Overview, Testing the tsp -hls, Materials & data required – Franklin Fueling Systems TSP-HLS User Manual

Page 2: Installation sequence

Overview

The TSP ‑HLS is a standard sensor that is used to detect

a high liquid level condition within storage tanks (for Class

1, Division 1, Group D Hazardous Area / Environments

such as fuel storage tanks). The sensor is available in two

standard lengths: TSP‑HLS‑15 = 15 inch (381 mm) and

TSP‑HLS‑30 = 30 inch (762 mm). The sensor is supplied

with electrical connectors, 25 feet (7.5 meters) of attached

cable, and a cord‑grip fitting.

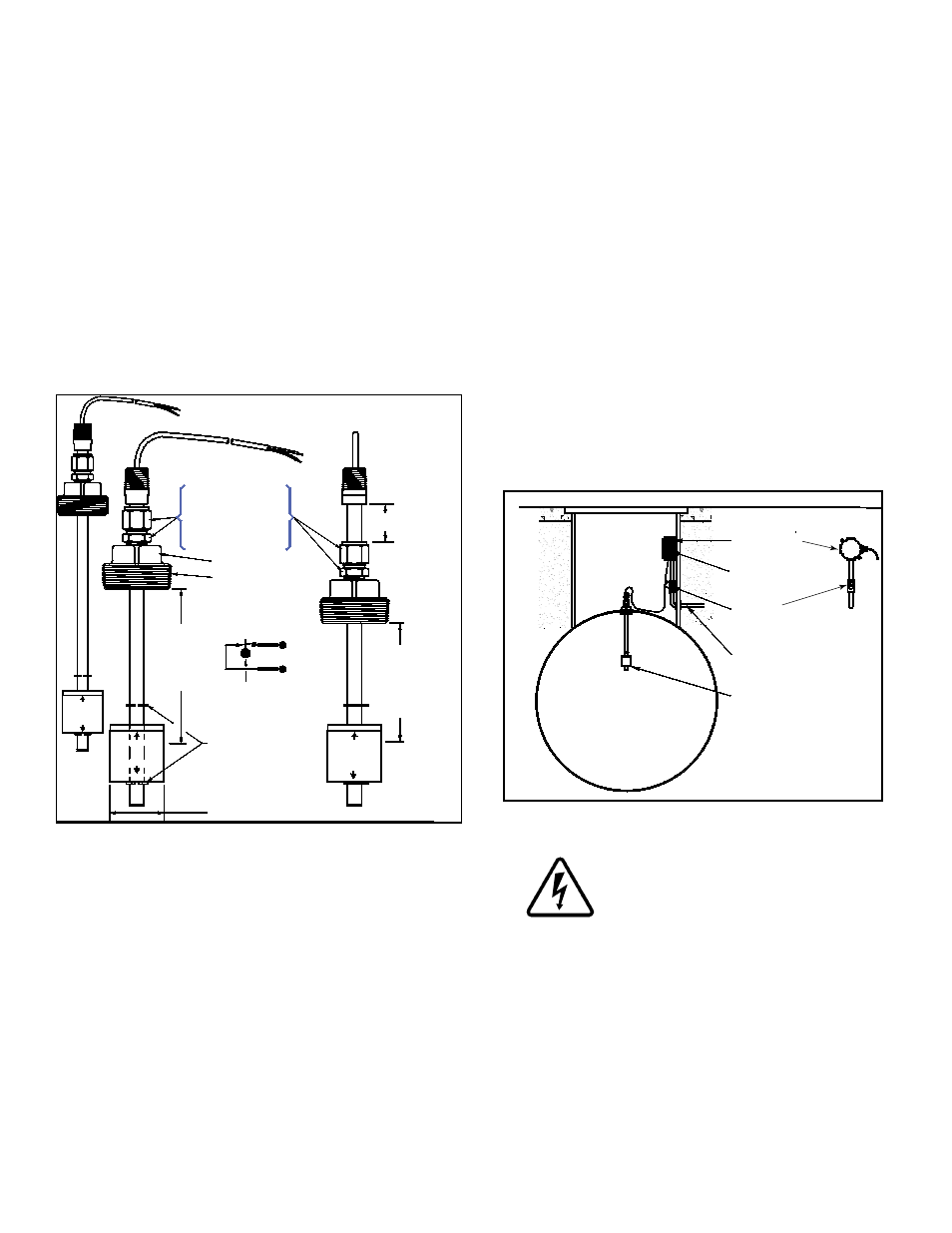

The

TSP-HLS sensor uses magnetic‑float / reed‑switch

technology for liquid detection. The wetted portion of

the sensor is constructed of stainless steel and nitrophyl

(float). When the float rises about ½ inch (12.5 mm), the

magnetically‑sensitive reed switch opens (see

Figure 1).

