Franklin Fueling Systems TS-LS300 Troubleshooting Tips for the LS300 Line Leak Detection System User Manual

Technical bulletin, Learn mode troubleshooting

TECHNICAL BULLETIN

TB0505-01

May 09, 2005

page 1 of 2

Troubleshooting Tips for the LS300 Line Leak Detection System

The Franklin Fueling System LS300 Line Leak Detection System is a precision electronic line leak detection system designed for

installation in petroleum piping systems. This document should be used as a quick reference troubleshooting guide when problems

or issues occur during the installation or operation of the LS300. For complete installation and operation information, please consult

the LS300 Auto-Learn User’s Guide.

The following sections will focus on the most common problems seen during the Learning process and in Detection mode. For a

complete list of possible conditions, please refer to the LS300 Auto-Learn User’s Guide.

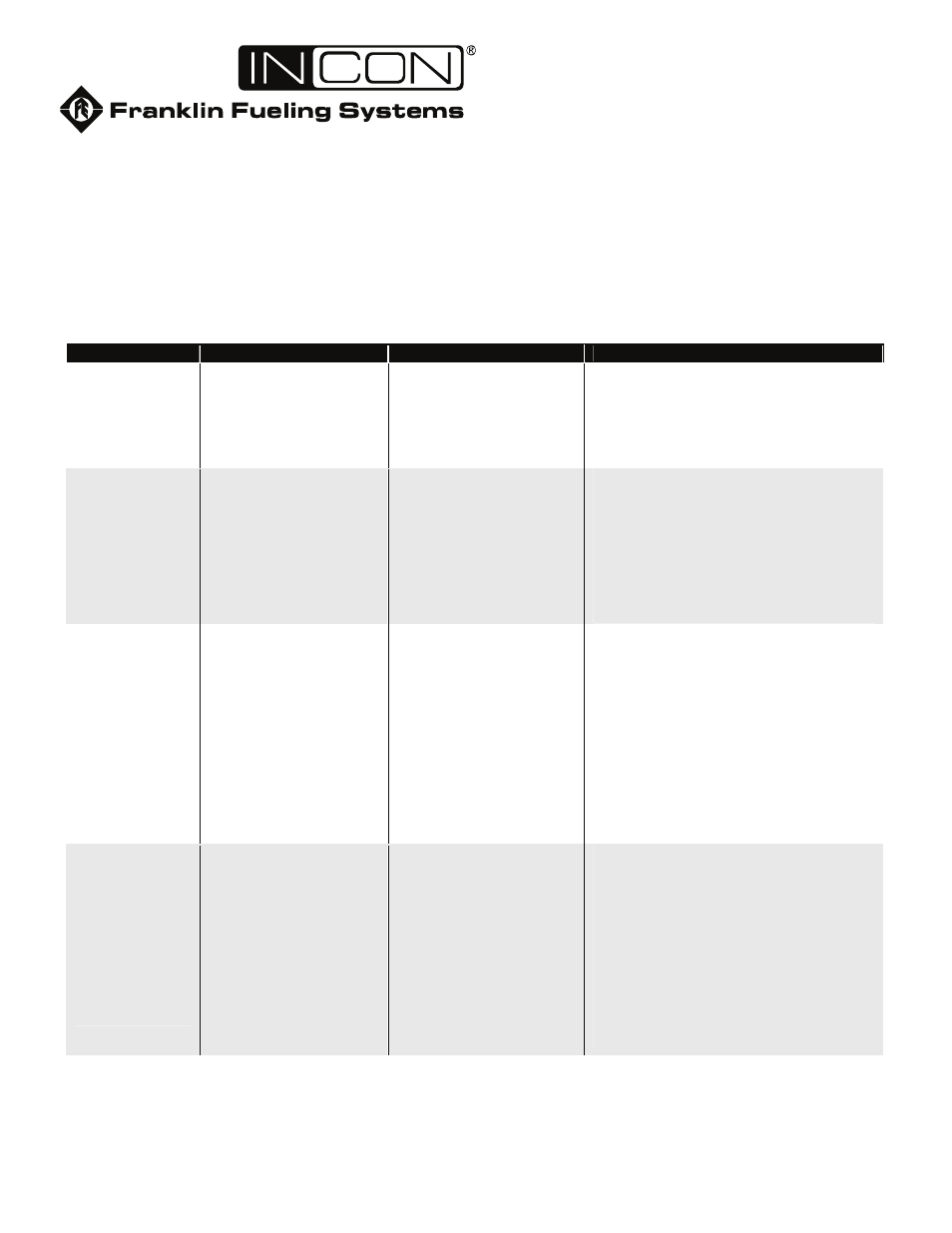

Learn Mode Troubleshooting

Condition

Definition

Potential Causes

Proposed Action

Transducer Not

Seen

The LS300 cannot detect the

signal coming from the

transducer

• Transducer is wired

incorrectly

• Wiring or connections to the

transducer are loose or

broken

• Transducer is defective

See the LS300 Auto-Learn User’s Guide’s

Transducer Troubleshooting section for specific

troubleshooting information.

Insufficient Pressure

Pump pressure did not exceed

17.5 psi upon pump start-up.

• Line pressure was not bled to

zero before calibration

• Power to STP is off

• STP is shutdown due to a

fault or alarm condition

• Transducer problem

• Broken pipe or valve

• Confirm line pressure was bled to zero prior to

attempting the Learn process.

• Confirm power is on to STP and pump controller

is free of alarms.

• Possible transducer problem. Seethe LS300

Auto-Learn User’s Guide’s Transducer

Troubleshooting section for specific

troubleshooting information.

• Check sump areas for signs of leakage.

No Pressure Loss

Detected

Pressure decay was not

detected after pump shut-off.

• Leak generator not installed

or needle valve not opened

• Leak generator clogged

• Transducer problem

• Confirm that the leak generator is installed and

the needle valve is opened completely.

• Observe the leak generator during the Learning

process. Verify that the fuel flow through the

orifice is a steady stream from pump OFF to

zero line pressure. If the stream is not steady, or

line pressure does not drop to zero, replace the

Leak Generating Device, or call Tech Support at

800-984-6266.

• Possible transducer problem. See the LS300

Auto-Learn User’s Guide Transducer

Troubleshooting section for specific

troubleshooting information.

Auto-Learn

Complete

• Piping Modulus is

out of range for

annual (0.1 gph)

test.

• Piping Modulus is

out of range for

monthly (0.2 gph

and annual

(0.1 gph) tests.

During the Learning sequence,

pressure decay was too slow

for the system to accurately

detect a .1 gph and, if

indicated, a .2 gph leak.

• Air is trapped in the pipeline

causing slow pressure decay

• Leak generator is partially

clogged, or needle valve is

not opened completely

• Pipeline exceeds the

maximum pipe length

dimensions for precision line

testing

• Purge line completely, starting at the dispenser

farthest from the pump and working your way

toward the pump. Also open Needle valve while

pump is running, to remove air from that area.

Close the Needle valve and shut off the pump.

• Confirm that the Needle valve is opened

completely, and the Leak generator emits a

constant stream of product. Verify that the leak

generator tube is free of air.

• Check the bleed orifice on the Leak generator,

and look for signs of visible damage. Replace

Leak generator if necessary, do not attempt to

repair.