Can/j1939 interface – C.E. Niehoff & Co. N1387-1/EPM Troubleshooting Guides User Manual

Page 4

Page 4

TG0019A

Section 3: CAN/J1939 Diagnostics

CAN/J1939 Interface

DESCRIPTION AND OPERATION

The EPM and the CEN N3225 digital regulator are compatible with the

SAE J1939 communications standard for vehicle networking.

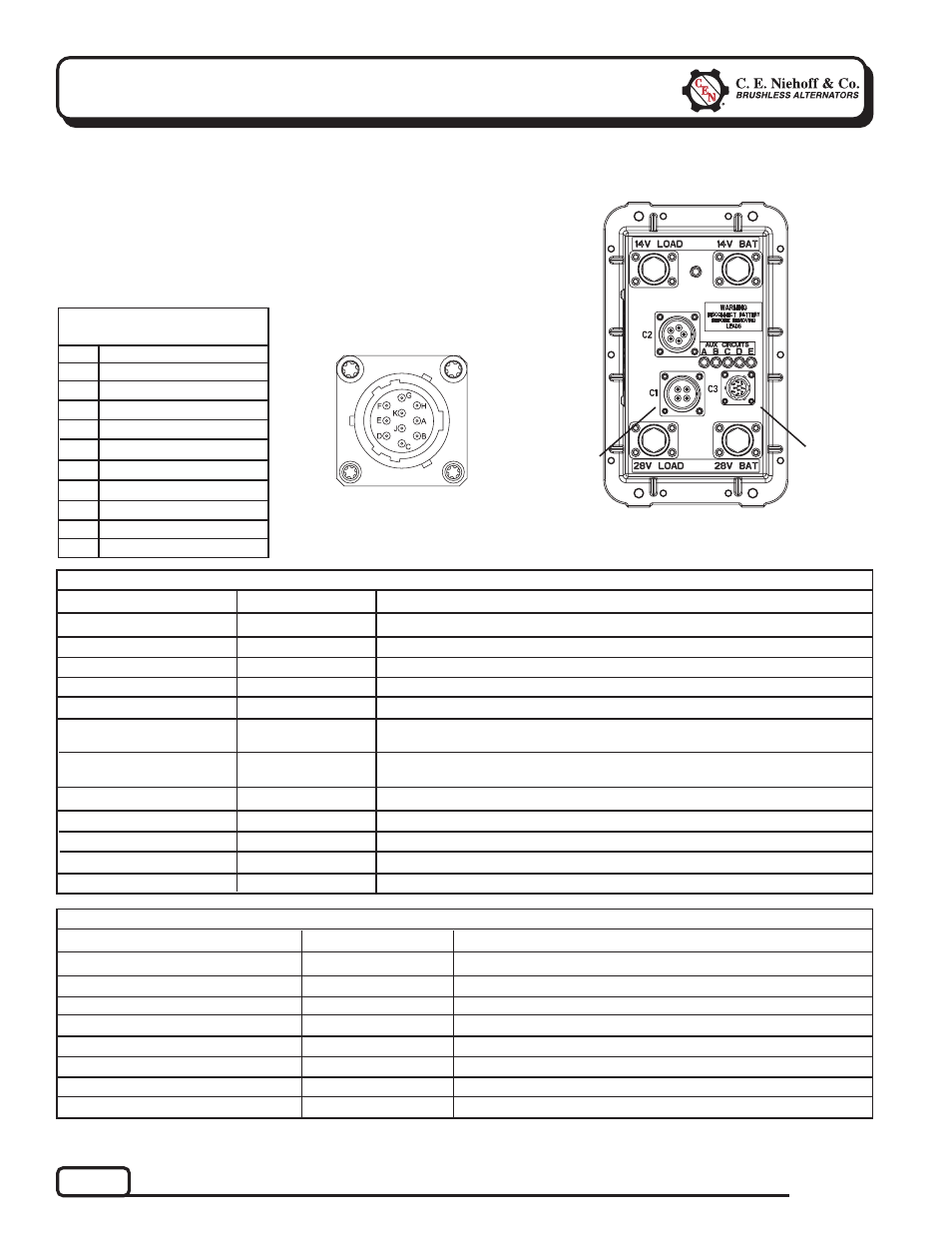

CEN uses MIL-STD connector MS3112E12-10P to interface between the

EPM/N3225 and the DPA adapter used to monitor the broadcast

messages on the CAN bus line. The readouts of these messages are

shown in Table 2 for the EPM and Table 3 for the regulator.

Pin

Identification

TABLE 1 – J1939 Connector

Circuit Identification

A

B

C

D

E

F

G

H

J

K

CAN High

CAN Low

CAN Shield

Ground

Restricted use

Restricted use

Restricted use

unused

unused

+28V power

Figure 4 – EPM Electric Power Manager

T T T T T

J1939

Connector

Under Cap

T

T

T

T

T

EPM

Connector

to N3225

Regulator

EPM Readout

Expected Reading

TABLE 2 – EPM/J1939 Readout Diagnostics (With Engine Running)

Load Voltage 28 V System

Load Voltage 14 V System

Alternator Speed

Battery Voltage 28 V System

Battery Voltage 14 V System

EPM Temperature

Charging and Discharging

Current of 28 V Battery

Batt Charging 28 V LED

Batt Charging 14 V LED

Main Switches On

Cranking Detected

Emergency Flasher Detected

Figure 3 – J1939

Connector Pins

27–29 V

13.5–14.5 V

1200 to 6000 RPM

27–29 V

13.5–14.5 V

–50ºF (–46ºC) to

200ºF (93ºC)

10 A (varies according

to battery condition)

OK

OK

OK

OK

OK

Action If Expected Reading Not Achieved

See Chart 1, page 7.

See Chart 2, page 8.

Check drive belt and charging system connection.

See Chart 1, page 7.

See Chart 2, page 8.

Check connections to EPM.

Observe current charges with battery and ignition on and then off.

See Chart 1, page 7.

See Chart 2, page 8.

Verify “Battery Connect” indicator is lit AMBER.

See Chart 5, page 11.

Check bulbs on flashers or ICC to battery.

Regulator Readout

Expected Reading

TABLE 3 – N3225 Regulator/J1939 Readout Diagnostics

Alternator Output Voltage 28 V System

Alternator Output Voltage 14 V System

Alternator Speed

Alternator Temperature

Battery Voltage 28 V System

Battery Voltage 14 V System

Alternator Output Capacity

Charging System Status

27–29 V

13.5–14.5 V

1200 to 6000 RPM

Less than 260º F/127ºC

27–29 V

13.5–14.5 V

0–100%

OK

Action If Expected Reading Not Achieved

See Chart 1, page 7.

See Chart 2, page 8.

Check drive belt and chg system connection.

Decrease load on alternator. See Chart 4, page 9.

See Chart 1, page 7.

See Chart 2, page 8.

Varies with load.

See Chart 1, page 7, or Chart 2, page 8.