Setting the torque switching, 1 setting, 2 checking the torque switches – AUMA Electric multi-turn actuators SA 07.1 - 16.1_SAR 07.1 - 16.1 MATIC AM 01.1 - 02.1 User Manual

Page 25: Torque setting 25, Tripping torque 25

14.

Setting the torque switching

14.1 Setting

.

The set torque must suit the valve!

.

This setting must only be changed with the consent of the

valve manufacturer!

.

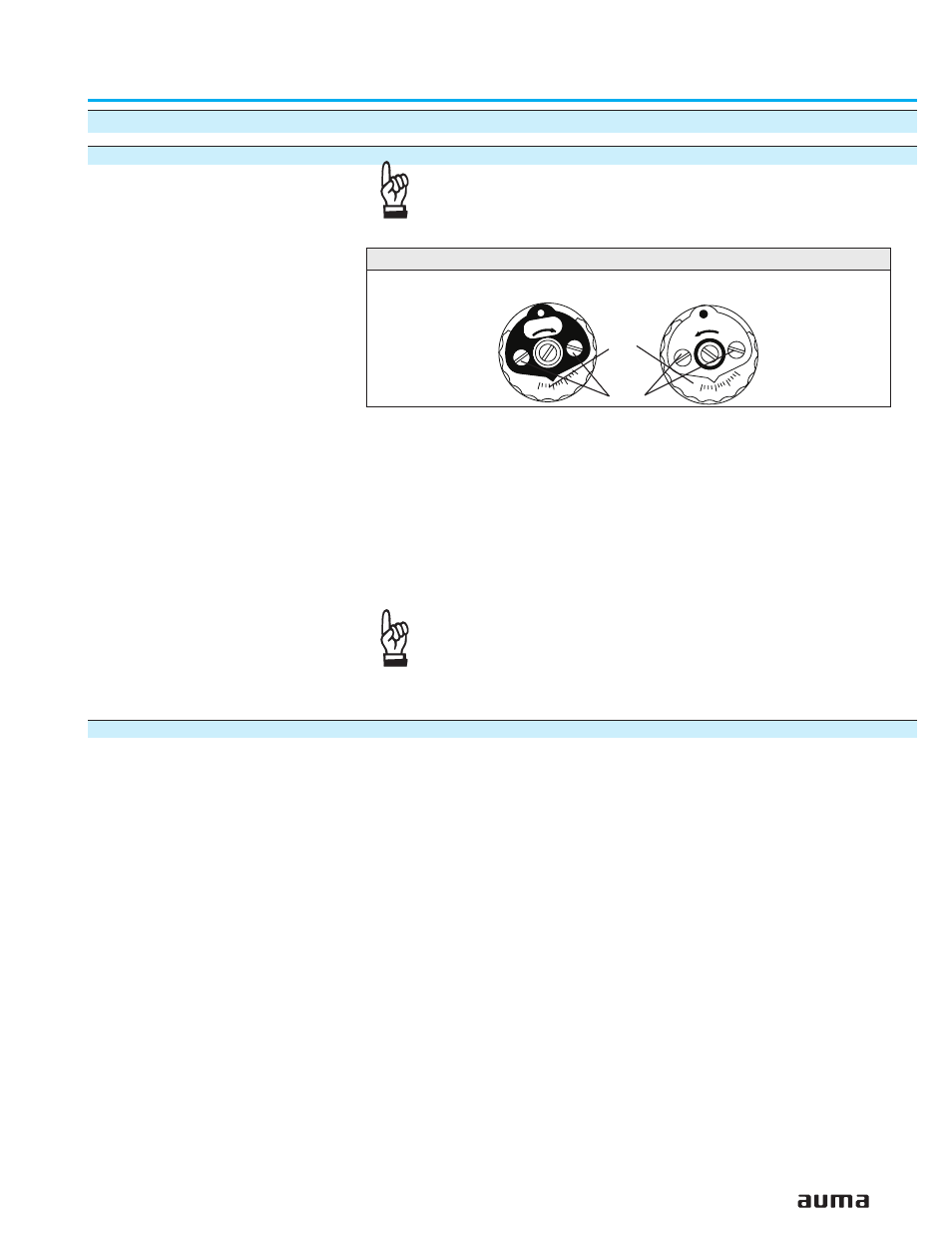

Loosen both lock screws O at the torque dial (figure Q).

.

Turn torque dial P to set it to the required torque.

Example:

Figure Q shows the following setting:

35 ft lbs for direction CLOSE

25 ft lbs for direction OPEN

.

Tighten lock screws O again

.

The torque switches can also be operated in manual

operation.

.

The torque switching acts as overload protection over full

travel, also when stopping in the end positions by limit switch-

ing.

14.2 Checking the torque switches

The red test buttons T and P (figure P-1) are used for manual operation of the

torque switches:

.

Turning T in direction of the arrow TSC (DSR) triggers torque switch

CLOSED.

The yellow indication light (fault) on the local controls is illuminated.

.

Turning P in direction of the arrow TSO (DÖL) triggers torque switch OPEN.

The yellow indication light (fault) on the local controls is illuminated.

.

If a DUO limit switching (optional) is installed in the actuator, the intermediate

position switches will be operated at the same time.

.

After checking the switches, the fault (yellow indication light) has to be reset

using the OPEN or CLOSE push buttons of the local controls for operation in

the opposite direction.

25

Multi-turn actuators SA 07.1 – SA 30.1/ SAR 07.1 – SAR 30.1

Operation instructions

with actuator controls AUMA MATIC AM 01.1 / AM 02.1

Ft. Lbs

Ft. Lbs

15

35

45

25

45

25

15

35

Figure Q: Torque switching heads

Setting CLOSED

Setting OPEN

O

P