3 troubleshooting guide – PA Industries Edge Sequential Servo Roll Feed SRF-100/125/200/300/400/500/600 - Operation Manual User Manual

Page 25

ULTRA EDGE SEQUENTIAL 6

/05/2002

25

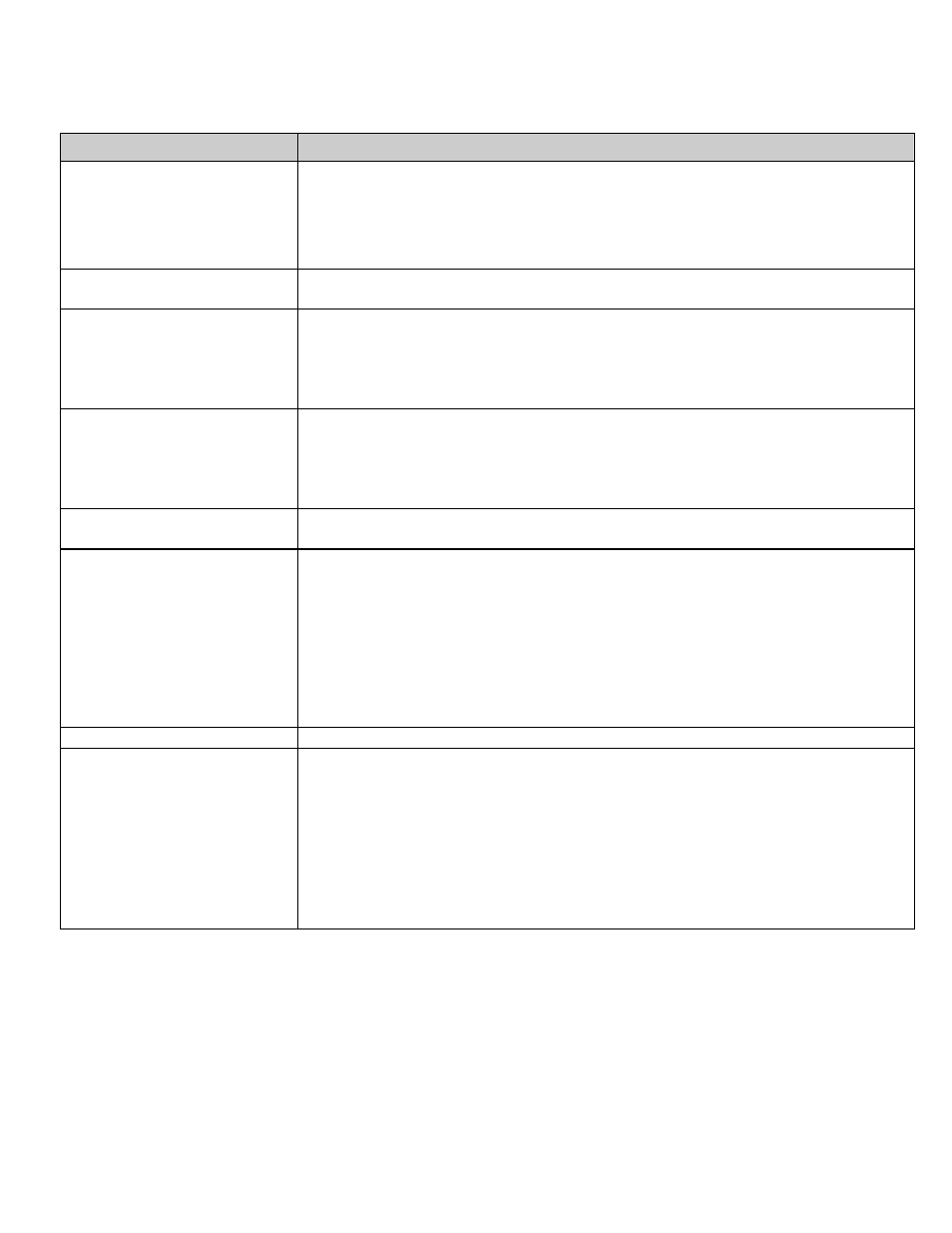

5.3 TROUBLESHOOTING GUIDE

The chart that follows contains the most frequently encountered issues.

Symptom

Cause or Remedy

No power indication when

Power On button is pressed

1. Check the main power supply for proper voltage.

2. Check the supply circuit breakers.

3. Verify that the main disconnect switch is on.

4. Verify that the E-Stop is not engaged (E-Stop Loop closed.)

5. Check the bulb in Power On push button.

No display on power up

6. Check the cabling connection between display and the servo drive.

7. Check 5 VDC power supply.

Feed will not jog

8. Check if IN POSITION indicator is off. Check parameters. Check drive for

Error Codes.

9. Check

the

FAULT in display i.e. DRIVE FAULT # ABC. Check for Error

descriptions. See Section 5.2 of the “Ultra 5000 Intelligent Positioning Drives”

Installation Manual.

Power On indicator is lit. Feed

will not operate.

10. Check that the IN POSITION indicator is lit. If not, check parameters.

11. Check that the Error message is in the Display. If so, check error description in

Section 5.4

12. Press the Power On button, release the Power On button, and then try to jog

feeder.

Feed will not accept new “Feed

Length” or other parameters

13. Make sure that the feed is not in “Auto” Mode.

14. Reset the Feed.

Inaccurate feeding

15. Adjust the rolls for the correct material thickness; the tip of the roll release lever

must have a small amount of play/wobble – approx. 1/16’’.

16. Adjust the spring pressure (Do not bottom springs. Catastrophic damage can

occur.)

17. Confirm if the rolls are slipping on the strip. Remove oil from the feed rolls,

reduce acceleration, check the tool for binding/slugs, etc.

18. Adjust the upstream equipment if the upstream equipment not providing

adequate/consistent free loop.

19. Check the roll release for the proper settings

Feed runs backwards

20. Verify that the direction parameter has been set properly (CW or CCW).

Drive Fault

This is a generic display prompt indicating a fault on the Servo Drive.

21. Look at the diagnostic display on the Servo Drive. The cause of the fault can be

determined by reading the Error Code.

22. Refer to Sections 5.4. This fault condition can be caused by any one of the errors

in the lists.

23. Check the Error Code first, then reset the Servo Drive by turning the power off,

waiting 10 seconds, and then powering the Servo Drive back on.

24. Verify that the fault will not reset. Call the factory for assistance.

If the problem you are having does not appear in the above chart, or does appear in the chart, and you have questions

about it, call the P/A Service Department for assistance. Please have your Model Number and Serial Number ready.

However, it is advisable to check the basics before calling to be sure the problem is not something simple that may

have been overlooked.