C.E. Niehoff & Co. C540 Alternator Installation User Manual

C.E. Niehoff & Co. Hardware

II176A

Page 1 of 2

C540 Alternator

with Regulator

and External Rectifi er

Installation Instructions

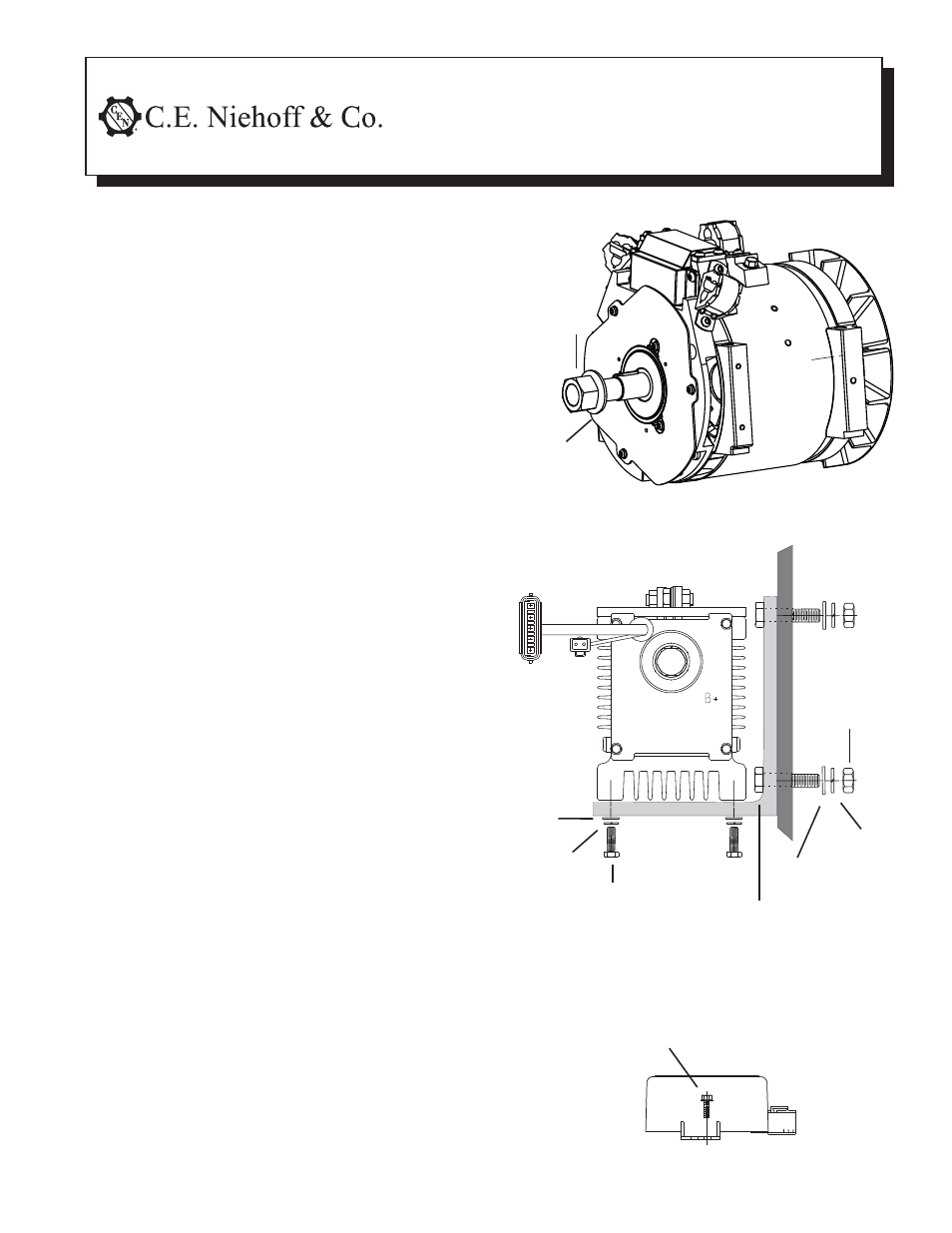

C540 Alternator

1. Install alternator on pad mount per vehicle manu-

facturer’s instructions, including hardware specifi-

cations and torque.

2. Units are shipped with shaft collar, Belleville

washer and nut. Remove and discard shaft collar.

Install pulley and furnished Belleville washer.

Torque nut to 135 Nm/ 100 lb. ft.

External Rectifier and Bracket

1. Mounting location of rectifier and bracket should

provide proper cooling and protect rectifier from

direct water, road debris, or chemicals.

Rectifier can be mounted up to 6 feet away from

alternator. Harnesses cannot be strung together

to create different lengths.

2. Use hardened washers between aluminum

surfaces and bolt heads and nuts. Bracket

mounting bolts must have minimum .50 in.

thread engagement. See Figure 2 for torque

values.

3. Use a suitable adhesive such as Loctite

®

222

or equivalent on screws. Follow manufacturer’s

instructions.

Figure 1 - C540 Alternator Installation

Figure 2 - Rectifi er and Bracket Installation

Locknut

(4 places) –

torque to

54 Nm/40 lb.ft.

Lockwasher

Flat washer

11mm/0.44 in.

Mounting bolt - grade

5 or better

.3750-16 UNC-2B Mounting bolt

grade 5 or better–

torque to 27 Nm/20 lb.ft.

Lockwasher

Flat washer

Nut–

torque to

135 Nm/100 lb.ft.

Belleville

washer

Regulator

1. Mounting location of regulator must provide

protection from water, road debris, or chemicals.

Regulator can be located up to 18 inches away

from the rectifier. If extension harness CEN

A9-448 is added, the regulator can be moved an

additional 43 in. away.

2. See Figure 3 for torque values.

Figure 3 - Regulator Installation

#10-32 x .62 fl ange lock screw (4 places) -

torque to 8.5 Nm/75 lb. in.