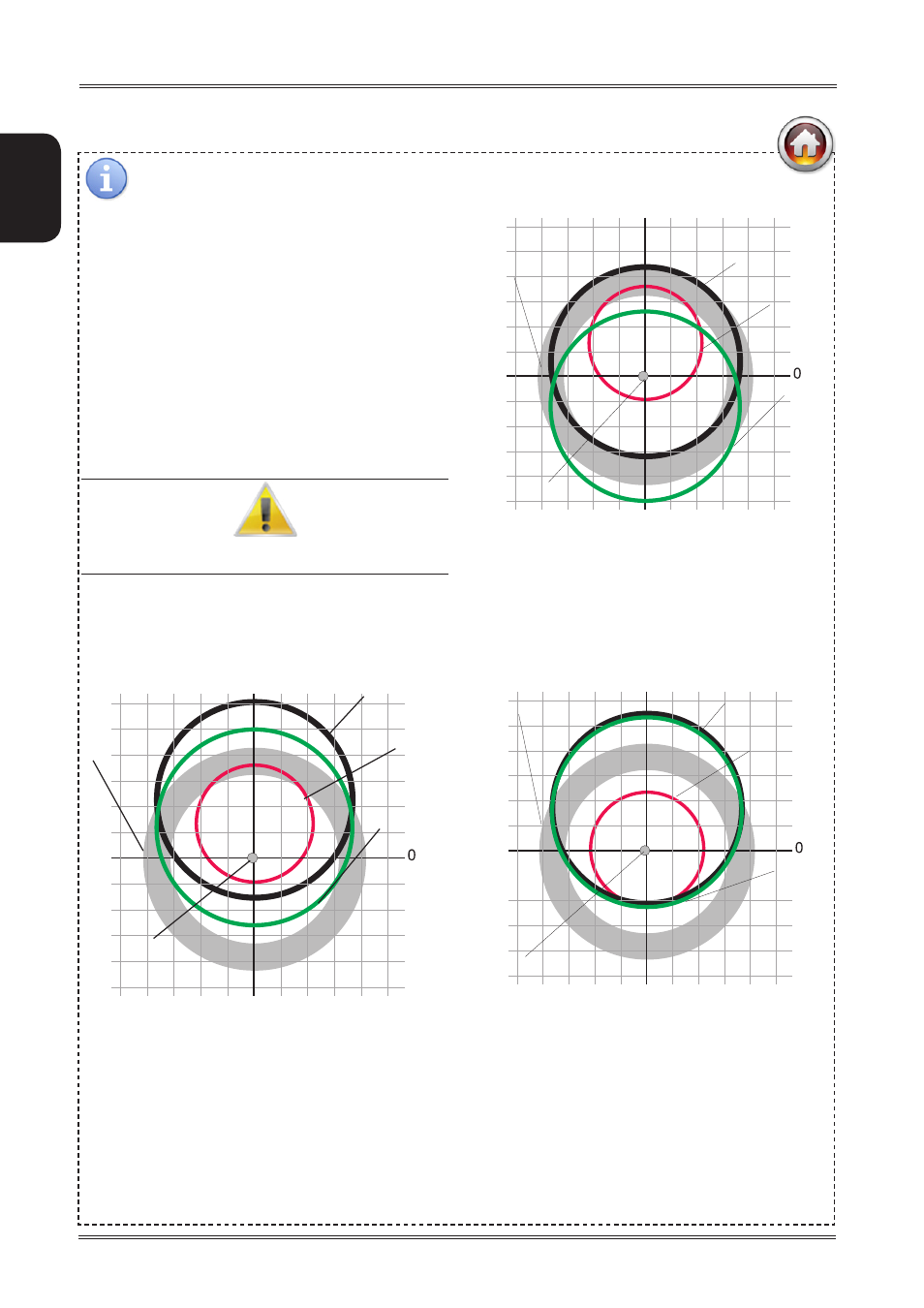

Tyre - 0.6 mm

Wheel + 0,3 mm

The eccentricity of the single elements is compensated.

The wheel is acceptable.

Example 3

Rim - 0 mm

Tyre + 1,2 mm

Wheel + 1.2 mm

The wheel eccentricity cannot be compensated by the rota-

tion because the rim is perfect!

SoLUtIoN: turn the tyre on the rim by 180°

rESULt: No improvement.

wheel

rim

tyre

rotation axis

wheel

rim

tyre

virtual wheel

rotation axis

wheel

rim

tyre

rotation axis

virtual wheel

virtual wheel

6.14.1 Runout

6.14.1.1 When and why TO USE MATCHING

The software associated with the eccentricity measure-

ment is a powerful tool to determine the need to perform

the relative rotation between the wheel and the rim in

order to reduce the eccentricity to within acceptable lim-

its. The criterion used is based on the fact that a rim with

acceptable tolerance, mounted with acceptable tyre, can

statistically generate an unacceptable total eccentricity

that can be improved by matching.

ER 100 is capable of automatically measuring the ec-

centricity of both the tyre and the rim from the inside.

The latter measurement generally corresponds to the rim

eccentricity in the tyre fitting area.

T

he

RIm

cAN

be

meAsuRed

moRe

AccuRATely

usING

The

specIfIc

pRoGRAm

WIThouT

The

TyRe

.

Example 1

Rim + 0.8 mm

Tyre + 0.6 mm

Wheel + 1.3 mm

The wheel eccentricityis excessive because an acceptable

rim or tyre has randomly been positioned in an “unfor-

tunate” position”.

SoLUtIoN: turn the tyre on the rim by 180°

rESULt: wheel eccentricity 0.3 – 0.4 mm (in tolerance)

Rim + 0.8 mm

Use of the wheel balancing machine