Caution – C.E. Niehoff & Co. N1304-1 to N1380-2: N7359-1 Conversion Kit Instructions User Manual

Page 3

Page 3

II0063A

CAUTION

10. Remove two top nuts on B+ stud and discard

one nut. Install output lead and remaining nut

on B+ stud and tighten firmly enough to hold

output lead on stud.

Out put terminal may

be damaged if nut is

overtightened.

11. Connect stator leads and phase lead to proper

stator terminals as shown in Figure 2. Torque

hardware to 3.4 Nm/30 lb. in.

12. Coat stator terminals and terminal block and

B+ stud terminal inside control unit with Dow

Corning

®3

3140 RTV coating or equivalent. Do

not use coating containing acetic acid (vinegar

smell) on electrical components.

13. Install new control unit cover on control unit

with tab on top facing out. Use a suitable adhe-

sive, such as Loctite

®

222 on new hardware.

Follow manufacturer’s instructions. Torque

screws to 2-2.25 Nm/18-20 lb. in.

14. Remove and discard two existing screws on top

of control unit.

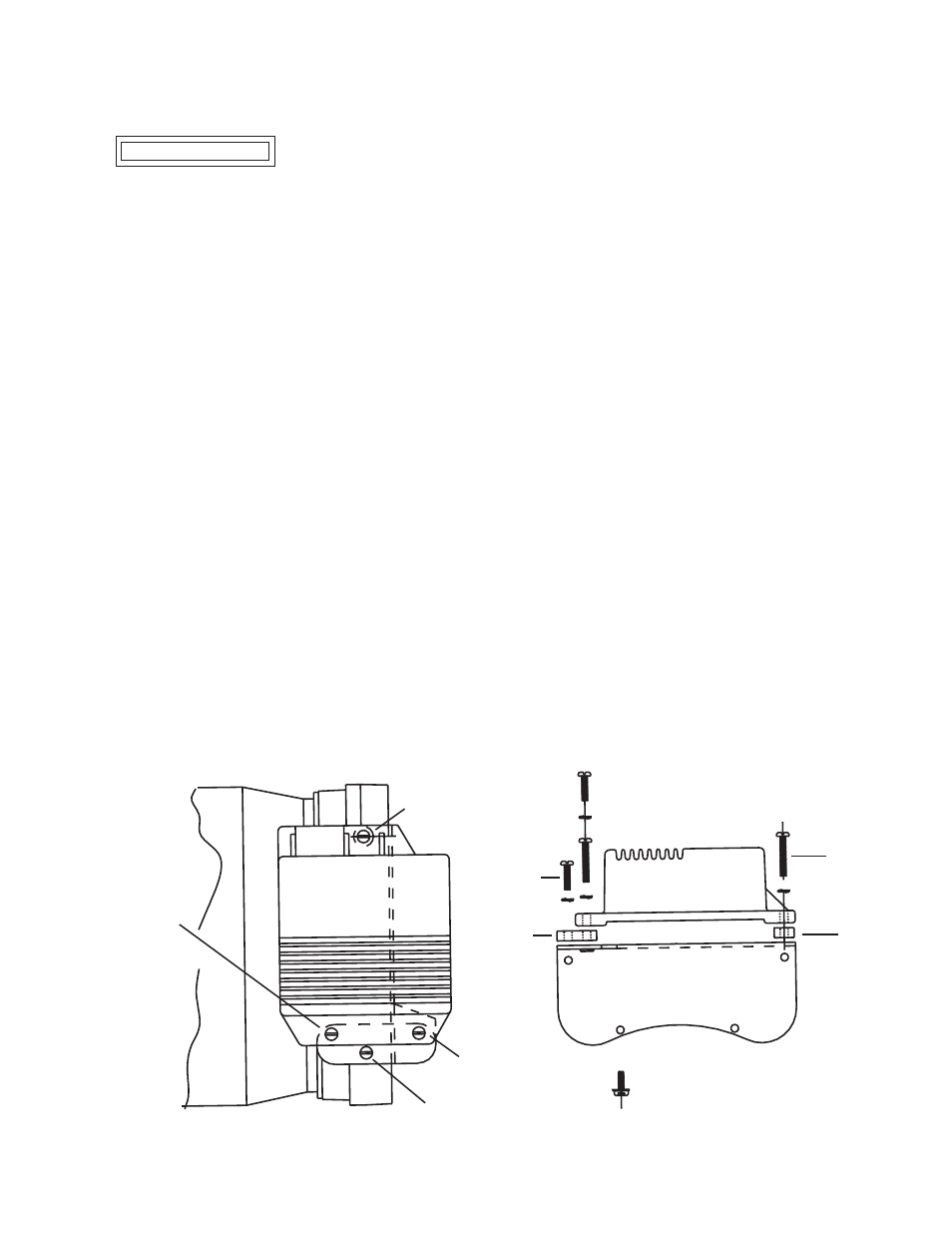

15. Place bracket, spacer, and regulator on top of

control unit as shown in Figure 5.

16. Use a suitable adhesive, such as Loctite

®

222 on

new hardware. Follow manufacturer’s instruc-

tions. Loosely install (see Figure 5):

a. one long screw and washer in regulator

mounting hole above spacer.

b. remaining long screw and washer in front

regulator mounting hole above bracket.

c. one short screw and washer in rear regulator

mounting hole above bracket.

d. remaining short screw and washer in

bracket.

17. Torque screws in a-b-c-d order listed in step 16

to 2-2.25 Nm/18-20 lb. in.

18. Place ADE rotor on shaft. Align scribe mark.

Loosely install all nuts and washers except for

the nut for the marked hole. Before securing

nuts, make sure scribe mark in last hole is

aligned. Then secure all nuts. On all screws, use

a suitable adhesive, such as Loctite

®

222.

Follow manufacturer’s instructions.Torque to

3.4 Nm/30 lb. in.

19. Align scribed marks, then set ADE housing

assembly in position on shell. If bearing re-

mained in housing, use CEN A10–109 bearing

tool or equivalent placed on bearing inner race.

Press on bearing and guide ADE housing on

shell. Rotate shaft to make sure bearing moves

freely.

20. Install existing locknuts on through-studs. Use

a suitable adhesive, such as Loctite

®

222.

Follow manufacturer’s instructions. Torque

locknuts to 2-2.25 Nm/18-20 lb. in.

21. Press fan assembly into bore of ADE housing.

Fasten with existing hardware and torque to

67.8 Nm/50 lb. ft.

22. Install pulley bushing on drive end shaft with

short hub facing bearing.

23. Install Woodruff key in slot in shaft.

24. Install pulley on shaft. Torque to 162.7 Nm/

120 lb. ft.

25. Plug regulator harness plug into regulator

receptacle in housing.

Test unit on bench to verify proper operation

after assembling.

TTTTT

Long

screw

Figure 5—New Regulator and Bracket Assembly

TTTTT

Short

screw

TTTTT

Bracket

TTTTT

Spacer

Long screw -

step 16a

T T T T T

Long screw -

step 16b

T T T T T

Short screw -

step 16c

T

T

T

TT

Short screw -

step 16d

T T T T T