Technical bulletin, Detect mode troubleshooting – Franklin Fueling Systems TS-LS300 Troubleshooting Tips for the LS300 Line Leak Detection System User Manual

Page 2

TECHNICAL BULLETIN

TB0505-01

May 09, 2005

Franklin Fueling Systems • 3760 Marsh Rd. • Madison WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

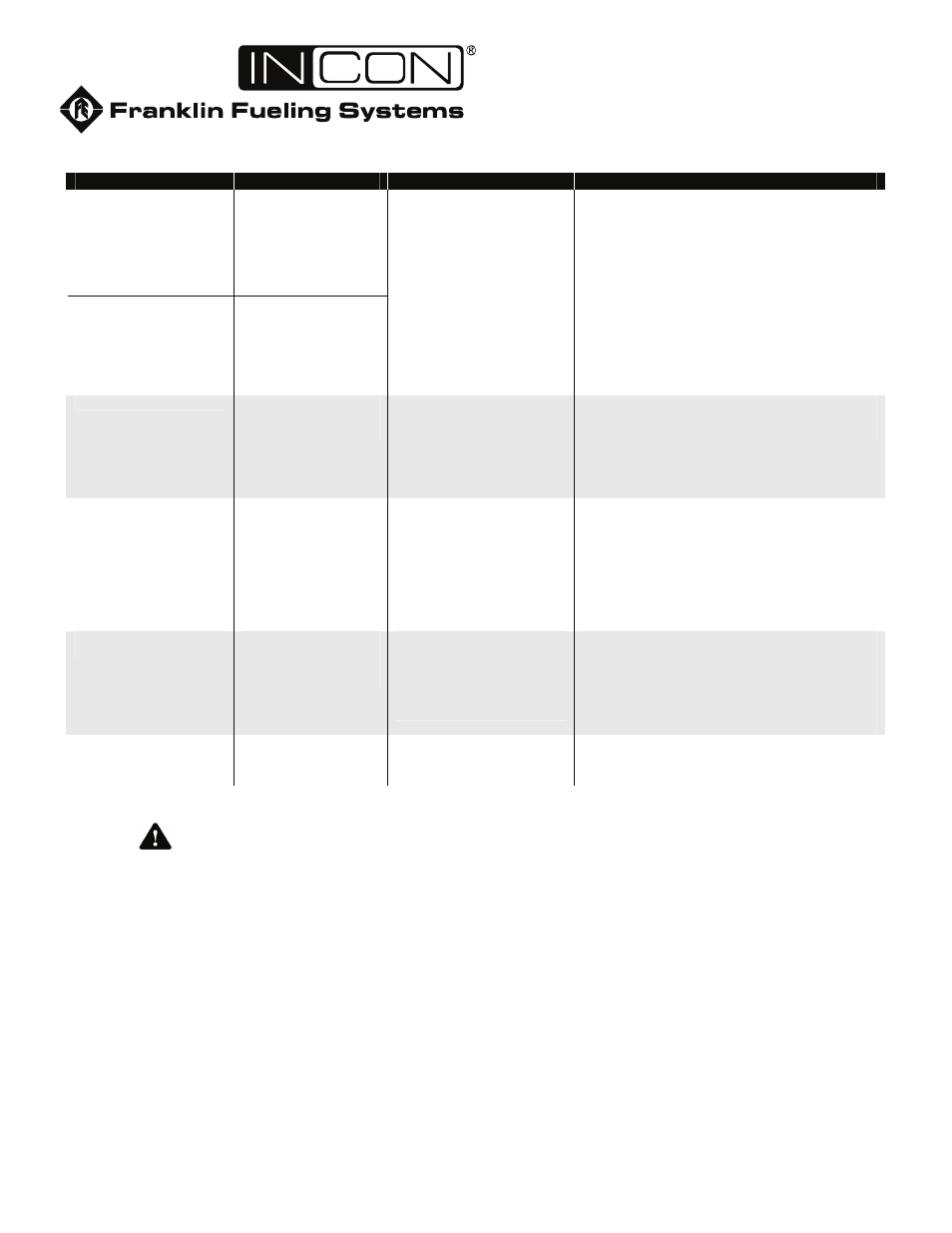

Detect Mode Troubleshooting

Condition

Definition

Potential Causes

Proposed Action

Leak Alarm

• Gross (3gph) Leak

Alarm

The LS300 has detected

a pressure loss

consistent with a leak of

3gph or greater.

• Monthly or Annual

Precision Test Failed

The LS300 has detected

a pressure loss

consistent with a .2gph

leak (one flash) or a

.1gph leak (two flashes).

• Leak in the pipeline

• Submersible pump check

valve not seating properly

• Leak in the manual

pressure relief (FE Petro

Pump)

• Adjustable Functional

Element not seating

properly/defective. (Red

Jacket)

• Push the Test/Reset button to clear alarm.

Conduct a manual leak test to confirm the line

status. If the LS300 again detects a leak after

three failed test sessions, shut down the line and

troubleshoot the pressure loss.

• Check valve seating area should be clean and free

of debris. Clean area if necessary.

• Verify that the manual pressure relief screw (FE

Petro) is turned clockwise.

• Check sump areas for signs of leakage.

• For further information, see FE Petro Service

Bulletin SB007 STP/IST Static Pressure Testing.

Transducer Not Seen

The LS300 cannot

detect the signal coming

from the transducer

• Transducer is wired

incorrectly

• Wiring or connections to the

transducer are loose or

broken

• Transducer is defective

• See the LS300 Auto-Learn User’s Guide‘s

Transducer Troubleshooting section for specific

troubleshooting information.

Pipeline Failed to Hold

Pressure

After the submersible

pump shut off, pipeline

pressure dropped

immediately to 0 psi.

• Large leak in the pipeline

• Check valve removed or

stuck open

• Press Test/Reset button to clear alarm. Conduct a

manual 3gph test and confirm line status.

• Verify that the check valve is installed in the

submersible pump and is seating properly.

• Check sump areas for signs of leakage.

• For further information, see FE Petro Service

Bulletin SB007 STP/IST Static Pressure Testing.

Insufficient Pressure to

Conduct Test

Pipeline is not fully

pressurizing when the

submersible pump is

turned on.

• Power to submersible is

OFF

• Leak in the pipeline

• Transducer problem

• Verify that there is power to the submersible

pump.

• Check sump areas for signs of a large leak.

• See the LS300 Auto-Learn User’s Guide‘s

Transducer Troubleshooting section for specific

troubleshooting information.

Calibration is Incomplete

The line will not detect

leaks because the line is

not Learned

• Learn sequence was not

attempted or was not

completed properly

• See the LS300 Auto-Learn User’s Guide‘s Line

Calibration. Follow the instructions on learning a

line.

Highly flammable vapors or liquids may be present in the environment in which this equipment is

installed or serviced. Installing or working on this equipment means working in an environment that

presents risks of severe injury or death if instructions and standard industry practices are not followed.

Follow all applicable codes governing the installation and servicing of this product and the entire system.

Always lock out and tag electrical circuit breakers while installing or servicing this equipment and related

equipment. Refer to the Installation and Owner’s Manual of this equipment and related equipment for

complete installation and safety information.

Warning