Electrical wiring – Franklin Fueling Systems TSP-MWS User Manual

Page 3

7. Turn power on to console to test sensor.

8. Test sensor (verify that an alarm is produced at

ATG console), if it does produce an alarm, seal

EYS seal fittings and electrical connectors with

epoxy.

9. Turn power off again if other devices are to be

installed (Repeat Step 3).

10. Install the TSP-MWS sensor in the well screen

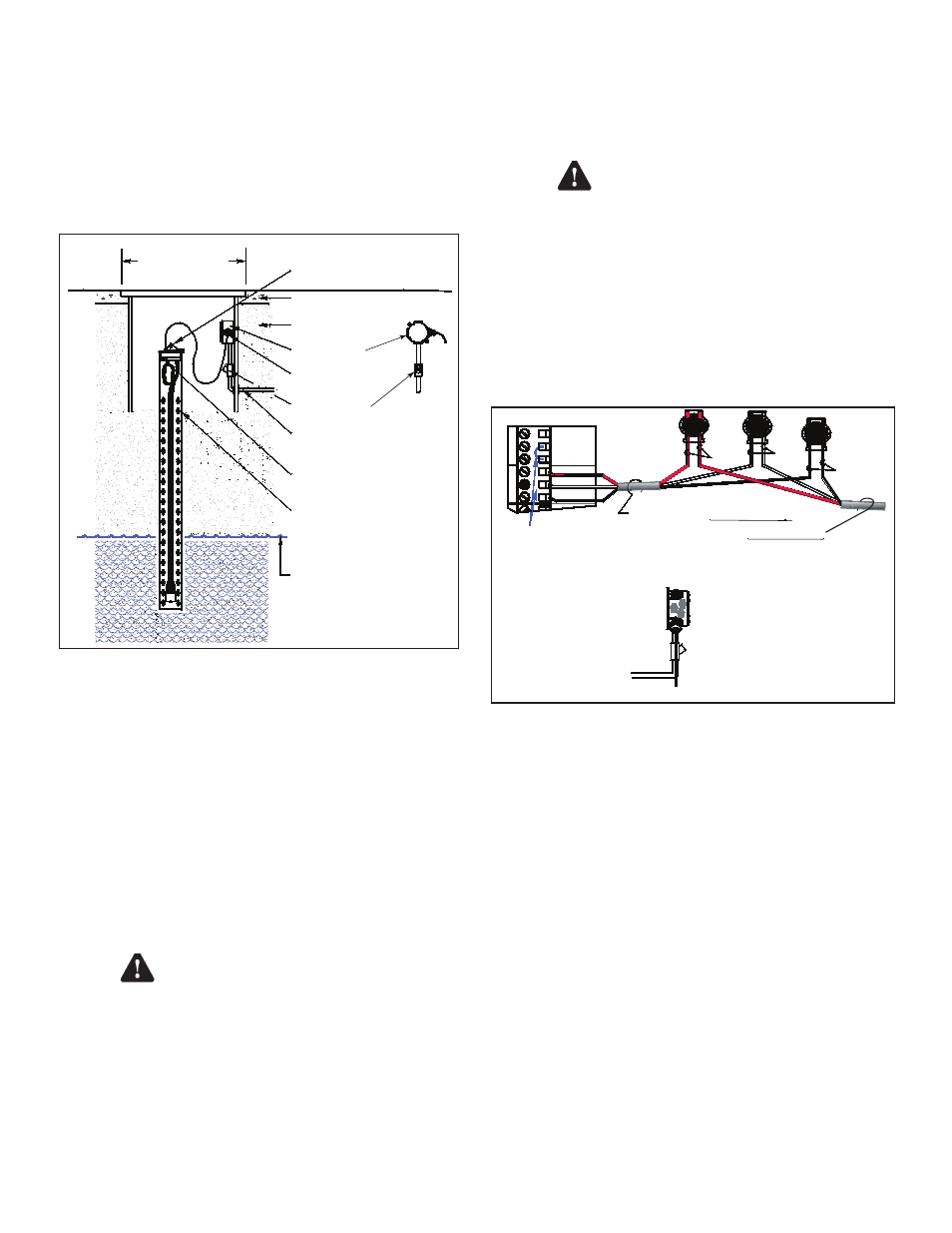

pipe and latch the riser cap (ref. Figure 1 & 2).

Cover for

14 inch (35.56 cm)

min. dia. manhole

Manhole

EYS seal fitting

½ or ¾ inch conduit

Loop extra

Sensor length

On retainer

Dry season groundwater level

4 inch (102 mm) pvc

monitoring well screen pipe

Concrete slab per NFPA 30

Weatherproof

Junction box

Compression

Fitting (cord grip)

Clean fill material

(Gravel typical)

TSP-MWS-XX

With riser cap

Figure 2: TSP-MWS Installation

11. Reinstall all safety covers and guards, junction

box gasket and covers – use pipe-dope to seal all

fitting threads.

12. Install the manhole cover.

13. Record the location where the sensor was

installed (Tank #,Sensor Channel #, and other

data) on the table on the back page of these

instructions.

14. Turn power on and program the ATG – Refer

to Sensors in the ATG Setup / Programming &

Installation manuals.

General Installation Notes

It is the installer’s responsibility to

comply with all applicable federal, state

and local codes. Failure to do so may

create an Environmental Hazard.

Plan your conduit routing. Dig trenches as necessary to

install conduit from each junction box to the Intrinsically

Safe (I.S.) knockouts at the ATG console. You must install

a weatherproof, electrical junction box inside each sump.

Access to sumps must be done so all entries are liquid-

proof (to keep product in the sump if a spill or leak occurs).

The junction box should be installed high on the sidewall to

prevent it from being submerged during heavy rains.

A junction box may be used inside of the building and used

as a I.S. pull box to combine several sensor cables. If this

is done, then only one I.S. conduit knockout may be used

at the console. Before pulling wires, mark them to avoid

confusion when connecting to the console.

Conduits must have EYS seal fittings

installed in accordance with NFPA

70 (National Electric Code) and NFPA

30A (Automotive and Marine Service

Station Code). Failure to seal conduits

in accordance with NFPA 30A, and

NFPA 70 could allow flammable vapors

to travel through the conduit in the

ATG console. An explosion could result

causing serious injury, property loss,

or death.

CAUTION Seal all threaded fittings and conduit threads to

produce a weatherproof seal during installation.

TO 3-WIRE SENSOR

3 WIRES/CABLE FROM CONSOLE

3-CONDUCTOR CABLE FROM SENSOR

S

E

N

S

O

R

N

IN(WHT)

Only remove the

jumper link between:

IN (wht) & GND (blk),

when a sensor channel is wired

Note: The PWR (red) terminal

is only used with 3-wire sensors

GND(BLK)

PWR(RED)

PWR(RED)

S

E

N

S

O

R

1

IN(WHT)

GND(BLK)

Insert the unstripped wires

fully into the self-sealing,

no-strip electrical connector.

Use slip-joint pliers and

seat the black portion to

make a good electrical connection

GND

(BLK)

PWR

(RED)

IN

(WHT)

Figure 3: Sensor Wiring

Electrical Wiring

Reference the ATG Installation Manual and see Figure 3

(above) for TSP-MWS sensor wiring details.

Caution

Warning

Caution

Warning

3