An open circuit is an alarm‑condition (at the intrinsically-

safe,

sensor interface terminals inside the Franklin Fueling

Systems ATG console).

1.86 inch (47.25 mm)

Dia. float

(Black)

Square (33.25 mm)

2 inch NPT fitting

Magnetic reed

float switch circuit

opens when float

moves up

Typical sensor

input interface

(Channel n):

(WHT)

(BLK)

TSP-HLS-XX

CLOSED

OPEN

Float retainer

C-clips

HIGH LEVEL SENSOR

(Standard Sensor)

TSP-HLS

7/8 inch (22.23 mm)

Swage locknuts to set

Actuation length (Float

height alarm setpoint)

adjusted length L

NC

C

GND

TSP-HLS-XX

OPEN

CLOSED

Adjusted

Length L

IN

(White)

C LOSED

OP

EN

Model number

value indicates

approximate

maximum

adjusted length

in inches

Model number

value minus (-)

length L = Float

height (high alarm

setpoint) in inches

Figure 1: TSP-HLS Dimensions and Setup

Testing the TSP -HLS

Rotate the sensor 180 degrees (float up) to cause an

alarm at the ATG console. Test the sensor for proper

operation on a yearly basis, or as required per local code.

Materials & Data Required

• Optional – TSP‑DB1 Epoxy Seal kit for no‑strip electrical

connectors – recommended for sites: within flood

zones, high groundwater tables, with poor drainage, or

when Junction Boxes are not used

1/2 or 3/4 inch NPT (National Pipe Thread, tapered),

•

Rigid Metal Conduit (RMC) or nonmetallic (PVC) conduit

if allowed by local code.

EYS Seal fittings and epoxy to fill the fitting after

•

operational testing is completed.

Weatherproof junction box, gasket, and cover, plus a

•

3/4 to 1/2 inch NPT reducing bushing

if 1/2 inch RMC is

used – see the ATG Installation Guide for recommended

electrical Junction Boxes

Wire: THHN, TFFN or THWN, 18 AWG, White & Black,

•

or Alpha Cable # 58411, 0.114” O.D. (2.9 mm) – 1,500

feet (457 meters) max. length If using nonmetallic (PVC)

conduit, Alpha cable 58411 must be used.

Slip joint pliers to seat the no‑strip, self‑sealing wire

•

connectors – connectors are supplied with the sensor

Standard adjustable or pipe wrench for a 2 inch square

•

fitting

U.L. classified thread sealant or pipe dope.

•

Tank Strapping Table (Tank Chart) to set the

•

High Level

Alarm

Two 7/8 inch (23 mm) hex wrenches to adjust

•

FLOAT

HeigHT.

installation Sequence:

1. Install manhole.

2. Install conduit, EYS fittings, and weatherproof

junction box

Tank

Eys seal

Fitting

½ or ¾ inch conduit

TSP-HLS

Sensor

Weatherproof

Junction box

Compression

Fitting

(Cord grip)

Figure 2: TSP-HLS Installation

3. Turn off power.

eLeCTRiCAL DANgeR Avoid electrical

shock hazards: ensure all power

going to the ATg console is turned off,

tagged, and locked-out at the power

panel before doing any maintenance or

installation work at the ATg console

4. Pull the sensor cables through the cord grip fitting

at the junction box. Leave enough cable to allow

installation of the sensor in the tank: the sensor

will be tested before actual in‑tank installation.

5. Tighten cord‑grip fitting at the junction box and trim

the wire / cables within the junction box to a 6 or 8

inch (15 or 20 cm) length, then splice the sensor

and console cable / wires together as shown in

Figure 3.

6. Turn console power on for sensor testing.

2