C.E. Niehoff & Co. C180etc and C181etc Installation User Manual

C.E. Niehoff & Co. Hardware

II162A

Page 1 of 4

C180-1 Alternator

w/ A8-206 Rectifi er-Regulator

C180-2 Alternator

w/ A8-207 Rectifi er-Regulator

C181-1 Alternator

w/ A8-208 Rectifi er-Regulator

C180/C181 Alternators

Installation Instructions

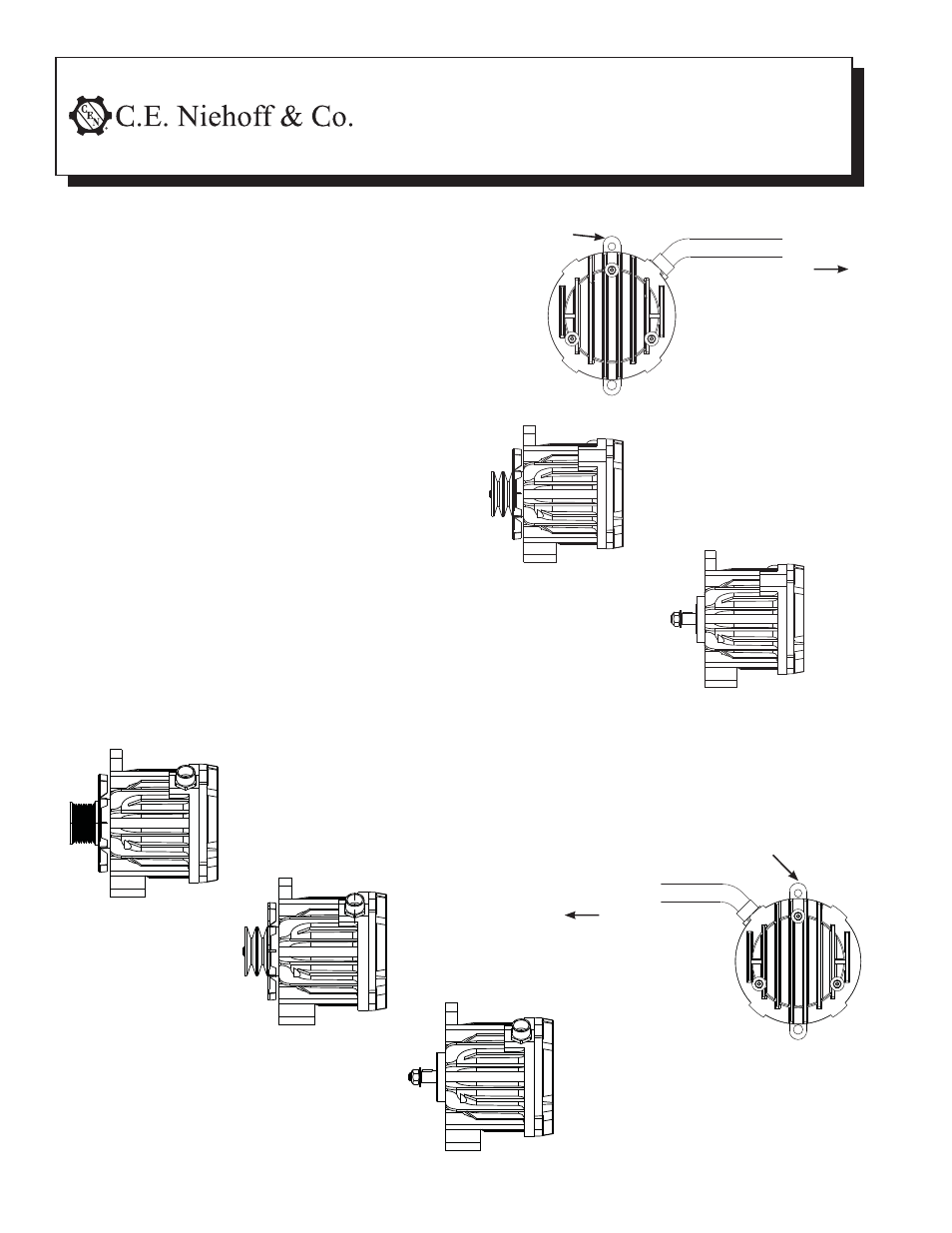

1. Install alternator with cover oriented in a position

that allows best vertical air flow through fins on

anti-drive end. See Figure 1 and 2:

a. C180-1, C180-2, and C181-1 units are shipped

with pulley/fan, flat washer, and nut installed.

b. C180 and C181 units are shipped with shaft

collar, flat washer, and nut. Remove and

discard shaft collar. Install pulley/fan and

furnished flat washer. Torque furnished nut to

68 Nm/50 lb. ft.

c. Use Grade 5 flange bolt and locking type flange

nuts to mount alternator. Self-locking type

screw is required to clamp up belt adjusting

bracket. Tighten the adjusting bracket before

tightening alternator mounting bolts. Torque

12mm x 1.75 mounting bolts to 50 Nm/ 37 lb. ft.

d. Follow vehicle manufacturer’s recommenda-

tions for belt tension.

2. Connect alternator and rectifier/regulator:

• C180-1—see page 2

• C180-2—see page 3

• C181-1—see page 4

• C180 and C181 alternators are replacements for

their corresponding dashed numbered alterna-

tors. Follow appropriate instructions listed above.

Figure 2 - C180-2/C180-1/C180 Alternator Details

Mounting lugs (2)

C180

C180-1

C180-2

Figure 1 - C181-1/C181 Alternator Details

C181

C181-1

Mounting lugs (2)

To rectifier-regulator

To rectifier-regulator