Assembly, Caution – C.E. Niehoff & Co. N1304-1 to N1380-2: N7359-1 Conversion Kit Instructions User Manual

Page 2

II0063A

Page 2

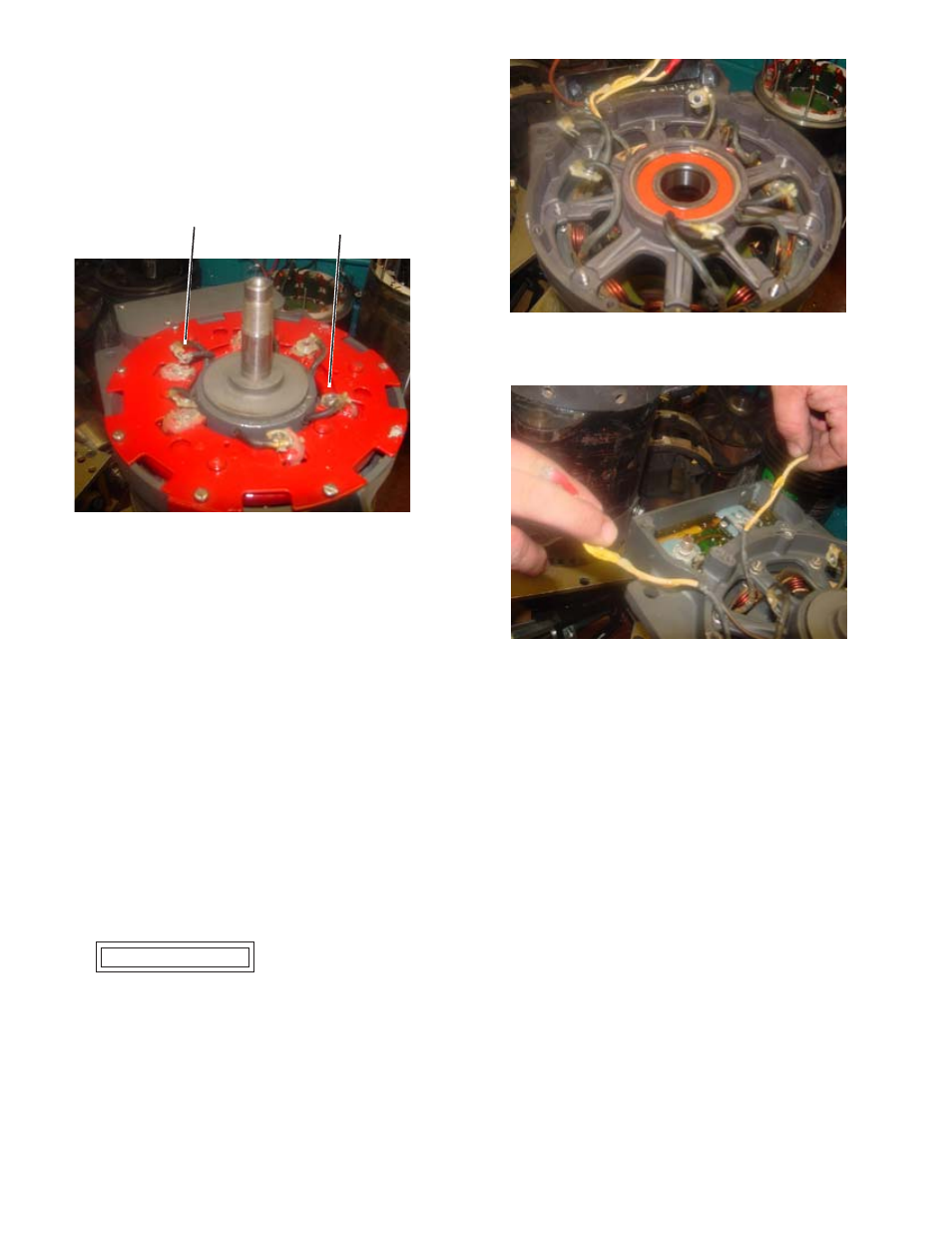

10. Remove and save hardware holding stator leads

and phase lead (attached to stator lead (at 10:00

position) to heat sink assembly. See Figure 2.

Clean coating material from leads. Check termi-

nals for rust or corrosion and clean with wire

brush if necessary.

11. Remove and save heat sink hardware (including

ground bolt and lockwasher on tab on side of

housing) and heat sink assembly.

12. Remove and save drive end housing hardware.

13. Remove drive end housing from shell.

14. Press shaft out of bearing in drive end housing.

Discard drive end housing and bearing. Save

shaft core/drive end rotor assembly.

Assembly

1. New drive end housing has bearing and retaining

rings installed at factory. Using CEN A10–109

bearing tool or equivalent placed on bearing

inner race, press shaft into bearing in DE

housing. Rotate shaft to make sure bearing

moves freely.

2.

Support shell/field coil/stator assembly on

blocks while installing DE housing and shaft.

Do not damage stator

windings or through-studs

while assembling DE hous-

ing and shell. Make sure

support is tall enough so

that shaft clears bench.

3.

Align scribed marks, then set housing assembly

in position. Pull stator leads and field coil leads

through vent holes in assembly. See Figures 3

and 4. Securely mate housing to shell. Rotate

shaft to make sure rotor does not interfere with

stator leads or field coil leads.

Figure 2—Phase Lead and Stator Leads Connections

T

T

T

T

T

T

T

T

T

T

Stator lead

(one of six)

T

T

T

T

T

T

T

T

T

T

Phase lead

CAUTION

4.

Install existing locknuts on through-studs. Use

a suitable adhesive, such as Loctite

®

222.

Follow manufacturer’s instructions. Torque

locknuts to 2-2.25 Nm/18-20 lb. in.

5.

Guide field coil leads through channel in hous-

ing. See Figure 2. Attach field coil leads to

terminal block. See Figure 1 for correct loca-

tions. Tighten screws just enough to firmly hold

leads in terminal block. Wire-tie field coil leads

together inside channel.

6.

Install heat sink assembly, guiding stator leads

and phase lead through center opening to their

respective positions. See Figure 2.

7.

Install existing hardware to hold heat sink in

position. Use a suitable adhesive, such as

Loctite

®

222. Follow manufacturer’s instruc-

tions. Torque screws to 2-2.25 Nm/18-20 lb. in.

8.

Loosely install ground bolt and lockwasher in

tab on side of heat sink into housing.

9.

Install ground lead in terminal block. Tighten

screw just enough to firmly hold leads in termi-

nal block. See Figure 1 for position.

Figure 3—Phase Leads and Field Coil Leads

Figure 4—Field Coil Leads