Franklin Fueling Systems Probe Installation Quick Reference User Manual

Probe, Safety, Installation

Probe

Installation

PRODUCT

Ullage

Install Probe

1/4" (6.4 mm) Above

Bottom of Tank

Water Float

Product

Float

6.0" (152 mm) Minimum

14" (356 mm) Minimum

Manhole Cover

8.0" (203 mm)

Reference

5"(127 mm)

Minimum

N.T.S.

Spacer

Warning

Warning

Warning

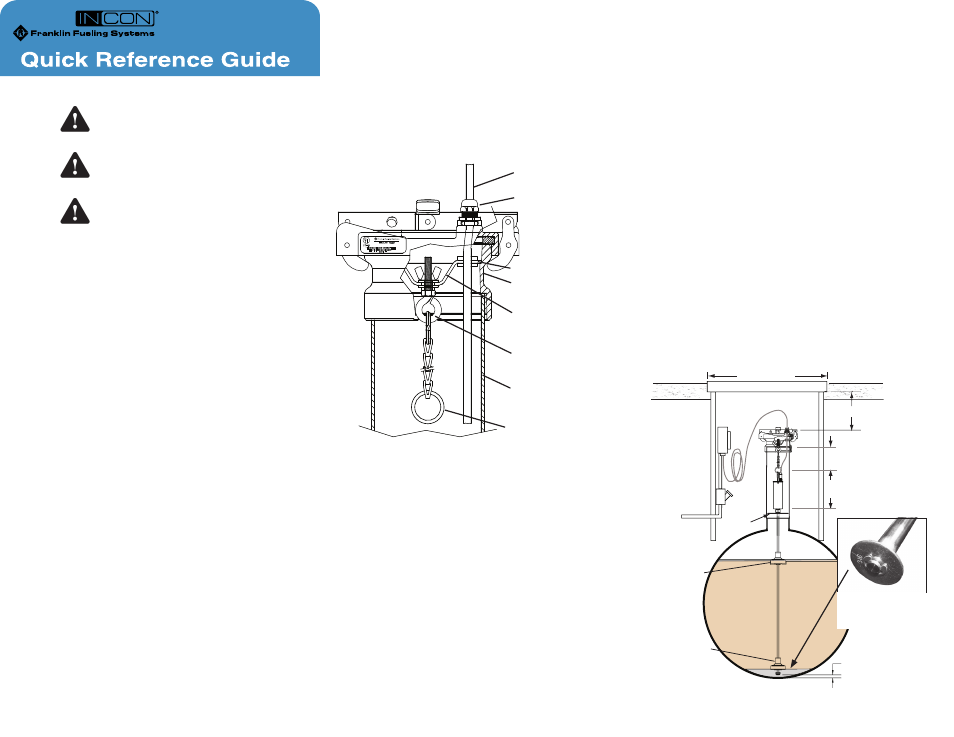

Suspended Probe Installation

Remove and Save

E-Clip and washer

to install floats

Split Ring

Safety

Always lock out and tag electrical

circuit breakers while installing or

servicing this equipment.

Follow all federal, state and local

laws governing the installation of

this product.

Always secure the work area from

moving vehicles.

Purpose of this Guide

The purpose of this guide is to show basic installation

information for magnetostrictive probes, floats and

installation kits offered by Franklin Fueling Systems.

For more detailed information, refer to manual

000-2081, TSP-LL2 Magnetostrictive Probe Installation.

This and other related manuals are available on the

web at www.franklinfueling.com –Service –Technical

Documentation–Fuel Management Systems.

Types of probes

• Level / Leak Detection

• Inventory-Specific

Probe Length

The probe model number indicates its length. The

model numbers are in the form TSP-LL2-xxx, where

xxx = the length of the probe shaft (not including probe

head) in inches. Consider riser height and overhead

clearance when selecting probe length.

For example, the TSP-LL2-101 is for 8’ (96") tanks.

Float Kits

Floats are available for 2", 3" and 4" risers, for gasoline

or diesel. (LPG and chemical floats also available).

Each float kit includes a product and water float. Order

one float set for each LL2 Mag probe.

• Product floats are white (clear)

• Gasoline water floats are red.

• Diesel water floats are blue

Probe Installation Kits

Installation kits are available for 2" and 4" risers with

either NPT or BSP threads. Kits for above-ground tank

probes and LPG probes are also available.

Mounting Suspended Probes

Leak Detection Probes

must be suspended ¼" above

the bottom of the tank using one of the appropriate

installation kits.

R

Riser Cap Adapter

Support Plate

Riser Pipe

Eyebolt

Probe Cable

Rubber Grommet

Suspended Probe Installation Detail (TSP-K4A shown)

Installation

1. Measure from the top of the riser pipe to the

bottom of the tank-record value in inches.

2. Measure the overall length of Probe.

3. Subtract the probe length from the distance

measured from the top of the riser pipe to

the bottom of the tank, and then add 1/2 inch

to this distance. This value is the

TOTAL

LENGTH OF THE CHAIN INCLUDING THE

SPLIT RING AND ADJUSTMENT EYEBOLT.

4. The suspension chain must be cut to the exact

length required.

5. Remove the split ring from the end of the chain

and cut the chain to the correct length.

6. Reattach the split ring to its end and measure

the total overall length to make certain that it is

within one half inch of correct value.

7. Apply pipe sealant to the male riser threads.

8. Screw the riser cap adapter into the top of the

riser pipe. Tighten to 20-25 ft-lbs.

9. Connect the probe to the split ring on the chain.

10. Carefully position the steel support plate

containing the rubber grommet and insulating

shoulder washer into the riser cap.

11. Guide the probe cable through the rubber

grommet.

12. Unscrew the adjusting eyebolt so the probe

just touches the bottom of the tank.

13. Turn the wing nut clockwise, 4 full turns (only).

This will raise the probe approximately ¼"

above the bottom of the tank.

14. Push the probe cable through the compression

fitting on the probe cap.

15. Install the probe cap on the riser cap adapter

such that the compression fitting is aligned with

the rubber grommet.

16. Tighten compression fitting to make a

watertight seal.

Compression Fitting